Hyzont(Shanghai) Industrial Technologies Co.,Ltd. |

|

Verified Suppliers

|

|

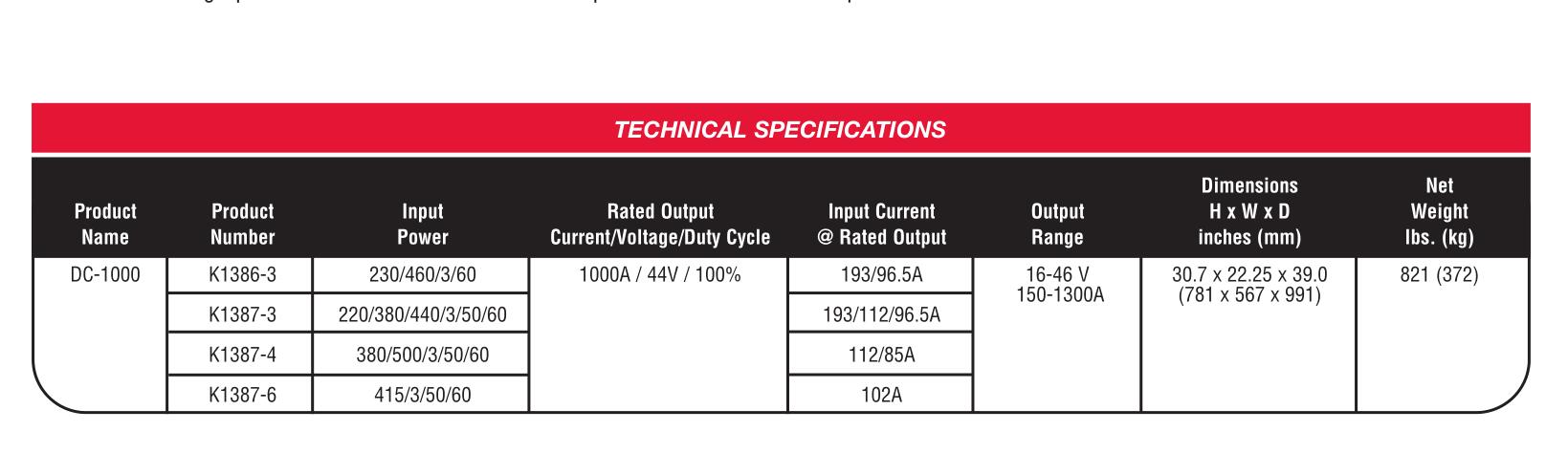

Submerged Welding Machine Lincoln Welding Machine DEALARC® DC-1000 1000A Submerged Welding

If your application requires pure welding power combined with

multi-process flexibility, then the DC-1000, with 1300 amps of

smooth DC output, is your best investment.

Designed for semiautomatic and automatic welding, the precise

control of the DC-1000 delivers superior high amperage MIG,

flux-cored, submerged arc welding and air carbon arc gouging with

up to 5/8" (15.9 mm) diameter carbons.

• Single range control for precise output control and easy

operation.

• Standard analog ammeter and analog voltmeter.

• Use the mode switch to select the desired output characteristics

for the process being used–CV Submerged Arc, CV Innershield ® ,CC

Submerged Arc.

• Power start/stop push button (NVR) switches with pilot light.

• Fuse protected 115V wire feeder auxiliary power with1000 volt-amp

capacity.

• Terminal strip and output studs for remote connections and cable.

• Low profile case allows installation of the DC-1000 under a

workbench and for stacking up to 2 machines to conserve floor

space.

• Removable side panels for easy access to internal parts.

• Line voltage compensation maintains weld consistency, even with

line voltage changes of ±10%.

• Electronic and thermostatic protection from current overload and

excessive temperatures.

• Internal components, including windings, rectifiers and circuit

boards, are coated to protect against the effects of

moisture and corrosion.

• Recessed front panel protects operating controls.

• Three-year warranty on parts and labor.

• Seven-year warranty on the power rectifier.

• Manufactured under a quality system certified to ISO 9001

requirements and ISO 14001 environmental standards.

Process