Jiangyin Jack-Aiva Machine Co., Ltd. |

Suspended Ceiling Tile Machine

Brief Introduction- Aluminum Ceiling Tile of Lay In, Lay On and Clip In

The Aluminum Decorative Metal Ceiling is widely adopted in offices and residential buildings, because of its easiness of installation and the possibility of making changes any time after installation without infrastructure. In addition It's considered as economic and liable solution for dividing any open area with considering the fact that it is not designed for applying high loads. Our manufacturer has been in this roll forming machinery industry for over 20 years, also the lead supplier for this aluminum ceiling tile machine in china. The standard sizes of Aluminum Ceiling Tiles are 00x600 or 600x600, 600x1200. Plain or pattern can be selected according to the actual requirement. The normal Perforation Diameter are Φ0.8mm, Φ1.8mm, Φ2.3mm,Φ3.0mm etc. The most popular suspended perforated lay in aluminum ceiling tile is clip in ceiling panel 600*600.

Technology Specifications- Aluminum Ceiling Tile machine

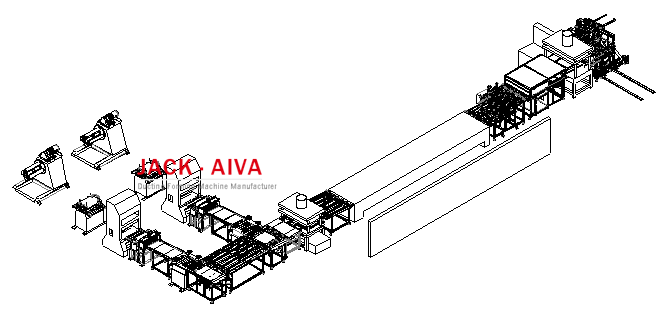

The aluminum ceiling production line is mainly used in production Lay In ceiling tile, Lay On ceiling tile and Clip In ceiling tile, applicable to a variety of cold forming and punching material. Adopt multi-PLC control, to reduce the number of hardware to guarantee the stable system. Our automatic production line replace the traditional manual control, to avoid the defects of the product precision. With this automatic suspended ceiling tile machine advantage, high precision and processing speed can be obtained, less labor cost can be achieved. The exact line component is according to client’s requirements or actual sample.

The aluminum ceiling clip in production line for 600x600mm is consisted of de-coiler, material feeding device and leveling device, holes punching device, corner cutting device, servo control system, ceiling flat sheet cutting device, run-out table, hydraulic station and PLC control system, etc.

The most advanced aluminum ceiling tile production line in the present Chinese market

Line Technology Flow

De-coiler--1sets leveling 1st -- position holes punching --- row holes punching --- Servo control feeding ----Flat sheet Cutting -- ---- 2nd leveling----corner cutting --- feeding belt ---- Cantilever type mechanical arm ---- edge bending & forming ---feeding belt --- completed products

Roll Forming Machine Main parameters- Integrated grid ceiling

| Profile type | Aluminum Ceiling Tile of Lay In, Lay On and Clip In |

| Aluminum tile sizes | 600mm*600mm,600mm*1200mm |

| Perforation holes Size | Φ 1.5mm/1.8mm/2.3mm/2.5mm/3.0mm |

| De-coiler | 5T,380V,2.2KW,50HZ |

| Leveling machine | 2.2kw ,380V, 5pcs level rollers |

| Servo feeder | high precision ,tolerance is (±0.2mm). |

| Mold type | punching mold, cutting mold |

| Gantry punch | 120T,Motor:15KW,votage:380V |

| Product capacity | 7-8 PCS / min |

Relative information for Ceiling clip in production line

We have the full ability to design all kinds of aluminum ceilings production machine according to client ceiling panel profile drawing or sample and the necessary information.

Typical Clip in ceiling specification

1. 600*600mm, 300*300mm, 300*600mm, 300*1200mm, 600*1200mm

2. Thickness: 0.5mm~1.0mm.

3. Edge: 18mm or 20mm.

4. Style: Panel or perforated (Dia: 1.8mm, 2.0mm, 2.2mm).

Ceiling clip in Moulds

The moulds is the most important part in this line, the normal steps for processing square metal clip in ceiling is including cutting corners, forming and bending, punching holes. When to design the diameter of 0.6mm-100mm aperture metal ceilings punching die, the die adopts CR12 or material CR12MOV as raw material. Heat treated to HRC58-60 degrees. The normal holes diameter is as following, Φ1.8, Φ2.0, Φ2.3, Φ2.5, Φ3.0, etc. The integrated ceiling mold is designed according to customer requirements. Pls contact with us for the further details!

Application - Aluminum Suspended Ceiling Tile

The Clip in square ceiling is widest applicable among all type of ceiling with its outstanding advantages, Ceiling tile of Lay In, Lay On and Clip In. This suspended ceiling system is mainly used in project for big area with soundproof requirements, such as hotels, stores, office building, hospitals, railway stations, metro stations and so on.

The following installation for Clip-In Plain / Clip-In Perforated ceiling tile as reference.

The ceiling tile production machine can be custom prepared according to clients’ request. You are welcome to contact with us for the further details.