Lantian Precision Machinery Manufacturing (Dalian) Co.,Ltd |

1.Investment casting:

Stainless Steel Casting

Carbon Steel Casting

Low Alloy Steel Casting

Aluminium Casting

2.lost wax casting;

Sodium silicate Casting process,

Silica Sol Casting process.

Composite Mould Casting Processing

1. Carbon steel;

2. Stainless steel;

3. Low alloy steel;

4. Aluminium

0.05KGS~80KGS

Normalizing

Quenching

Tempering

Renealing

Blacken

Anti-rust Oil

Galvanized

Zinc-plating

Anodizing

Powder coating

Paiting

Other treatment per request

Redesign: We can help our client redesign the products per request to improve the performance of products or production process. Send us the drawing, we can also work for you, type of 2D or 3D drawings are acceptable. |

In-house Tooling: Tooling make is the first step to start lost wax casting, such tooling or pattern will be machined by CNC machine center,So tooling cost needs your payment on the cost when you place the sample order. It is just one-off paid. We will not charge you again for future orders. |

Casting: Lost Wax/Investment casting: Water Glass Casting process and Silica Sol Casting Process,and also a process combined. Sand Casting, Die Casting |

CNC Machining: CNC Turning, Milling, Drilling, Boring, Threading, Grinding. |

Heating Treatment: Normalizing,Annealing,Tempering,Quenching, Aging, |

Surface Treatment: Sand blasting,Zinc/Chrome/Nickel plating,Powder coating, Anodizing,Galvanized, Painting, Oxidation, Mirror Polish |

Established in 1997, till now we have more than 20 years experience in investment casting processing with four branch factories, our process includes sodium silicate process, silica sol process, compound process and our material covers stailess steel, carbon steel, low alloy steel. Our products weight range is from 0.05kgs ~80 kgs, our products are widely used in railway, ships, automobiles, engines, machinery, and petrochemical field.

Currently the company has 4 branch factories and covers an area of 19000.00 square meters, total assets is over 40 millian RMB, we have one sodium silicate processing foundry, 1 silicon sol processing foundry,1 machineryh processing and 1 mold processing plant, also one sales company Dalian Yemi Tech, total employees is over 400, and including 40 engineers and managers.

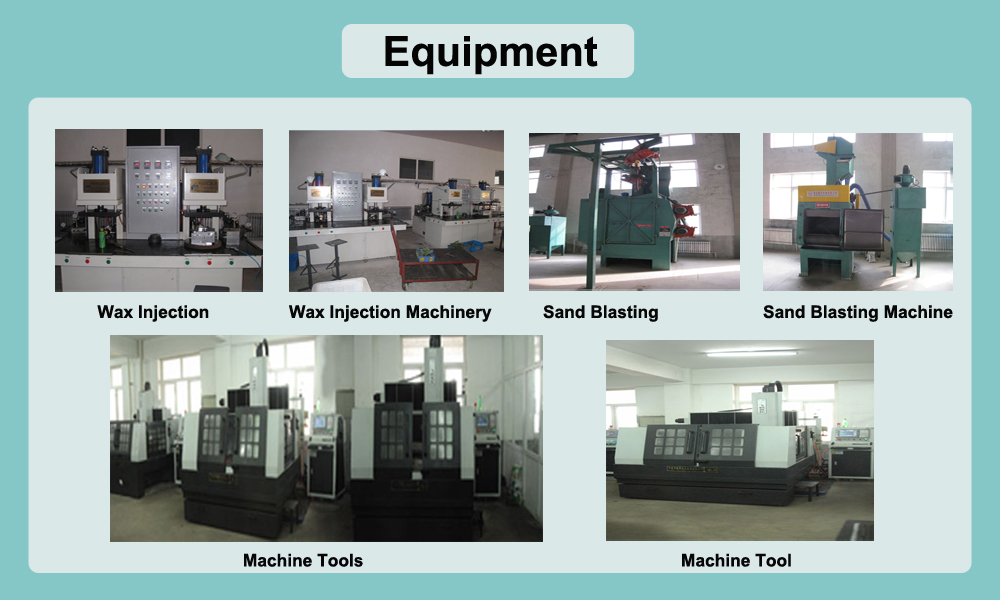

The company has advanced casting machinery,including:

Sodium Silicate Processing Machinery:

Wax injection machines,

Shot blasting machines,

Grinding machines,

Blender,

DC Arc Welding Machines,

Intermediate Frequency Induction Electric Furnace,

Box type resistance Furnace,

Burning Kiln,

Silica Sol Processing Machinery:

Wax liquid treatment three-piece,

Wax injection machines,

Industrial cold water machines,

Moistening slurry machines,

Sand machines,

Spray sand machines,

Full automatic demineralized water controller,

Filter,

Die Machines,

Resistance Furnace,

Crawler shot blasting machine,

Double hook shot blasting machines

Fabrication Machinery:

Vertical Machining Center,

Cnc miling machine,

Vertical milling machine,

Cnc machine tools,

Universal radial milling machine,

Radial drilling machine,

Engine lathe,

Bandsaw machine,

Bow sawing machine,

Wire cutting machine tools

| FAQS |

1. Are you a manufacturer or a trading company?We are a professional manufacturer with almost 30 years’ experience for designing and producing investment casting components. |

2.Where can I get product&price information?Send mail to ltcasting@hotmail.com , we will contact you once we received your email. |

3.What is the lead time for sample and mass production?Depends on your specific items, generally around 30-40 days (including tooling make) |

4.How to work with the OEM services?After receiving your design drawings or original samples, we will give some technical proposals and a quotation to you, after your confirmation, will produce for you. |

Q4:What kinds of information do you need to offer for quote?Please provide us the drawings then we will work for you. |

Sales: Angie Pan

Email: ltcasting@hotmail.com

Mobile: 0086-13478609753