Hangzhou Hangyang Cryogenic Liquefaction Equipment Co., Ltd |

|

Liquefaction Plant 4500/4500Nm3/h YPON-4500/4500 Liquefaction Equipment

Specifications:

Standard Product of Liquefcation Plant YPON Series

MODEL CONTENTS | YPON-400TPD | YPON-440-1000 | YPON-50TPD | YPON-8750-9000 | |

LOX/LN flow | Nm3/h | 11700/13350 | 1100/1250 | 1500/1700 | 8750/9000 |

LOX/LN purity | ppm | Same as the feed air | Same as the feed air | Same as the feed air | Same as the feed air |

LOX/LN pressure | MPa(G) | ~0.83/0.9 | ~0.2/0.2 | ~02/0.2 | ~1.58/1.7 |

LOX/LN Subcooled | K | 28.4/23 | 88.5/84 | 3/3 | 5/13 |

Typical Product:YPON-4500/4500 Liquefaction Plant

Output, purity and pressure

| Flow (Nm3/h) | Purity | Pressure MPa(G) | Subcooled (K) |

LOX/LN | 4500/4500 | Same as the feed air | 0.2/0.2 | 7/5 |

Description:

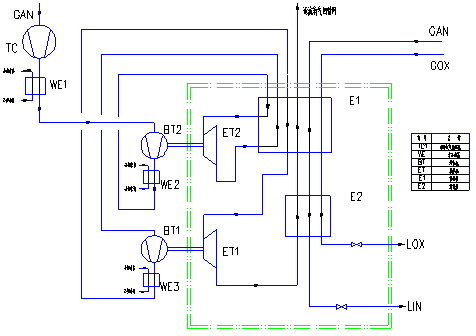

When under LOX operating condition, the circulating nitrogen is compressed to 2.5MPa(G) through nitrogen compressor, after that it flows into the boosting end of high temperature expander where the pressure is raised to 3.527MPa(G), and then it exchange heat with the refluxed low pressure circulating nitrogen. When the temperature is to 207K, the gas is withdrawn from heat exchanger E1 and flows to high temperature expander to be expanded to 0.978MPa(G), and returns to heat exchanger E1 as refluxed gas, and goes out of cold box after rewarmed. The nitrogen coming from high temperature expander and being rewarmed in the heat exchanger flows into the boosting end of low temperature expander to be boosted to 1.517MPa(G), and then it flows into the heat exchanger E1 in the liquefier cold box to exchange heat with the refluxed low pressure circulating nitrogen. When the temperature is reduced to 145K, it is extracted from heat exchanger E1, and flows into the low temperature expander to be expanded to 0.021MPa(G), after which it returns back to the liquefier E2 and heat exchanger E1 as refluxed gas to cool the drag flow circulating nitrogen and liquefy feed gaseous oxygen. And then it is rewamed and goes out of cold box, and flows into turbo compressor or pipelines to start the next recycle. The liquid oxygen in the liquefier E2 is throttled to 0.2MPa(G), and then flows to the storage tank as product.

When under LIN operating condition, the circulating nitrogen is compressed through nitrogen compressor, after that it flows into the boosting end of high temperature expander where the pressure is raised to 3.527MPa(G), and then it exchange heat with the refluxed low pressure circulating nitrogen. When the temperature is to 210K, the gas is withdrawn from heat exchanger E1 and flows to high temperature expander to be expanded, and then returns to heat exchanger E1 as refluxed gas, and goes out of cold box after rewarmed. The rewarmed nitrogen is boosted to 1.489MPa(G) in the boosting end of low temperature expander, and then it flows into the heat exchanger E1 in the liquefier cold box to exchange heat with the refluxed low pressure circulating nitrogen. When the temperature is reduced to 140K, it is extracted from heat exchanger E1, and flows into the low temperature expander to be expanded to 0.021MPa(G), after which it returns back to the liquefier E2 and heat exchanger E1 as refluxed gas to cool the drag flow circulating nitrogen and liquefy feed gaseous nitrogen. And then it is rewamed and goes out of cold box, and flows into turbo compressor or pipelines to start the next recycle. The liquid nitrogen in the liquefier E2 is throttled to 0.2MPa(G), and then flows to the storage tank as product.

Applications:

1. Depth refrigerant

2. Pharmaceutical and biotechnology

3. Source of energy

4. Health care

5. Aerospace Science And Technology

6. Petroleum refining

Competitive Advantage:

1. The process employed by this liquefaction plant is an advanced and technologically experienced process to ensure reliable running, convenience operation, safety and low consumption.

2. In design of the structure of air cooling column, the reliable measures for prevention of liquid overflow are taken.

3. High reliability.

4. Low power consumption.

5. Low Working Pressure

6. All gas and liquid plants are optimized to meet customer-specific site requirements

7. Engineers available to service machinery overseas