DONJOY TECHNOLOGY CO., LTD |

|

Verified Suppliers

|

|

SS304 High Performance Hydraulic Check Valves For Avoiding Pipe Hammering

Quick Detail:

Hydraulic Check Valves

Type: Clamped, thread, Welded

Size: Request of customer

Specification

| Product Name: | SS304 Clamped Check Valve,Non-Retention valve with thread type, avoid pipe hammering |

| Valve Body Material: | SS304 or SS316L |

| Seal Material: | EPDM |

| Max. Working Pressure: | 10Bar |

| Opening pressure: | 0.1-0.3bar |

| Max. Working Temperature: | 120 degree C |

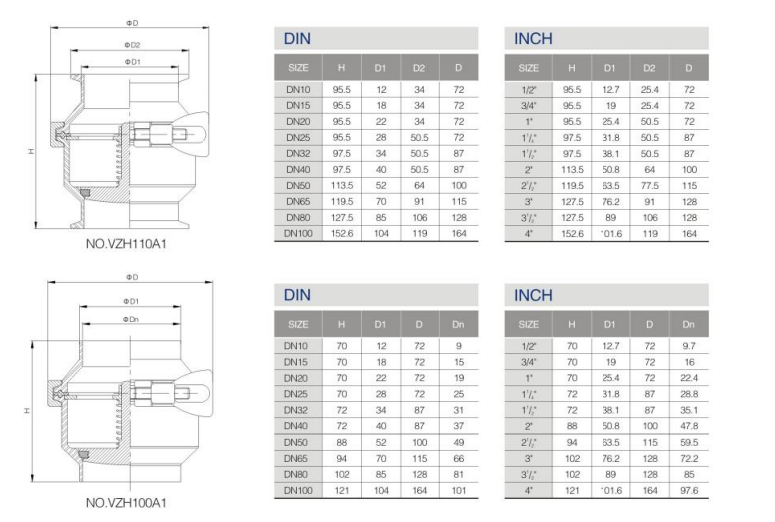

| Availably size: | 1"-4", DN10-DN100 |

| Availably connection: | Thread,Weld,Clamp |

| Availably standard: | DIN,SMS,3A |

| Certificate: | FDA,CE |

Technical Information

• A Sanitary Check Valve can vary in size from 1/2″ to 4″.

• The end connection can be butt-welded, sanitary tri-clamped,

threaded or others upon request.

• The maximum Working Pressure available is 10 bar (145psi)

• Valves are available for the following Cracking pressures:

4.35psi (0.3bar) for DN25

2.9psi (0.2bar) for DN32-40

1.45psi (0.1bar) for DN50-100

• The temperatures at which the valves function depending on

material range from:

EPDM 14°F to 248°F (-10℃ to 120℃)

SILICONE -22°F to 356°F (-30℃ to 180℃)

VITON (FPM) 23°F to 356°F (-5℃ to 220℃)

Teflon (PTFE) -4°F to+482°F (-20℃ to 250℃)

• The Surface finish can be Ra 32μin (0.8μm) as default, or better upon request.

Applications:

1. Check valve is a valve that prevents the fluid from flowing back and ensures to flow in only one direction.

2. It can be used to prevent the flow less from returning avoid pipe-hammering

3. It is used in the food processing,beverages, wine, oil,cosmetics, pharmaceutical and chemical industries.

Things to Keep in Mind When Installing a Sanitary Check Valve

Sanitary Check Valves can be installed horizontally or vertically. However, the following specifications must be followed for ball and disk check valves:

– Ball Check Valve –

In a vertical setting, the product has to flow from bottom to top so that gravity can push the ball in and out of the seat.

In a horizontal setting, the curved portion of the valve needs to be upright and at 90 degrees to the pipe. This makes sure that the valve is free-draining and the ball sits properly.

– Disk Check Valve –

Disk Check Valves are not free-draining in a vertical setting. Therefore, for them to be free-draining, they need to be in a horizontal position.

Drawing

Certificate

Donjoy manufacture products certified by 3A,CE,FDA and so on, according to GMP, EHEDG standard. Production strictly enforce ISO9001-2008 management system.

Tag :One way valve, Spring check valve, Non retention valve