Jiaxing Dexun Co.,Ltd. |

|

Verified Suppliers

|

|

Alloy steel Chrome plating Surface treatment Customization welding screw.

Description

Welding screw is also called energy storage screw, electric bolt welding stud, or planting welding nail, etc.

The chromium-plated layer has a very high hardness, and its hardness can vary within a wide range of 400-1200HV according to the composition of the plating solution and process conditions. The chromium-plated layer has good heat resistance. When heated below 500℃, there is no obvious change in gloss and hardness. The temperature above 500℃ starts to oxidize and discolor, and the hardness starts to decrease when the temperature exceeds 700℃. The friction coefficient of the chrome layer is small, especially the dry friction coefficient, which is the lowest among all metals. Therefore, the chrome-plated layer has good wear resistance.

The chromium plating layer has good chemical stability. It has no

effect in alkali, sulfide, nitric acid and most organic acids, but

it can be dissolved in hydrochloric acid (such as hydrochloric

acid) and hot sulfuric acid. In the visible light range, the

reflectivity of chromium is about 65%, which is between silver

(88%) and nickel (55%). Because chromium does not change color, it

can maintain its reflectivity for a long time and is better than

silver and nickel.

| Product name | Alloy steel Chrome plating Surface treatment Customization welding screw |

| Material | Alloy Steel |

| Surface Treatment | Chrom plating |

| Color | Black |

| Feature | Durable |

| Thread Type | Full Thread |

| Size | As yr drawing |

| Certificate | SGS;ROHS |

| Service | Customized OEM /ODM |

| Application | Marchinery |

| Certification | ISO9001 |

| Process | Cold heading;Tapping |

Factory Diaplay

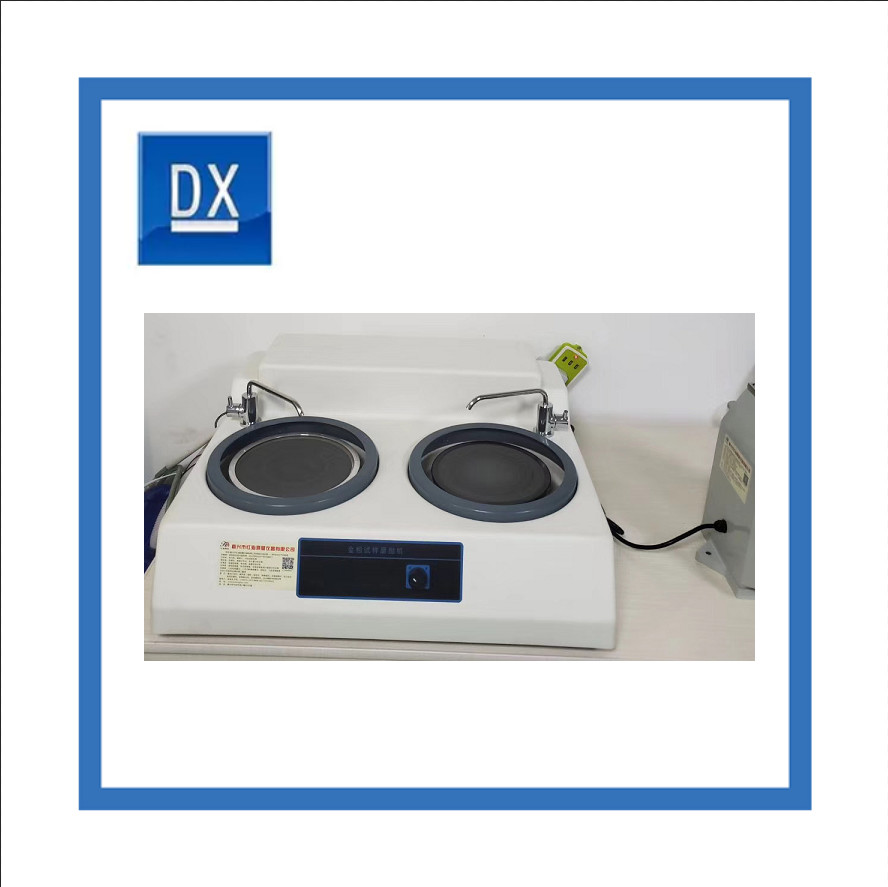

Inspection Equipments

1.How long is ur delivery time?

A:Mostly depending on ur QTY.Generally 30-45 workdays after payment

received!

2.What is ur surface treatment?

A:We can do galvanized,Yellow Zinc Plated,black and HDG and others.

3.What is ur material?

A:We can provide steel,stainless steel,carbon steel,brass and

aluminum.

4.Do u provide samples?

A:Yes! FREE SAMPLE!!!

5.Where is the port of shipment?

A:Ningbo and Shanghai.