GUANGDONG RUIHUI INTELLIGENT TECHNOLOGY CO., LTD. |

|

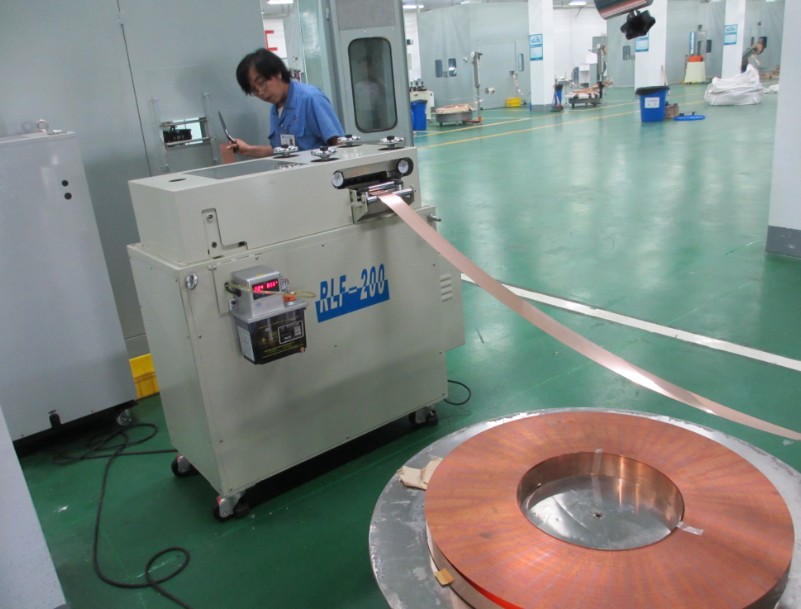

Automatic Press Machine Steel Plate Straightening Machine For Copper Material

Features:

1. suitable for straightener different metal sheets

2. equipped with Japan magnetic contactor and electronic components , minimum breakdown

3. efficient automatic material feeding equipment, a dramatic increase in productivity is achieved by lane up with auto heavy uncoiler

4. hard-chrome-plated roller , low wear, long operating life at the inport and export of HS-series use air cylinder to clamp materials , and adopts turbine compression bar adjust, it is it is more safety and Stable operation

| Model | RLF-200 | RLF-300 |

| Max.Material Width(mm) | 200 | 300 |

| Material Thickness(mm) | 0.1~1.4(200/0.1-0.6,109/1.0,69/1.4) | |

| Speed(m/min) | 5~30 | |

| Motor(HP) | 2 | |

| Inverter | Provided | |

| Work Rolls | Upper 11/Lower 11 All Drive Function | |

| Pinch Rolls | Upper 1/Lower 1 | |

| Back Up Rolls | Provided | |

| Adjustment | 4 Point Fine Micor Adjustment | |

| Loop Control | Touch Sensor | |

| Work Roll Opening | Manual Operation | |

| Drive Method | Universal joint actuation | |

Straightening performance:

| Model | RLF-200 | RLF-300 | |

| Stock Thickness(mm) | 0.1~0.4 | 200 | 300 |

| 0.5 | 200 | 262 | |

| 0.6 | 200 | 210 | |

| 0.8 | 145 | 146 | |

| 1 | 109 | 108 | |

| 1.2 | 85 | 84 | |

| 1.4 | 70 | 68 | |

1. Oiling device:An electromotive pump forces oil to the work

rolls.

This oiling device eliminates the need for

troublesome maintenance work and supports the optimal operation of

the remaining quantity of oil can be checked at a glance,and oil

can easily be added.

2. The amount of flatness-adjustment can be easily controlled

throught the operation of handles.

The amount of flatness-adjustment can be

controlled not only at the inlet and outlet sides.but also at the

back and front sides simply through the operation of handles.

3. Work rolls:Precision machining using 22 work rolls with the

thinnest diameter.

22 work rolls with the thinnest diameter [φ12mm]

on the market remove residual stress.Wide sheet metals of up to

300mm in width can be handled,which satisfies the increasingdemand

for precision components machining.

4. Caster base:A caster base with locking casters for easy

movement and fixing is included as standard equipment.

The caster base enables flexible setting of the

leveler.

5. Drive unit:Drive unit with specifications of a higher-grade

unit.

The drive unit is compact but has the

highest-level specifications such as superior electromotive

efficiency, oil-bath type gearbox, and a universal joint. The

inverter in the drive unit enables flexible speed change.

6. Detection by a lightweight cam:The cam maintains the appropriate

tension of the material and supports optimal operation.

The leveler ensures that the inverter always

operates optimally in accordance with the line speed. Smooth

acceleration and deceleration reduces loads imposed on materiales

and equipment such as the feeder. Forward and backward operations

can easily be changed simply by flicking a switch.

7. Inventive antenna type detection bar.

The ultra lightweight detection bar can be

operated with only 10g of operation force and can detect both

conductive and non-conductive thin sheet metal. Furthermore, a

unique curved shape prevents scratches on the material surface for

worriless operation.

FAQ:

Q1:What kinds of machines do you have?

Service:

1. Pre-Sales Service:We have professional designers to meet the different requirement.

Why choose us?

1st,We have a high level of technical research and development team;

2nd,We can provide the design and planning of the whole plant to

realize the turnkey project;

3rd, our philosophy: quality is the social responsibility;

4th,our products have been recognized by the market, in the major

automotive OEM, home appliance industry, hardware industry has been

applied;

5th,We have a highly effective after-sales service team and get

customer approval