Horizontal Measuring Projector Marble Base Large Screen 5X-100X

Lens 2D High Accuracy

1.1Application

PH series of Digital Horizontal Measuring Projector, is a light,

machine, electricity, calculator integration of precision and

efficient optical measuring instruments, it is widely used in

machinery, instrumentation, electronics, light industry and other

industries, institutions, research Therefore, the metrology

department, laboratory and production workshop. The instrument can

efficiently detect the contours of various shapes of complex work

piece size and surface shape.

1.2Technical Parameters

| Name | Digital Horizontal Profile Projector |

| Model | PH400-3015 |

| Code# | 512-400 |

| Table Size | 455x126mm |

| Table Travel | 300x150mm |

| Focus | 120mm |

| Accuracy | ≤3+L/200(um) |

| Resolution | 0.0005mm |

| Load-Bearing | 15Kg |

| Projector Screen | Diameter :412mm,Measuring Range ≥ Ø400( “M” Line) |

| Rotation Angle 0~360° ; Resolution: 1’or 0.01°,Accuracy 6’ |

| Count | DP400 (510-340) Multi function color LED data processor |

| Illumination | Transparent Illumination:3.2V/10W LED |

| Reflected Illumination:220V/130W LED |

| Operating Environment | 20℃±5℃,Humidity 40%-70%RH |

| Power | AC110V/60Hz; 220V/50Hz,200W |

| Dimensions (L×W×H) | 1099x1455x633mm |

| Packing Size(L×W×H) | 1157x1355x653mm |

| Net/Gross Weight | 350/300kg |

1.3 Objective Lens

| Objective Lens | 5X(Option) | 10X(Standard) | 20X(Option) | 50X(Option) | 100X(Option) |

| Working Distance (mm) | 93.7 | 80 | 67.7 | 48 | 35 |

| View Distance | Φ80 | Φ40 | Φ20 | Φ8 | Φ4 |

1.4 Illumination System

1.4.1 Transparent Illumination:3.2V,10W LED(Lighting focusing

system)

1.4.2 Reflected Illumination:220V/130W LED

1.4.3Cooling Mode:Force-Air Cooling(Transparent use one fan and

reflected use one fan)

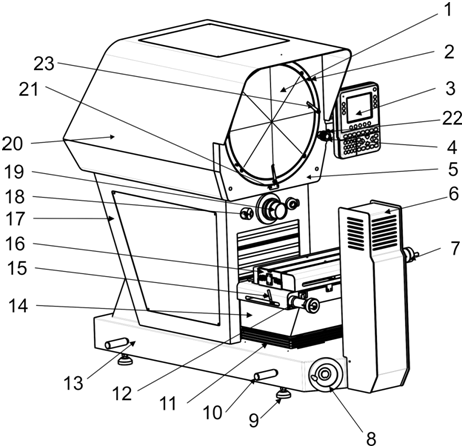

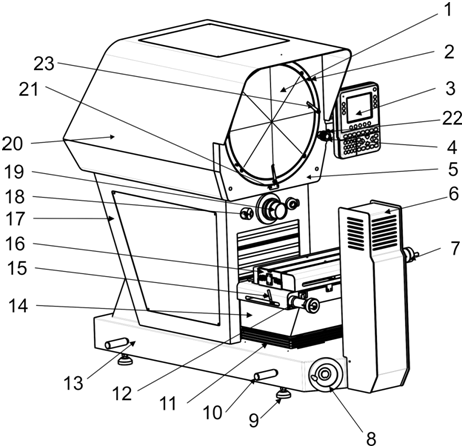

| 1. Projection Screen | 2. Screen rapid movement knob | 3. DP-400 Counter |

| 4. Screen rotating knob | 5. Projector frame | 6. Transparent Illumination |

| 7. X axis knob | 8. Rising Knob | 9. Footing |

| 10. Carry Handle | 11. Dust Cover | 12. Y-axis |

| 13. Base | 14. Vertical Workbench | 15. Hinge |

| 16. Stage | 17. Down Body Shell | 18. Reflected Illumination |

| 19. Objective Lens | 20. Up Body Shell | 21. Zero Mark |

| 22. Lock Screw | 23. elastic clamp | |

Maintenance

This chapter explains the daily maintenance that must be performed

on the measuring projector PH-400 series, including cleaning and

the replacement of consumable parts.

- Temperature: The PH-400 series measuring projector has been

assembled and adjusted 20℃ in a temperature controlled room. To

ensure the rated measuring accuracy, the temperature at the

installation site must be maintained as close to 20℃ as possible,

with minimal fluctuation. In poor temperature conditions, the

accuracy performance may not be satisfied. It is illegal to make

any machine adjustments affecting the accuracy at ambient

temperatures other than 20℃. After such adjustment, accuracy is no

longer guaranteed at 20℃.

- Humidity: Humidity will not affect the measuring accuracy directly.

However, high humidity may corrode machined surfaces and may

adversely affect electronic parts. The environmental humidity

should be maintained within a range of 55% to 60% RH.

- Dust and dirt: The PH-400 series measuring projector consists of

high precision parts, including guide faces, linear scale units,

and optical unit, that must be kept free of dust and dirt. Use and

store the PH-400 series measuring projector in a place where it

will not be subjected to dust and dirt.

- Projection Lens: Compared with ordinary hard glass, the optical

glass of the projection lens used for the projector is soft and

subject to scratches. In order to remove dust do not use a cloth to

wipe the lens, but use a blower brush instead. To remove oil or

fingerprints, dampen clean gauze with a mixture of high grade

alcohol and ether in a ratio of 8 to 2, and wipe gently using a

circular motion.

For lens storage, replace the lens cap and store it in its case.

Also replace the lens cap when the projector is not in use,

although the lens does not have to be removed from the projector.

- A projection screen working surface grinding surface, try to avoid

touching the use. When used for a long time, the screen is dust,

oil accumulation, influence of image clarity. At this time, the

user can use a clean wet gauze dipped in a little neutral detergent

the projection screen wipe gently, stains removed, then wipe clean

wet gauze with a few times, to wipe the lotion. Gauze dipped in

water can not be too much, so as not to drop to the bench and other

metal surface rust, also can be covered with plastic film table.

This work if users have difficulty, also can ask manufacturers do.

- Instrument metal bare surface, with a regular or regular use of

aviation gasoline wipe clean, and then coated with anti rust grease

to prevent rust.

- Instrument cooling fan work is normal, the normal use of the

instrument, the lamp life is directly related to the user should

always pay attention to this problem, and found that it is not

normal should be timely notification to manufacturers overhaul.

- Mirror (surface reflecting mirror) Since the mirror used in the

projector is silvered on its front face rather than on its back,

unlike ordinary mirrors, it is highly subject to scratches. Ensure

it is free from dust or oil. Should the mirror become stained, use

the same cleaning procedure as for the projection lens. Greater

precautions, however, are required for handing the mirror.