Ours ultrasonic Co.,Ltd |

|

how to mount ultrasonic cleaning transducer for cleaning tank![]()

Introduction of ultrasonic oscillator:

Ultrasound vibrator, also known as ultrasonic vibrator, ultrasonic

vibrator, is a kind of ultrasonic transducer, is the core component

of the ultrasonic cleaning machine. Industry standard name:

ultrasonic transducer, belongs to piezoelectric ceramic material,

one of the main parts of ultrasonic cleaning machine. In terms of

power, the single ultrasonic head is 60W and 100W. Frequencies are:

20KHZ, 25KHZ, 28KHZ, 40KHZ, 68KHZ, 80KHZ, 100KHZ, or higher,

respectively; from the shape of the difference is: straight column,

horn, or higher.

Characteristics of ultrasonic oscillator:

1. High performance: high mechanical Q value, high conversion

efficiency and good quality; 2. ultrasonic oscillator transducer,

large amplitude, excellent performance; 3. ultrasonic oscillator

transducer, heat resistance: piezoelectric ceramic material has

good heat resistance, can expand the use of temperature range, at

the same time, high Q value, small resonant impedance, low

calorific value; 4. ultrasonic oscillator transducer product

appearance clean, rust-free. No obvious depression or scratch.

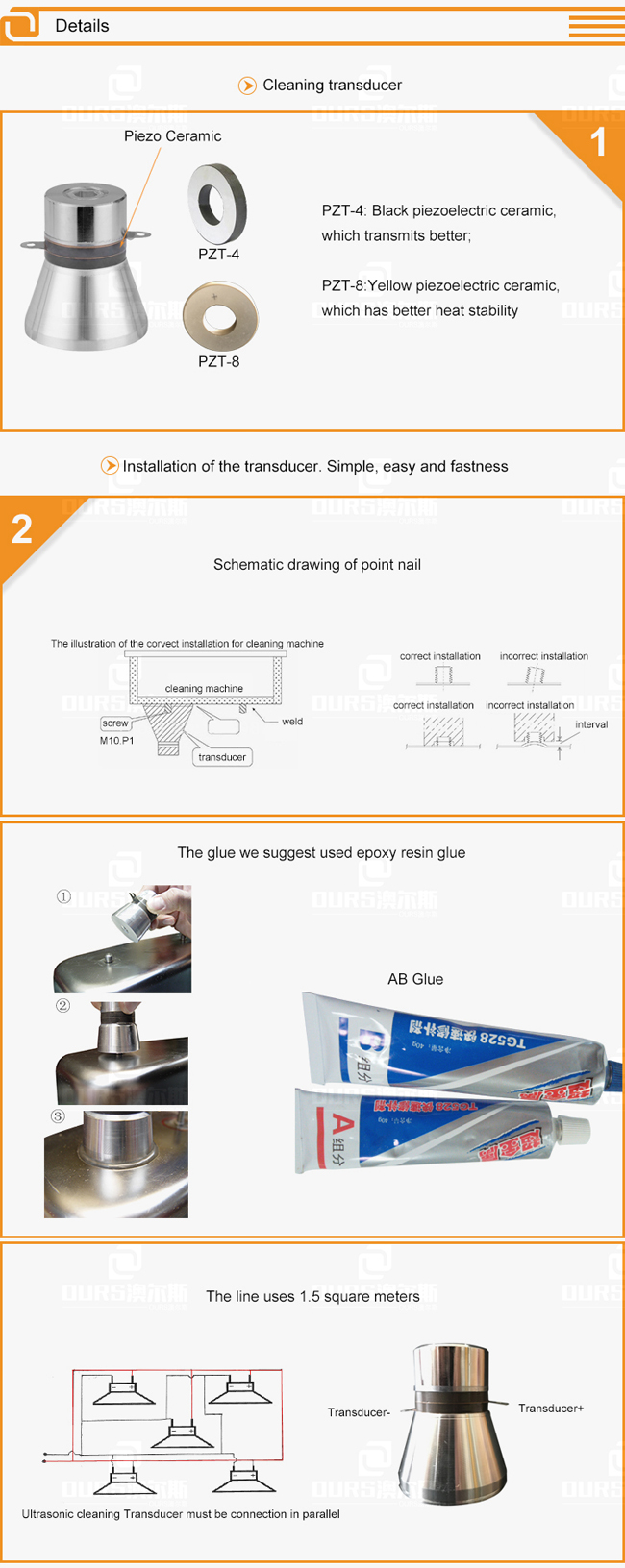

Installation technology of ultrasonic vibration head:

