Shenzhen Xinwangtai Precision Mould Products Co., Ltd. |

|

Product name : Sensor shell

Material: stainless steel sheet coil stock.

Finish: polishing

Place of Origin : Shenzhen , china

MOQ: As required

OEM & ODM: Support

Certificate: ISO 9001:2008

Lead time : It depends on the quantity required

Trade term: EXW, FOB, CIF

| Product name | Sensor shell |

| Materials | Stainless steel sheet coil stock |

| Thickness | 0.4mm |

| Product size | Customized as required |

| Post processing | Polishing, plating |

| Shapes | Various shapes are available |

| Customized shapes/designs are accepted | |

| Application | it is widely used for machine manufacturing, industrial process control system, electronic products,Communication electronic products, consumer electronics, dedicated device etc. |

| Advantages | Expert in producing OEM parts: industry is a professional OEM service provider for metal stamped, machined, deep drawn and sheet metal formed parts with various finish |

| Our factory is located in shenzhen, which can save transportation time and cost | |

| We also have experienced technical personnel who are engaged in technical development | |

| Our skilled workers, professional engineers and excellent foreign trade team always keep passion to support our customers |

2. Main range:

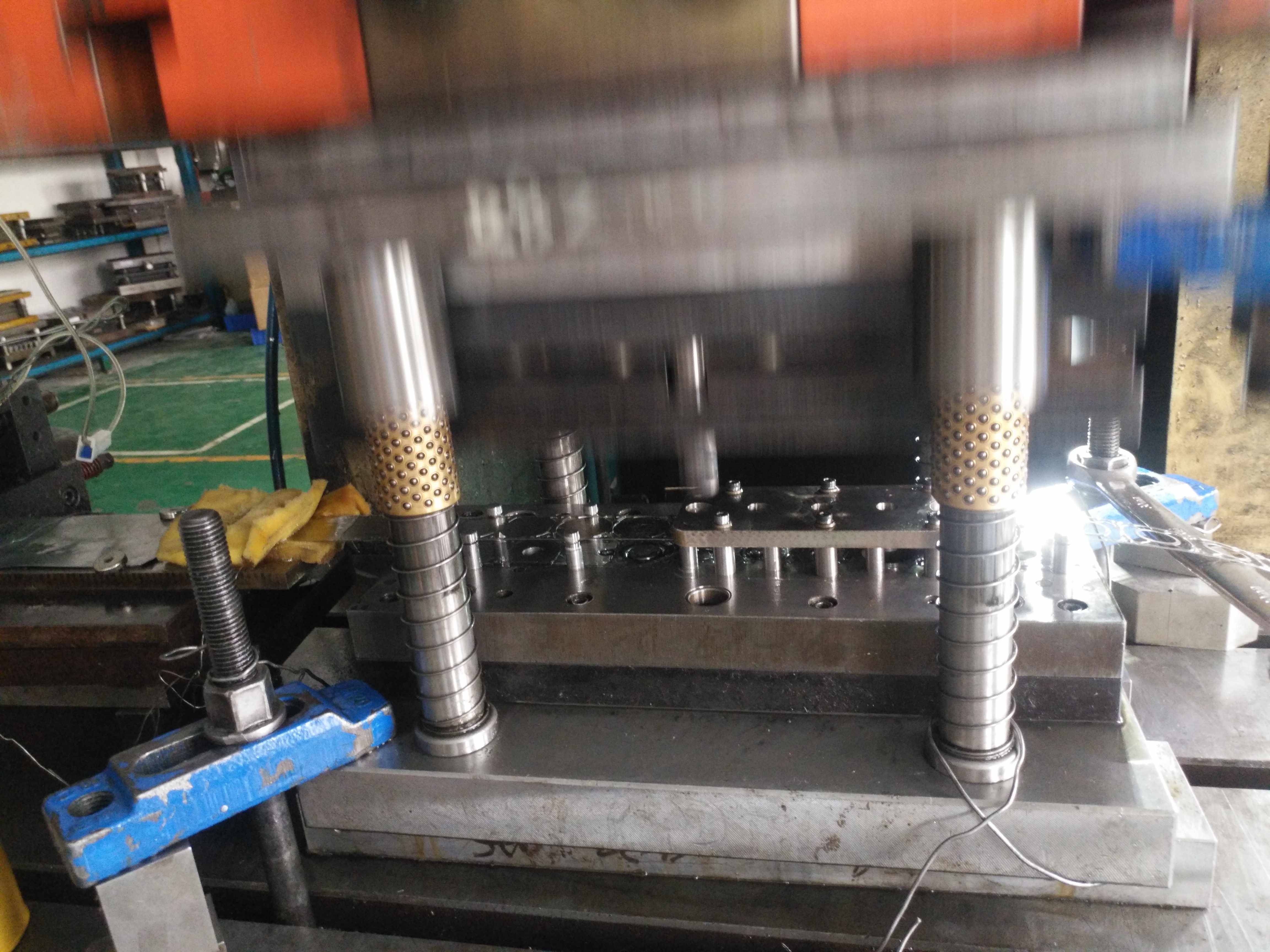

We are specialized in manufacturing deep drawing parts, can customize molds as required dimensions. the process flow is mold design →material purchase→milling/drilling→heat treatment→grinding→wire-cutting→assembly→die trial→samples confirmation.

3. Equipment:

We have own professional equipment, including high speed stamping press machines, mold process equipments, high precise measuring equipment etc.

4. Quality assurance:

Before volume production, we'll send samples to your inspection. In addition, we shall inspect each part during every processing step and 100% inspection before shipment by micrometer

5. Advantage:

1. One stop service from mold design & making to resonant bar mass production.

2. Strickly quality control

1)Technician self- check in production

2) engineer spot check in production.

3)QC inspects after mass production finished

3. Providing good service from inquiry receiving to after service

4. Reasonable and competitive price

5. we have complete equipment, relevant process we can make in house,

by this, we can control lead time, product cost and quality well

6. Small order can be acceptable.

7. OEM & ODM service support

Xinwangtai established on June 6, 2003 and located in Building A2,

Yabian Industrial Zone, Shajing Street, Bao’an District, Shenzhen

City, Guangdong Province, we are a hardware product factory

specialized in manufacturing of metal deep drawn parts, and our

main products are: 1. resonant bar of radio frequency base station;

2. perfume bottom cap; 3. earphone screen and filter screen; 4.

stainless steel sensor shell; 5. smoke alarm shell; 6. crystal

oscillator shell; 7. vibration motor shell; 8. battery shell and

battery sealing cap; and 9. intelligent capacitor metal shell. Our

products are widely applied to the fields of radio-frequency

communications, sensors, crystal oscillators, motors, lithium

motors, capacitors and intelligent dressing consumption.

With the support of hardworking and rich-experienced engineers, we

are excellent at customizing the molds and parts as you required.

Along with these, we also undertake design & development work

of press tools, fixtures & gauges and re-engineering &

prototype development.

The existing workshop of the Company covers an area of over 3,000 m2, and possesses over thirty units of precision punches such as Taiwan Mingxu 45T, 60T, 110T and 160T; a complete set of mould manufacturing and repair equipment including the numerically controlled lathe, Japan SODICK slow-feeding linear cutting machine, Japan WASINO jig grinding machine, high-precision surface grinder, CNC machining center, punch grinder and milling machine; post-treatment equipment such as high-frequency ultrasonic cleaner; and testing equipment such as tensile machine, digital hardness gauge, tool microscope, precision projector and quadratic element.

Welcome to sending us your drawing for inquiry, we'll offer our

best price in high quality.

FAQ

1 . Q:Are you a factory or trading company?

A : We are a factory, specialized in deep drawing parts

manufacturing.

2 . Q:Where is your factory located? How can I visit there?

A : Our factory is located in Shajing Baoan Shenzhen City,

Guangdong Province, China,We warmly welcome all our clients, from

home or abroad, to visit us!

3 . Q:What is the material of your molds?

A : The material are DC53,SKD11,D2,SKH-9,SKH-51 ,ASP-23, Tungsten

steel.

4 . Q: What the press your fatory have ?

A : There are 30T,60T,110T,160T, 200T press machines in

our factory.

5 . Q:What about the equipment of your factory?

A : Our factory owns a full set of Machining equipment, include

large CNC machning center,Sodic EDM machning,import EDM-HS,Radial

drilling machines,Milling machines,Grinders,three-D inspection etc.

6 . Q:How does your factory do regarding quality control?

A : Quality is priority. We always attach great importance to

quality controlling from the very begining to the very end. All the

parts, the QC measure strictly before shipment.

Why choose us?

1. Over 14 years experience specialized in deep drawing product, metal stampings.

2. Top quality with reasonable price and perfect service to provide the most cost-effective products.

3. Provide the value added service within pre-sales and after-sales

4. Accept OEM/ODM orders.

5. Wide products range including molds design & making and other stamping parts manufacture.

6. Strict quality measurement system, every product should go through many checks.