Zhengzhou Baiyun Industrial Co., Ltd. |

|

Emark Certificated Auto Brake Pads No Noise 100% Green Tested

NATIONAL LEADERSHIP

In the braking system industry Baiyun is the undisputed National

leader in the production of

brake friction material. With its unrivalled expertise, Baiyun produces high performance

brake pads for the most popular cars in the European, American and Japanese markets.

The superlative levels of technology and reliability of Baiyun products is founded on an

integrated production process which encompasses every stage in the production process, from

research and development and testing to casting and machining.

On top of this is an ongoing commitment to research and development that sets Baiyun apart as a

leading name in its industry and allows the group to excel as both a manufacturer of reliable,

durable brake pads for the world's most popular and widely sold cars, and as a supplier of

state-of-the-art brake pads designed and produced specifically for the most exclusive and

desirable models in every class.

Passenger car brake pad

● Excellent and stable braking performance

● Excellent heat resistance, excellent braking

performance even at high temperatures

● Small damage to the disc, do not often replace the disc

●It is not easy to have sound or noise wear resistance, can run longer mileage

● Metal free, stable performance in extreme cold and hot climateHeat treatment

Equal ratio pressure hot pressing unit

Features:

● Each station’s hydraulic and electric controlled separately.

● Each station 4-8 antrum molds are equal ratio pressed. Same density of every pad is

guaranteed.

● All process parameters display on screen.

● Real-time online control. Fault & overlimit will result in automatic alarming.

| Item Name | Car Brake Pad |

| Reference No | FMSI, FERODO, WVA, OE, GDB, MK AND SO ON. |

| Formula | Semi-metallic, Low-metallic , Ceramic |

| Accessories | Shim, sensor, kits as request |

| Package/LOGO | Neutral box, Camlorsini color box or Customized packaging |

| MOQ | 500 sets per item for brake pads |

| Payment | 30% in advance, 70% balance before the shipping. ( Products phots and Package photos will be provided before you do the balance.) |

| QC | 1. Sample Checking 2. Before mass production, material checking and mould checking 3. Technicians self check in production 4. Engineer spot check 5. Packing check 6. Check again before shipping |

Brakes Production process

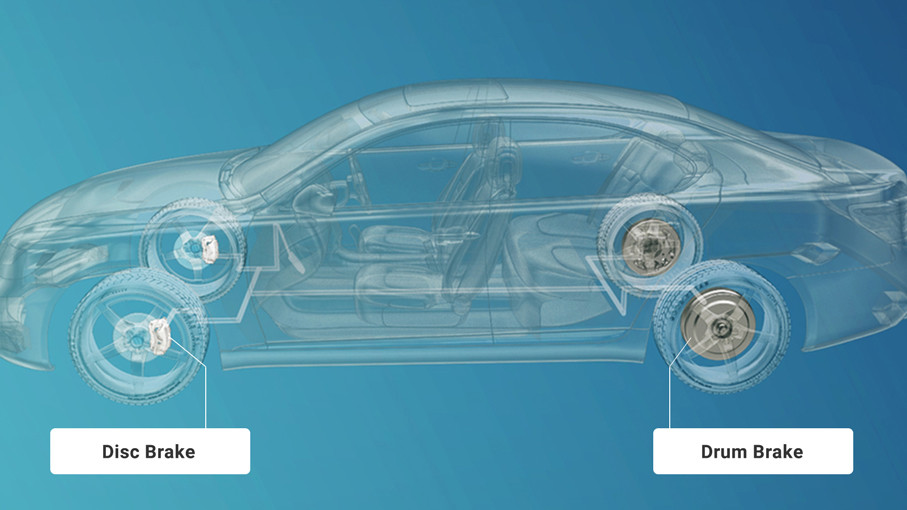

1). Production process of drum brake linings for commercial

vehicles:

Stir ingredients -- -- -- -- -- - > pressure molding (pressing

blank + pressure molding) -- -- --

-- -- -- -- -- -- -- -- - > > heat treatment chamfering, grinding inside arc -- -- -- -- -- - >

-- -- -- -- -- - > drilling grinding outer arc rubbing surface -- -- -- -- -- - > brush ash

printed label -- -- -- -- -- - > thermoplastic packing -- -- -- -- -- - > artificial packing

packaging

2). Production process of disc brake pads for passanger cars:

Ingredients stirring + polishing of the steel back -- -- -- -- -- -

> glue -- -- -- -- -- - >

pressure molding - -- -- -- -- -- -- -- -- -- -- - > > heat treatment friction surface grinding,

chamfering, slot -- -- -- -- -- - > spray painting -- -- -- -- -- - > the silencing pills -- --

-- -- -- - > surface coated -- -- -- -- -- > spring, three jaw -- -- -- -- -- - > thermoplastic

packing -- -- -- -- -- - > artificial packing packaging

3). Production process of disc brake pads for commercial vehicles:

Ingredients stirring + polishing of the steel back -- -- -- -- -- -

> glue -- -- -- -- -- - >

pressure molding - -- -- -- -- -- -- -- -- -- -- - > > heat treatment friction surface grinding,

chamfering, slot -- -- -- -- -- - > spray painting -- -- -- -- -- - > laser marking loading -- --

-- -- -- - > spring -- -- -- -- -- - > thermoplastic packing -- -- -- -- -- - > artificial

packing packaging

Advantage of BAIYUN

PROFESSIONAL TEAM: Since 1977, focus on brake over 40 years;

Drafting unit of China

friction&sealing material industry standard

OEM & ODM: Top 10 of enterprises in friction material industry of China; OEM & ODM quality and

service

EXCLUSIVE FORMULA: Safety, Comfortable,Asbestos-free,Wear-resisting,Heat-resisting,Less noise,

Less disc injury

CERTIFICATE: ISO9001, ISO/TS16949, E-Mark, Link-Test Report, Greening-Test Report, SGS,MA,CNAS