SiChuan Liangchuan Mechanical Equipment Co.,Ltd |

|

Verified Suppliers

|

|

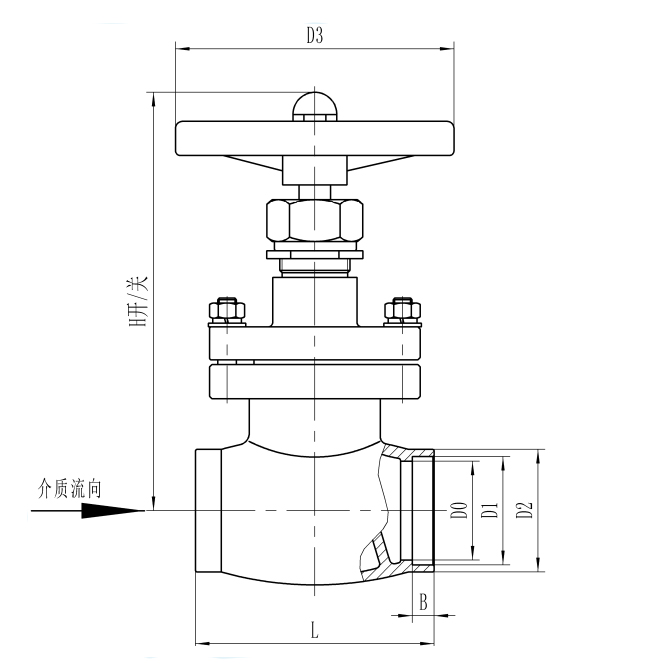

Stainless Steel DN15 PN40 Cryogenic Socket Weld Globe Valve for LNG LO2 LN2

Product Description

Cryogenic valves are very similar to conventional valves, with the exception of materials and features such as an extended stem. These extended stems allow handles or actuators to be at an ambient temperature.

Name: Short stem globe valve | |

Main technical parameters: | Nominal diameter: DN10-250mm |

Nominal Pressure: PN4.0MPa | |

Applicable medium: O2, N2, Ar, LNG | |

Applicable temperature: -80℃~+80℃ | |

Connecting format: | |

Material: | Body: CF8 |

Bonnet: 06Cr19NI10 | |

Stem: 06Cr19NI10 | |

Packing: PTFE | |

Disc face ring:PCTFE | |

Drawing

Notes When Use

1 . It should ensure that the pipe is blown clean before

installation.

2 . When installing, make sure that the flow direction indicated by the arrow on the valve body should be consistent with the flow direction of the fluid.

3 . This valve has been degreased. Store and keep clean when installing.

4 . After the pipeline construction is completed, all the valves on the pipeline should be opened, and the residue in the pipeline should be thoroughly and thoroughly kept to ensure that the pipeline system is clean and free of debris.

5 . The installation system diagram with the oil-free requirements should be degreased.

6 . Slowly open and close during use.

7 . If the precision parts such as the valve disc, valve seat and valve stem are worn or damaged, it must be repaired and replaced in time.

8 . For parts such as gaskets and sealing materials, replace them with new ones each time.