Guangzhou Jingyijin Machinery Equipment Co., Ltd |

|

Verified Suppliers

|

|

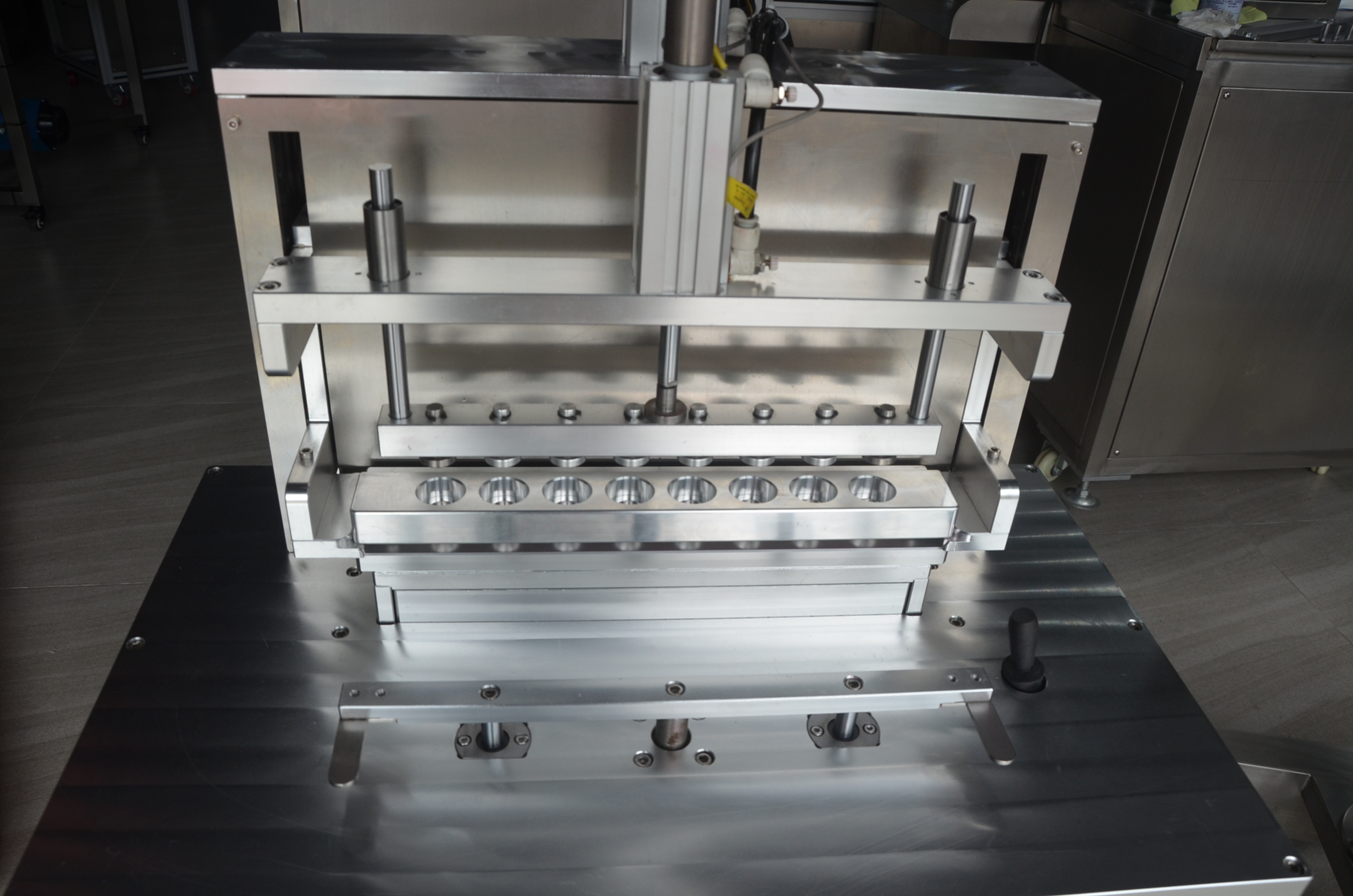

Lipstick Production Line Full - automatic Tube Spinning Machine 2 -

5 Seconds / Module

Description:

1.This machine is suitable for high quality lipstick to demould.

2.Adopt advanced automation technology (man-machine interface, PLC program control,), segment release, release parameters are set by man-machine interface, simplify the system operation procedures, the overall performance is more stable.

3.It can be used with conventional lipstick filling machine, can remove 8 mold at the same time, the mold speed is fast, the machine automatically demould, reduce defective products, more stable and faster.

Quick Details:

lipstick release machine, also known as a lipstick filling machine or lipstick mold demolder, is a specialized piece of equipment used in the manufacturing process of lipsticks. It is designed to efficiently and accurately release the finished lipsticks from their molds, ensuring a smooth and consistent production workflow.

Here's an overview of how a typical lipstick release machine works:

Mold Alignment: The lipstick molds, which are usually made of metal, are aligned and securely mounted onto the machine. Each mold contains multiple cavities that shape the lipstick bullets.

Heating and Cooling: Before the release process, the molds may go through a heating stage to ensure the lipstick formulation is properly melted and filled into the cavities. Once filled, the molds are cooled to solidify the lipstick.

Release Mechanism: The release machine employs various mechanisms to release the lipsticks from their molds. This may include pneumatic or hydraulic systems, mechanical actuators, or other mechanisms that provide controlled force and movement.

Ejection: The machine applies the necessary force or movement to eject the lipsticks from the molds. The released lipsticks are usually collected in trays or containers for further processing or packaging.

Quality Control: During the release process, quality control measures may be implemented to check for any defects or inconsistencies in the lipsticks. This may involve visual inspection, weight measurement, or other quality criteria to ensure the final products meet the desired standards.

Specification:

| source | 220V/50H z |

| power | 100W |

| Appearance size | 680*500*1400mm |

| Mold frame size | 370*42*75mm |

| Number of die-off | 8 Head / mold |

| machine weight | 80KG |

Advantages:

We have a high-quality team that can provide professional services for our customers.

Deatailed Drawing: