Plastic materials: | ABS, PC+ABS, PP, PPS, PE, HIPS, PVC, PET, PC, POM,

PA66, PBT+GF30%..etc. |

Other materials: | Rubber, Silicone rubber, aluminum, zinc...Metal etc. for casting

mould |

Quality: | ROSH and SGS standard, in house to control 100% inspection |

Feature: | Non marking and Non flash is base request, meet client engineering

well. |

Color, Quantity, Unit price, Tooling cost, Tooling size: | Have color standard to control, will be discussed with client to confirm |

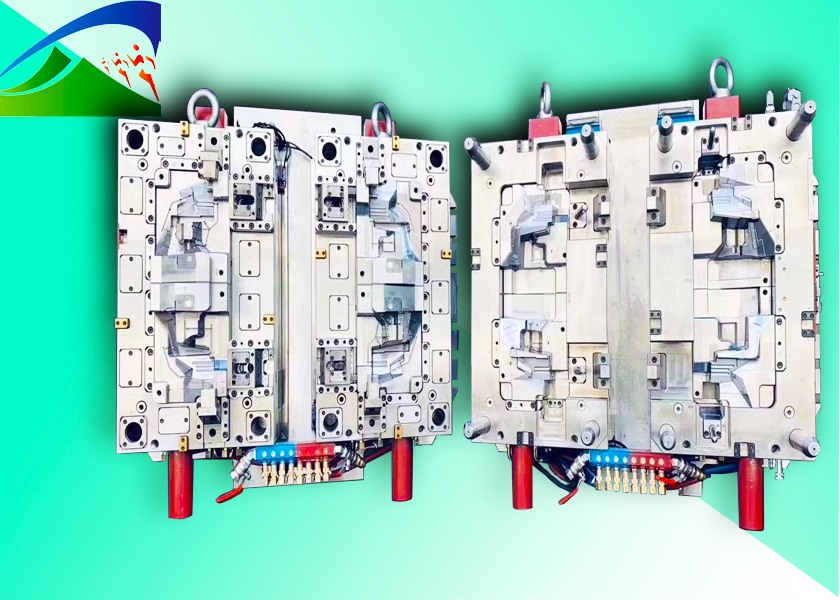

Mold structure: | Custom Closure Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Plastic Frame Mold, Overmould, 2k mould, Collapsible Core Mold,

Blow Mould, Cold runner system LSR Mold etc. |

Mould Base: | HASCO standard, European standard, LKM standard & World

standard etc. can meet |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. as per customer’s requirement. |