JUNENG MACHINERY (CHINA) CO., LTD. |

|

Verified Suppliers

|

|

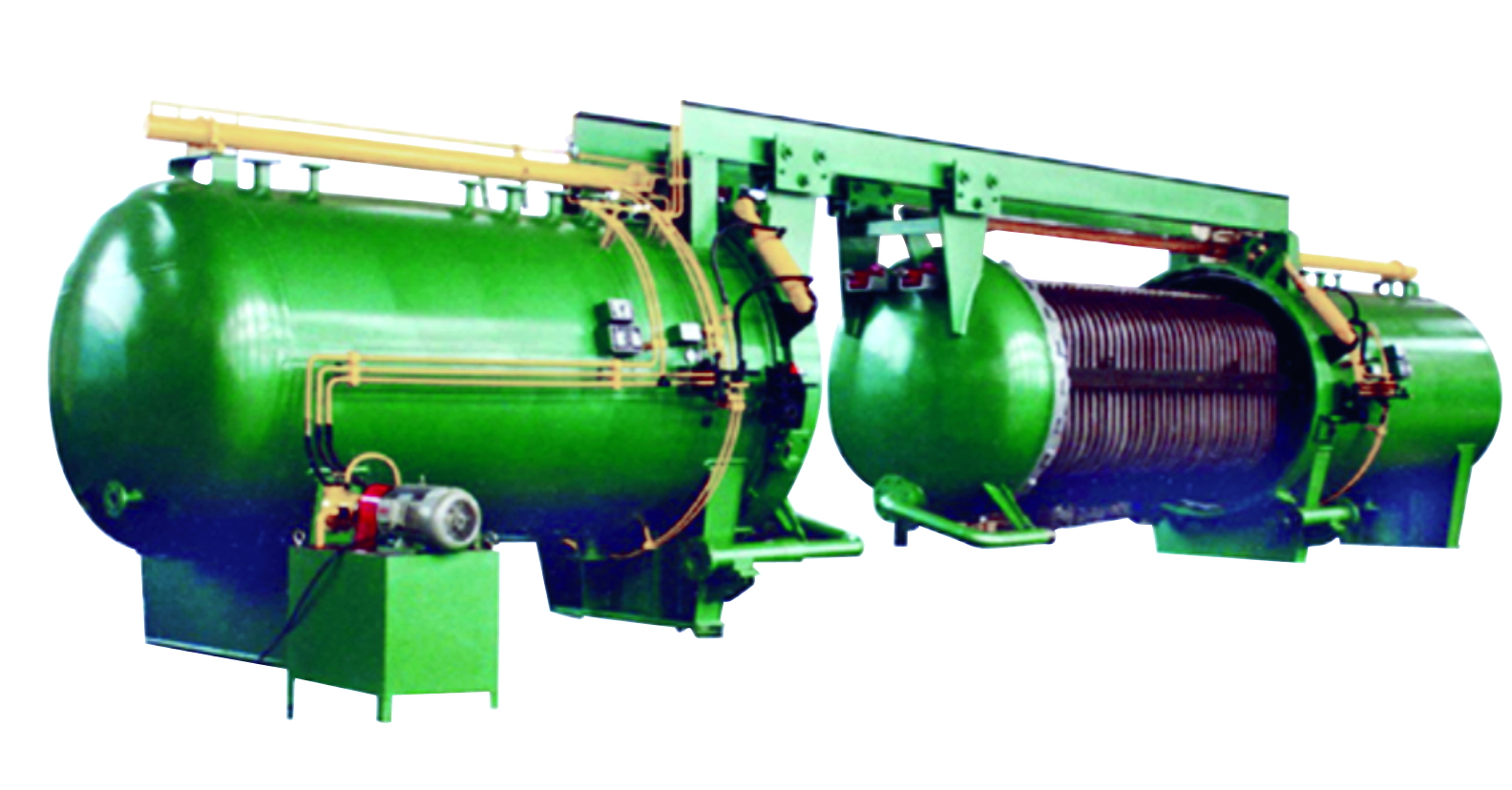

Auto Cake Discharging Horizontal Pressure Leaf Filters For Sunflower Oil Dewaxing

Application:

Food industry : Syrups, edible oils, dewaxing , decolour, degrease

Chemical industries: Sulphur, aluminum sulfate, Polyaluminum chloride, plastic,

dyestuff intermediate, bleaching liquid, lubricant additives and

intermediate and high pressure polyethylene, etc.

Dry, semidry cake and clean filtrate recovery.

Product description:

The filter body is designed as a horizontal cylinder, and the lower support structure is set. The filter cover is fixed, and all the nozzles such as the filter inlet, outlet, drain, blast, overflow, and vent are fixed on the cover.All nozzles do not need to be disassembled during operation.When the slag is discharged, the cylinder moves, the operation is convenient, and the structure is reasonable.

This product realizes filter without the filter paper and cloth , and the filtration is enclosed prevent environmental pollution, the labor intensity is low thanks to automatic dreg removal.

Note: The locking device can only be released under pressure free and no material circumstance, then the screen can be pulled out to carry out dreg discharging.

Product competitive advantage:

1, Fully hermetic filter , no leakage, no pollution.

2, Filtering gauze flakes can be pulled out automatically, and easy

to be inspected and cleaned.

3, As the leaves filtering on both sides, large filtration area and

solids holding capacity can be obtained.

4, Automatically residue discharging by which labor can be largely

reduced.

5, Controlled by hydraulic thus automation is to be.

6, A large filtration area and large solids holding capacity can be

obtained .

Product Specifications:

Area series ( ㎡) | Shell diameter series ( mm) | Work pressure ( Mpa) | Work temperature | Proximate treatment | |

5, 10, 15, 20, 25, 30, 35, 40, | 900, 1200, 1400, 1500, 1600, | 0.4 | 150 | Oil | 0.2 |

|

| Beverage | 0.8 | ||

History:

Juneng Group was established at 1987. It has 36 years history. Now its three production bases with a total capacity of 280000 square meters in Nanjing City and Yixing City of Jiangsu Province.

Juneng’s success is contributed by the commitment of every member of the Company. In addition, the specialty and potential of each member is being respected and disinterred.