1. Preparatory tools: Argon arc welding, No. 10 inner hexagonal

wrench, chrome-iron-tin wire, 2.5 square high temperature wire,

2*2.5 cable line, oscillator glue, (stripping pliers, casing,

tie-up, sand blasting machine, pipe fittings, etc.). 2. Welding

screw: Calculate the arrangement position of the oscillator, weld

the screw in the cleared position, then clean the screw around,

make sure it is flat, so as not to affect the installation of the

oscillator. 3. Glue disposition: mix glue evenly according to the

prescribed proportion. (Merry, Eroda, 4030 glue mixed before

bonding, KMD398 glue mixed in the bonding process). 4. Install the

vibration head: Apply the glue evenly on the bottom of the

ultrasonic oscillator, gently twist the air and excess glue between

the bottom of the transducer and the contact surface of the

cylinder bottom, so that the oscillator is more closely integrated

with stainless steel. Fifth, solidification and condensation:

solidification at relatively high room temperature, 4-8 hours

wiring, 24 hours after power test machine, test machine absolutely

not allowed to be empty vibration. Note: 1. Metal seed nailing

machine can also replace argon arc welding. 2. Welding screw must

be fully welded, otherwise it is easy to fall off. 3. Regarding

curing, the length of time should consider temperature, low

temperature for a long time, high temperature for a faster time. It

is recommended to operate at room temperature, even if heated, do

not overheat, appropriate and best.

Features:

1. Low heat

2. Good thermal stability

3. Frequency and static capacitance consistency strong.

4. Resonance impedance is low.

5. The average length of life.

6. It can be widely used in a variety of ultrasonic cleaning

equipment.

7. High performance: mechanical Q value, high vibration efficiency,

high amplitude

Payment Terms:Prepaid by Bnak, T/T and West Union, ect.

Technical support: All our products adopt advanced technology, produce product with

advanced system, all worker are experienced and skillful.

| Type | Length(mm) | Weight(g) | Frequency(KHz) | Resonance Impedance (Ω) | Static Capacity (pF)±10% | Input Power(W) |

| ARS-QXHNQ-20100 PZT-8 | 94 | 900 | 20 | 10-20 | 5200 | 100 |

| ARS-QXHNQ-25100 PZT-4 | 77 | 710 | 25 | 10-20 | 6600 | 100 |

| ARS-QXHNQ-28100 PZT-8 | 66 | 625 | 28 | 10-20 | 5200 | 100 |

| ARS-QXHNQ-28100 PZT-4 | 66 | 624 | 28 | 10-20 | 6600 | 100 |

| ARS-QXHNQ-30100 PZT-8 | 61 | 555 | 30 | 10-20 | 5200 | 100 |

| ARS-QXHNQ-2560 PZT-4 | 77 | 530 | 25 | 10-20 | 5400 | 60 |

| ARS-QXHNQ-2860 PZT-8 | 68 | 470 | 28 | 10-20 | 3800 | 60 |

| ARS-QXHNQ-2850 PZT-4 | 82 | 425 | 28 | 10-20 | 4100 | 50 |

| ARS-QXHNQ-3360 PZT-8 | 58 | 420 | 33 | 10-20 | 3800 | 60 |

| ARS-QXHNQ-4060 PZT-8 | 55 | 300 | 40 | 10-20 | 3800 | 60 |

| ARS-QXHNQ-4060 PZT-4 | 56 | 310 | 40 | 10-20 | 5400 | 60 |

| ARS-QXHNQ-4050 PZT-4 | 54 | 260 | 40 | 10-20 | 4100 | 50 |

| ARS-QXHNQ-4050-1 PZT-4 | 57 | 300 | 40 | 10-20 | 4100 | 50 |

| ARS-QXHNQ-5435 PZT-4 | 36 | 135 | 54 | 10-20 | 3200 | 35 |

| ARS-QXHNQ-6860 PZT-8 | 80 | 460 | 68 | 10-20 | 3800 | 60 |

| ARS-QXHNQ-68120 PZT-4 | 67 | 588 | 68 | 10-20 | 7800 | 120 |

| ARS-QXHNQ-8060 PZT-4 | 60 | 325 | 80 | 10-20 | 5400 | 60 |

| ARS-QXHNQ-12060 PZT-4 | 56 | 260 | 120 | 10-20 | 5400 | 60 |

| ARS-QXHNQ-13550 PZT-4 | 54 | 215 | 135 | 10-20 | 4200 | 50 |

![]()

Packing: how to mount ultrasonic cleaning transducer for cleaning tank

how to mount ultrasonic cleaning transducer for cleaning tank