Suzhou Tongda Machinery Co., Ltd. |

|

| MODEL | Units | HSII-12L | Remarks: we will customize the most suitable machinery according to your requirements |

| Max. Product volume | L | 12 | |

| Output of HDPE | kg/h | 180 | |

| Clamping force | kn | 158 | |

| Screw diametre | mm | 100 25:1 | |

| Screw heating power | kw | 21 | |

| Blow pressure | mpa | 0.6 | |

| Size of machine | m | 4.9×3.1×3.2 |

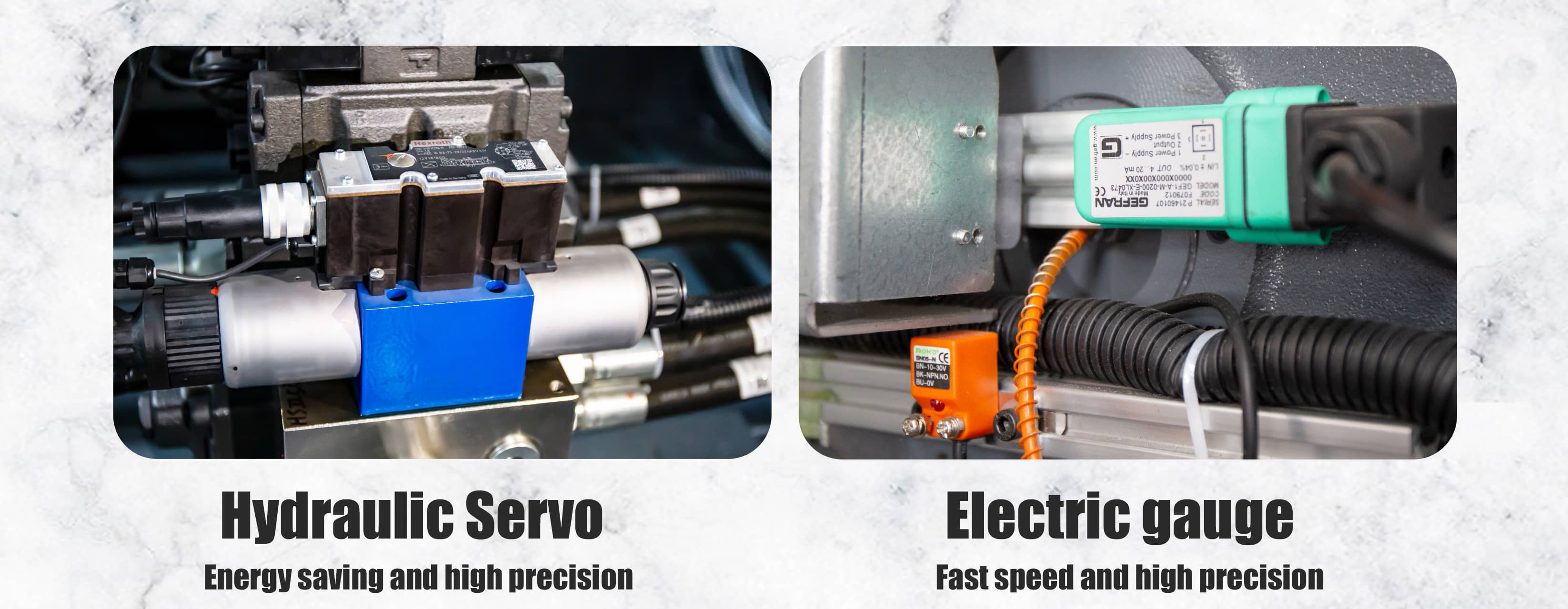

Hydraulic Servo:Energy saving and high precision

Electric gauge:Fast speed and high precision

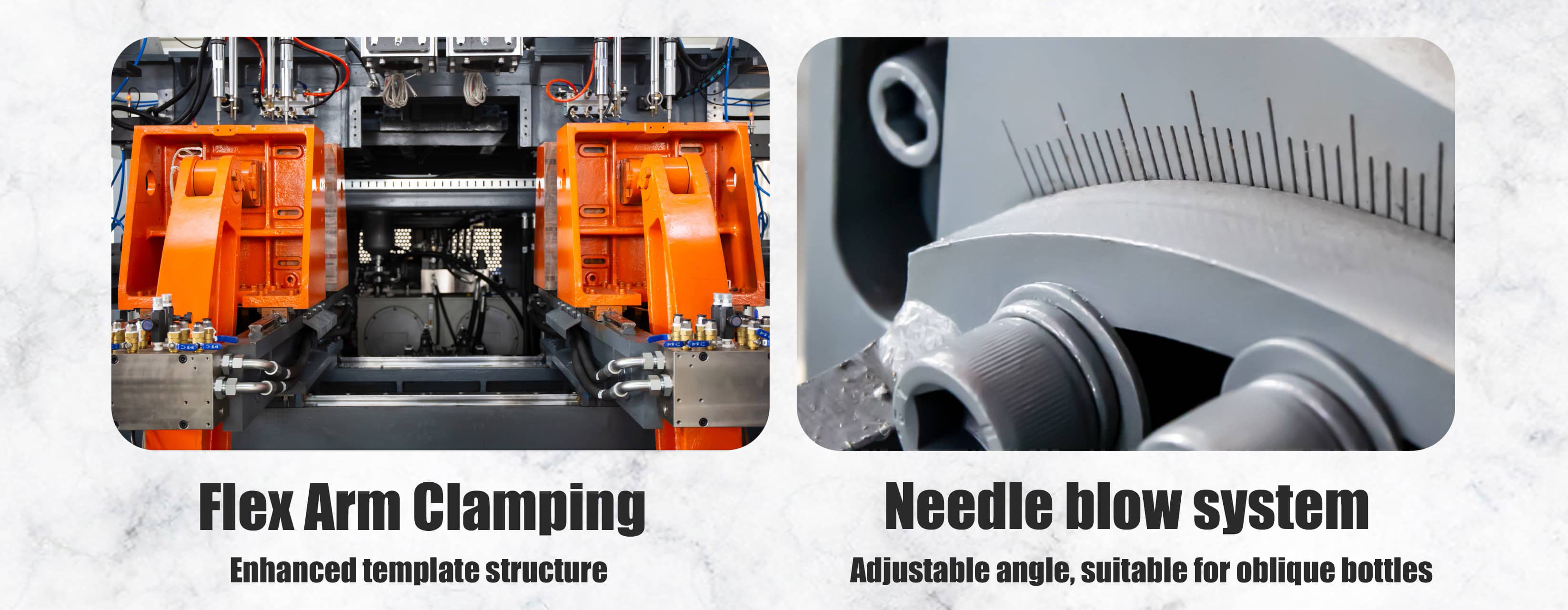

Flex Arm Clamping:Enhanced template structure

Needle blow system:Adjustable angle, suiable for oblique bottles

In the recent 20 years, Suzhou Tongda Machinery Co., Ltd. has been focusing on the research, development and product application of extrusion blow molding machines. The factory covers an area of more than 80 acres of land and has more than 350 employees.

Warmly welcome new and old customers to visit, to guide.

After-sales Service

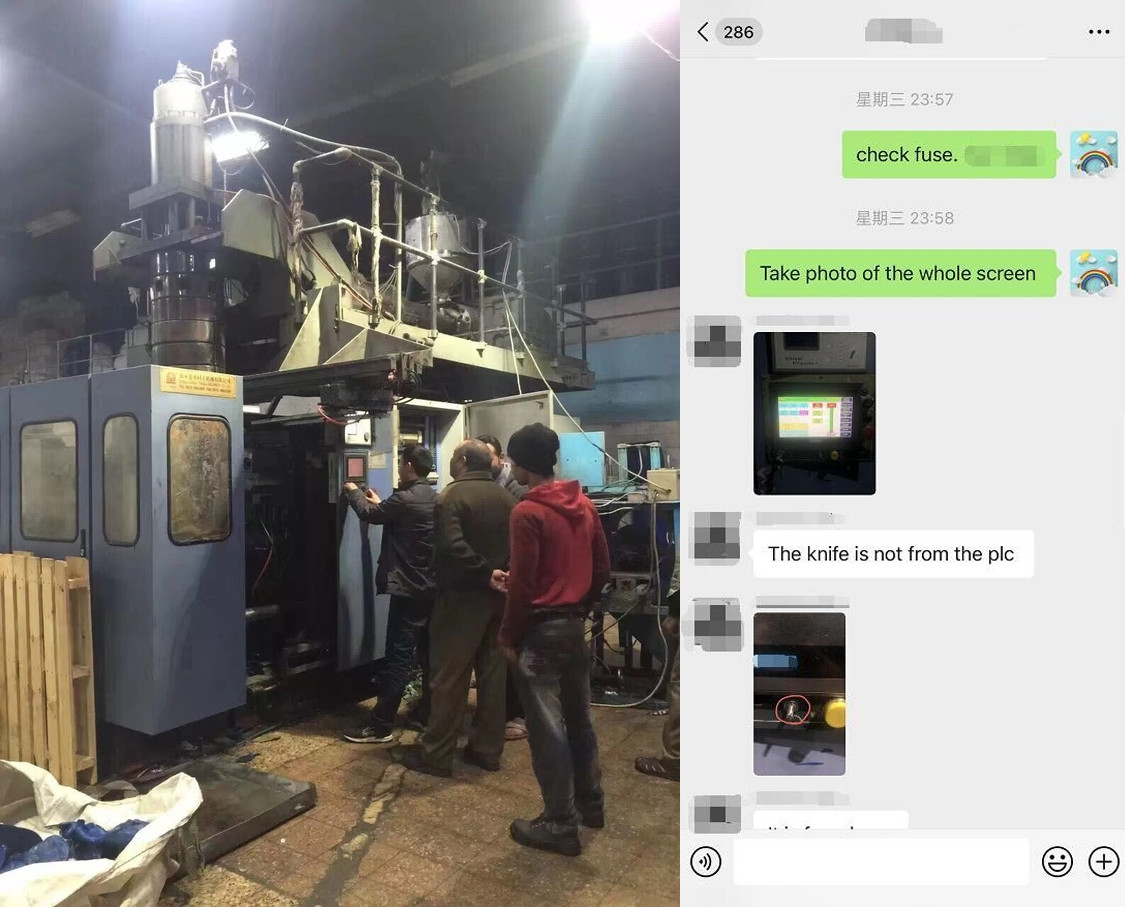

During epidemic period, our team have helped customers start up more than 250sets new Tongda machines by online service, to help customer run the machine as soon, our after sales team helped around 3 hours till the mid-night.

TONGDA sales consultant

1. We can provide comprehensive and professional Suggestions on

equipment selection.

2. Energy consumption calculation and investment income analysis

can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product

optimization Suggestions.

4. Extrusion plastic bottle blow molding machine has remote

maintenance function

Advantages of TONGDA after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of

auxiliary equipment.

5. A free 2-day training course will be provided to customers every

year.

6. Special processing equipment to produce after-sales accessories

to ensure rapid response to user needs.

Q: How big is your company?

A: our company has 400 employees and A building area of 100,000

square meters. We own land and factories.The company has a

registered capital of us $2 million and a long-term business

license since 1999.