Lantian Precision Machinery Manufacturing (Dalian) Co.,Ltd |

Product Name | Lost Wax Casting Service Foundry Directly Investment Casting Water Valve Parts |

| Material | Stainless Steel, Alloy Steel, Carbon Steel, Aluminum, Copper, Brass or other special material as request |

Surface Treatment | Polishing, Anodizing,Powder Coating,Polishing, Electric-plating,Galvanizing, etc |

| Value-added Service | Silk-screening,Engraving,Cut-out making etc |

| Manufacturing | Redesign, In-house tooling, Casting: Investment Casting,Sand Casting, Diecasting, CNC machining:drilling, milling, threading, grinding etc. |

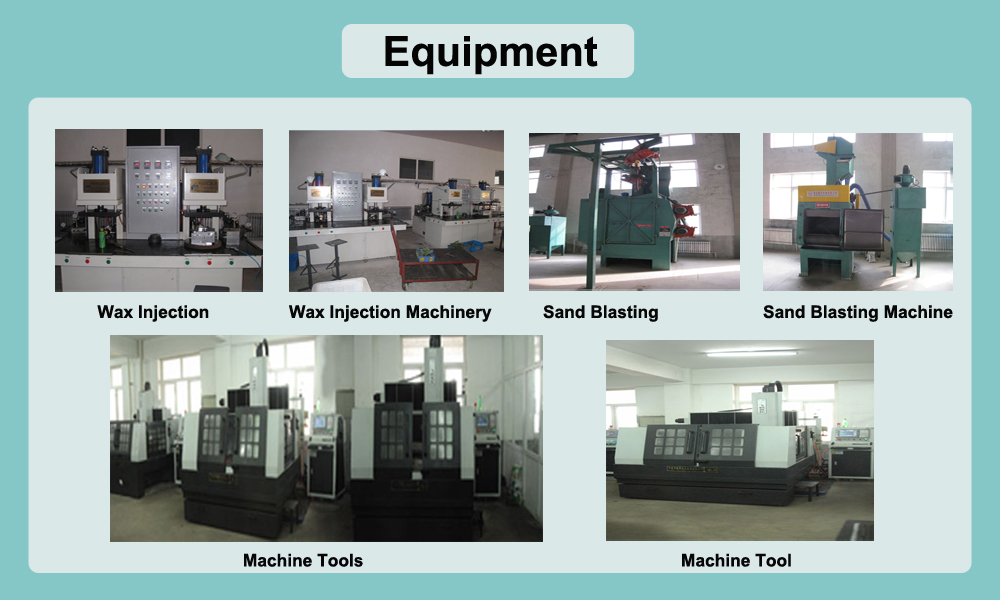

| Equipment | See below |

| Industries Served | Aerospace, Automotive, Agriculture,Construction, Electrical, Electronic, Home Appliance, Medical,Marine, Machinery, Furniture, Food, Lighting,Telecommunication etc |

| QC | 100% Strict Inspection For Every Processing |

| Service | One-stop Service: Custom Design, Fabrication, Assembly And Delivery |

| Working Time | 24*7 hours online avaliable |

DIN, AISI, ASTM, BS, JIS, GB etc

Investment casting also called as Lost wax casting, is the best way

to produce a metal part tby taking accurate, performance, and cost.

Investment casting produces precise components while minimizing the

material waste, energy and subsequent machining work. It also

ensures the production of very intricate parts. Which makes the

investment casting process quite suitable for design engineers.

Our factory, specialized in investment casting and machining

manfuacturing over 23 years, with strong technical support from our

engineers, we produced each year 6000 tons material, and 95% of our

products were exported abroad. We can produce the metal parts

exactly according to your designs or the samples, and the products

can be widely used for automotives and vehicles, ships and vessels,

railway and trains, mining machinery, agricultural machinery,

petrochemical machinery, oil and gas platform, industrial

compoents, construction and sanitary ware etc.

FAQS:

1. Are you a manufacturer or a trading company?We are a professional manufacturer with almost 30 years’ experience for designing and producing investment casting components. |

2.Where can I get product&price information?Send mail to ltcasting@hotmail.com , we will contact you once we received your email. |

3.What is the lead time for sample and mass production?Depends on your specific items, generally around 30-40 days (including tooling make) |

4.How to work with the OEM services?After receiving your design drawings or original samples, we will give some technical proposals and a quotation to you, after your confirmation, will produce for you. |

Q4:What kinds of information do you need to offer for quote?Please provide us the drawings then we will work for you. |