Foshan Xiong Qi Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

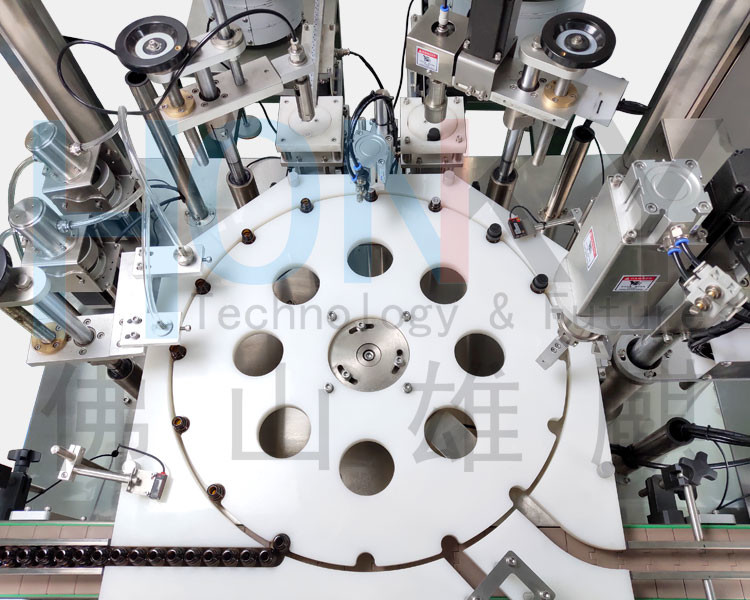

Full Automatic 100ml Essential Bottle Vial Filling And Capping Machine With Servo Capping System For Essential Oil Fill

Characteristic of Full Automatic 100ml Essential Bottle Vial Filling And Capping Machine

The XQJYP-2A is a state-of-the-art filling and capping machine specifically designed for glass bottles used in essential oil packaging. This equipment has undergone rigorous testing to ensure compliance with GMP certification standards, guaranteeing the highest level of quality and safety in its operations.

The liquid filling component of the machine employs an XQX2 high-purity ceramic pump, renowned for its exceptional measuring accuracy and repeatability. This pump ensures precise metering and consistent filling across all production runs, guaranteeing the integrity of the packaged product.

The mechanism for bottle feeding, cap loading, and capping is designed for rapid and efficient operation. This ensures a high throughput rate without compromising on the quality of the final product.

The exterior of the machine is constructed from 304 stainless steel, providing excellent resistance against corrosive liquids. This material choice ensures durability and longevity, even in harsh industrial environments.

The capping section incorporates SERVO torsional screwing technology, ensuring secure and tamper-evident closures without damaging the lids.

This ensures the tightness and integrity of the sealed product, providing peace of mind to both manufacturers and consumers.

Overall, the XQJYP-2A offers a reliable and efficient solution for glass bottle filling and capping in essential oil packaging applications. Its advanced features and robust construction make it a standout choice for manufacturers seeking to achieve GMP compliance and ensure product quality.

Technical data of Full Automatic 100ml Essential Bottle Vial Filling And Capping Machine

Target Products | Essentail oil bottle |

Manufacturing speed | 40 PCS / minute |

Power | AC 220V 50-60Hz / 1.5kw |

Air range | 0.5-0.7Mpa |

Product Display of Full Automatic 100ml Essential Bottle Vial Filling And Capping Machine

The compatible design combines the filling, cap loading, and capping in one small space.

Advantages for using the ceramic pump:

1. Low Friction, Increased Packing Life

2. Extreme Wear Resistance

3. Increased Corrosion Resistance

4. Improved Anti-Galling Surface

Application area

1. ODM and OEM products design;

2. Automatic manufacturing line design;

3. Cosmetic product packing;

4. Pharmaceutical and bio-reagent product packing;

5. Laboratory Liquid dispensing;

6. Lithium Battery Liquid dispensing;

7. Ceramic pump and ceramic pump part design;

8. Other area's material filling;

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support.

Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime

after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine

purchases. We will provide the user manual and videos to support

installing, debugging, operation of the machine, which will

indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.