Suzhou Tongda Machinery Co., Ltd. |

|

5L HDPE Hollow Jerry Can Blowing Machine Extrusion Fully Automatic

This is our basic series machine.It is double station.This machine is suitable for producing 50ml-20L plastic containers.Most cost effective series machine for high production capacity choice.

| MODEL | Units | HTII-5L | Remarks: we will customize the most suitable machinery according to your requirements |

| Max. Product volume | L | 5 | |

| Output of HDPE | kg/h | 85 | |

| Clamping force | kn | 70 | |

| Screw diametre | mm | 70 | |

| Screw heating power | kw | 13.2 | |

| Blow pressure | mpa | 0.6 | |

| Size of machine | m | 3.43*2.3*2.65 |

Product Details

Energy acuumulator configuration save power energy instead of using a separate oil source and motor and save space.

Automatic lubrication system, ensure the machine works more smoothly and the service life of parts longer

Company Information

We have Benchmark customers in USA-Poland-Chile-Peru-Russia-Saudi Arab-Qatar-Jordan-Iran-Egypt-Algeria-Ethiopia, etc.

After-sales services

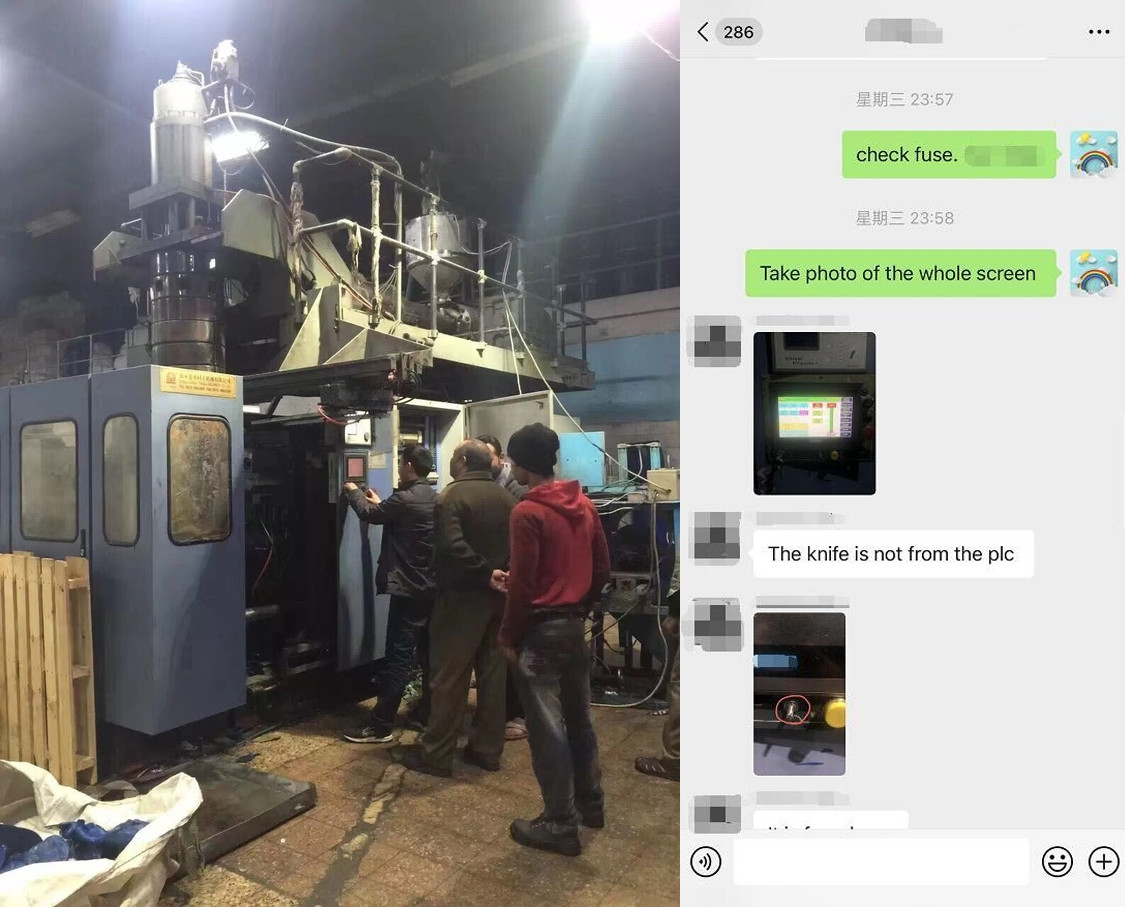

During epidemic period, our team have helped customers start up more than 250sets new Tongda machines by online service, to help customer run the machine as soon, our after sales team helped around 3 hours till the mid-night.

FAQ

TONGDA sales consultant

1. We can provide comprehensive and professional Suggestions on

equipment selection.

2. Energy consumption calculation and investment income analysis

can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product

optimization Suggestions.

4. Extrusion plastic bottle blow molding machine has remote

maintenance function

Advantages of TONGDA tech teams

1. 800 sets of customized requirements per year enable us to have

rich experience across multiple industries.

2. Customize equipment models according to customer product

characteristics.

3. Project responsibility system, closed-loop team cooperation

between the design team and the process team, adjustment of the

team, and joint creation of equipment that users are satisfied

with.

4. Engineers can study abroad or participate in technical function

training of the industry to master the latest information and

technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior

technical personnel composed of the construction team, can build

cable bridge, installation of a complete set of equipment.

Advantages of TONGDA after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of

auxiliary equipment.

5. A free 2-day training course will be provided to customers every

year.

6. Special processing equipment to produce after-sales accessories

to ensure rapid response to user needs.