Jiaxing Dexun Co.,Ltd. |

|

Verified Suppliers

|

|

Three-point Q198 auto standard M6*14 8.8 Phosphate blackening welding screws.

Description

The basic steps of welding bolts

First, everyone needs to clean the broken ends of the bolts and the dirt on the surface, then use an electric drill to install a drill that meets the diameter requirements, and start drilling in the center of the section. Remember that the hole must be drilled thoroughly. After the hole is drilled, the small drill bit can be removed, and then replaced with a larger diameter drill bit. At this time, the drill hole needs to be enlarged and the drill hole needs to be drilled.

Secondly, take a welding rod with a diameter within the specified range, and use a medium-to-small current to perform surfacing welding from the inside to the outside in the hole of the welding bolt.

Third, the starting position of the surfacing welding must be determined according to the entire length of the welding bolt, which is usually a normal length, and then during the surfacing welding process, avoid burning through the outer wall of the bolt.

Fourth, after the surfacing is completed, it is necessary to use a hand hammer to strike the end face. In this way, the heat generated by the arc before plus the subsequent cooling effect and the vibration generated by the strike will make the bolts and the threads of the machine body In between, there was a loose phenomenon.

Fifth, carefully observe that after knocking, if there is a small amount of rust leaking from the position of the bolt fracture, then at this time, you can choose a nut that meets the requirements to cover the surfacing stigma, and complete the last step of welding the bolt. Welding combination.

Sixth, the welding tools and bolts must be kept in a clean state, otherwise it may directly affect the welding effect of the bolts.

| Product name | Three-point Q198 auto standard M6*14 8.8 Phosphate blackening welding screws |

| Material | 8.8 Grade Carbon Steel |

| Surface Treatment | Phosphate blackening |

| Color | Black |

| Feature | Durable;Preservative |

| Head Style | Round |

| Packing | Poly bag+Carton with pallet |

| Grade | 8.8 |

| Service | Customized OEM /ODM |

| Standard | DIN, DIN,GB,ISO,JIS, |

| Certification | ISO9001 |

| Process | Cold heading;Tapping |

Factory Diaplay

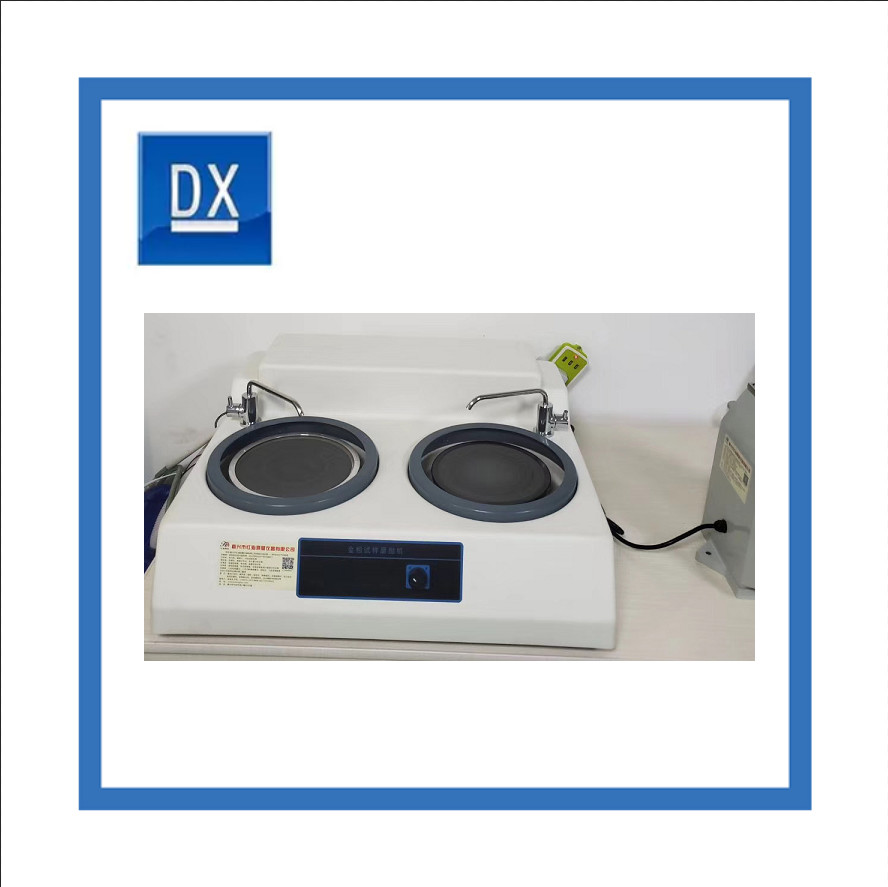

Inspection Equipments

Package Room

Q1: Can I visit your factory?

A2: Yes! Warmly welcome to visit our factory. It would be Great if

you can inform us in advance.

Q2: The quality of your products?

A2: The company has advanced production and testing equipment

.Every products will be 100% inspected by our qc department before

shipment.

Q3: How about your price?

A3: High quality products with reasonable price. Please give me a

inquire, I will quoted you a price for you refer at once.