Liquid nitrogen generator 12000/30 Nm3/h KDN-12000/30Y

Specifications:

Standard Product List for the Liquid Nitrogen Generator KDN

10000~13000 series

MODEL CONTENTS | KDN-10700/33Y | KDN-11800/400Y | KDN-12600 | KDN12800/200Y |

GAN/LIN flow | Nm3/h | 10700/33 | 11800/400 | 12600 | 12800/200L/h |

GAN/LIN purity | ppm | 10ppm(O2) | 2ppm(O2) | 1ppm(O2) | 1000ppm(O2) |

GAN/LIN pressure | MPa | 0.84 | 0.58 | 0.8 | 0.8 |

Subcooled | K | 286.15/80.5 | 293.15/103.5 | 286 | 286.15/102.15 |

Typical Product: KDN-12000/30Y

Liquid nitrogen generator

Output, purity and pressure

| Flow (Nm3/h) | Purity | Pressure MPa(G) | Subcooled (K) |

GAN | 12000 | ≤10ppm(O2) | 0.01 | 286.15 |

LN | 30 | ≤10ppm(O2) | 0.12 | 97.15 |

Description:

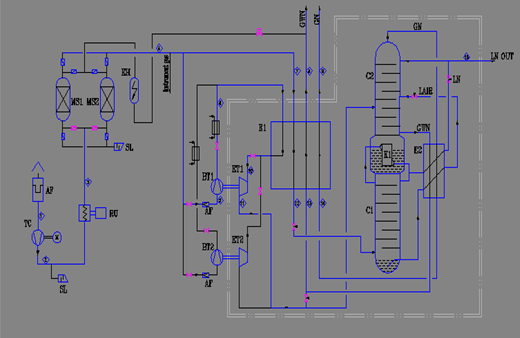

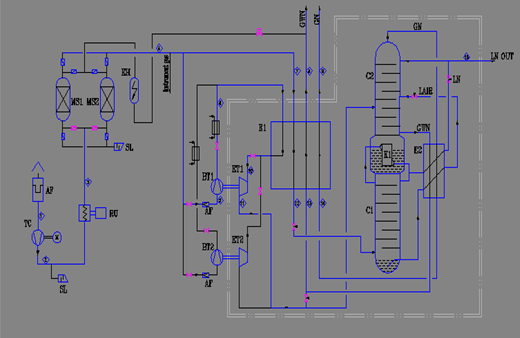

The proposed plant employs a double columns process in which air is

purified by molecular sieve and refrigeration with drag flow

expansion.

- Following the preliminary process, the air is cooled to be reached

saturated condition.

- The air out of adsorber will be divided into three steams: one

steam will be withdrawn as instrument air, the second steam

goes into the main heat exchanger E1 directly to be cooled, and

then part of it will reach saturation temperature after going out

of E1, and then goes to the bottom of lower column C1 to follow the

rectification; the third steam goes to the main heat exchanger

after being boosted and cooled in theboosting end of expander , and

then it is withdrawn from the middle of heat exchanger to the

expander for expansion refrigeration, and part expanded air will be

fed to the upper column to follow the rectification, and the rest

will go out of cold box after it reflows to the main heat exchanger

and be warmed.

- The air will be separated into pure liquid nitrogen and liquid air

after being rectified in the lower column. The liquid air in the

bottom of lower column goes into the lower part of upper column

through subcooling throttling, and then flows into the condensation

evaporator as the cold source of condensation rising nitrogen by

the column plate.

- Regarding the liquid nitrogen in the top of lower column, part of

it will be withdrawn and go to the top of upper column to follow

the rectification, and the rest will be withdrawn as product.

- The oxygen enrich gas in the bottom of upper column will be

withdrawn and go into the subcooler and main heat exchanger to be

rewarmed, and then goes out of cold box to be as the regeneration

gas of molecular sieve adsorber.

- The nitrogen in the top of upper column will be withdrawn as the

product, and goes out of cold box after being rewarmed in the

subcooler and main heat exchanger, and then fed to the piping net

after being boosted to the pressure required by the user.

Applications:

- Machinery & Construction

- Spectroscope Gas

- Inert Gas

- Carrier Gas

- Filling Gas

- Lifting Gas

Competitive Advantage:

- Our company owns the most advanced technological level

- Our company is the biggest air separation plant design and

manufacture base

- Mature project engineering supervision

- High reliability

- No gas loss and high yield