Guangzhou Jingyijin Machinery Equipment Co., Ltd |

|

Verified Suppliers

|

|

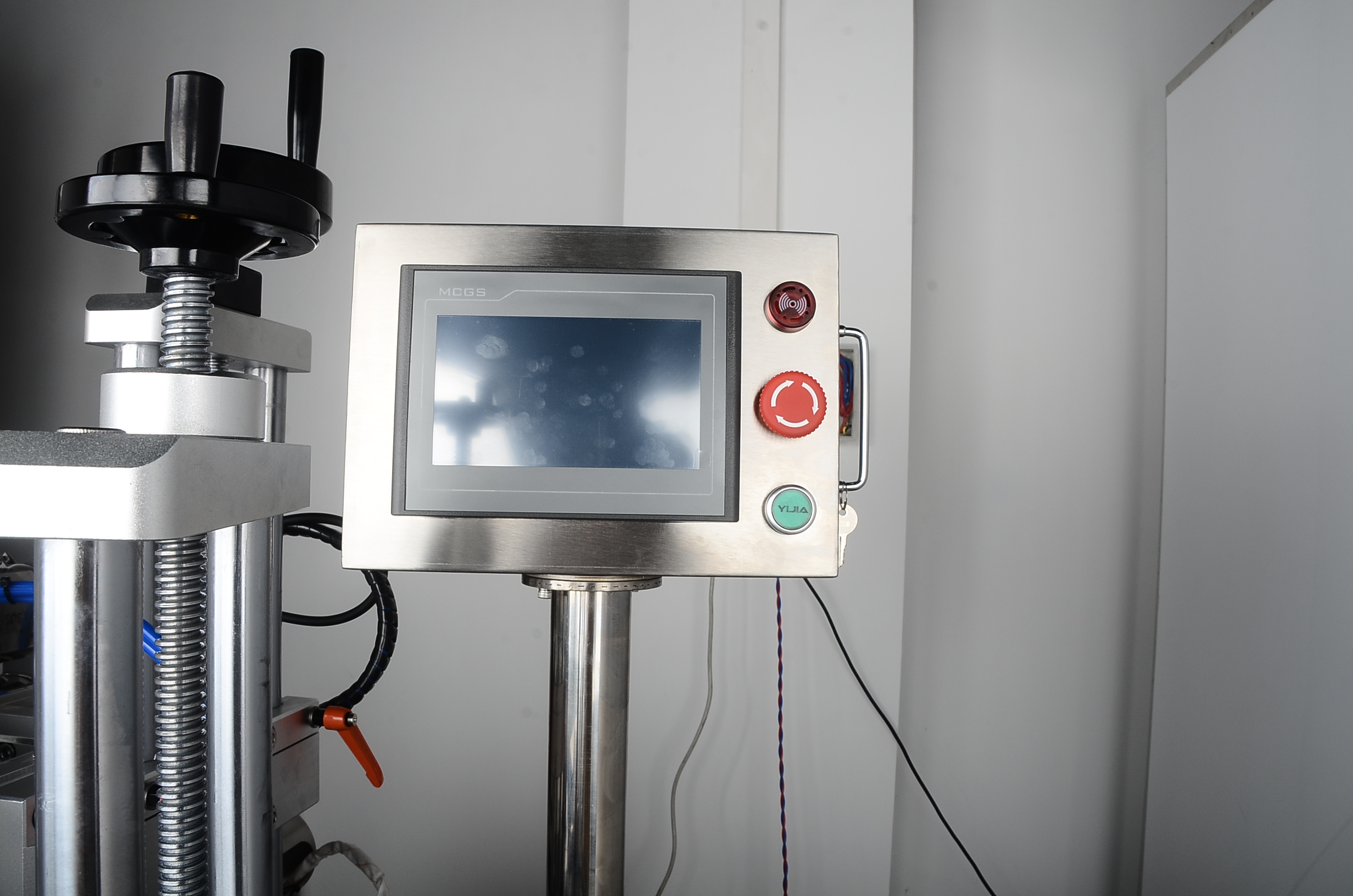

Customized Automatic Production Line Double Head Hose Fiflling And

Sealing Machine

Description:

Automatic hose filling tail sealing machine product overview: this product is suitable for medicine, food, cosmetics, chemical industry and other industries of plastic pipe, aluminum plastic composite pipe filling tail sealing. All kinds of paste, paste, viscosity fluid and other materials can be smoothly and accurately injected into the hose, and complete the pipe hot air heating, tail sealing, batch number, production date, etc.

Quick Details:

1. the machine structure is compact, can be connected to the automatic pipe, automatic feeding

2. the machine automatic operating system to complete the pipe, bid recognition, filling, hot solution, tail sealing, coding, finishing, the finished product process.

3. by the pneumatic way to complete the pipe supply, the action is accurate and reliable.

4. The rotary hose mold is equipped with the electric eye control hose center positioning device, and the induction device completes the automatic positioning.

5. the adjustment and disassembly is simple, especially suitable for the production of a variety of specifications of caliber hose users, the adjustment is convenient and quick.

6. intelligent temperature control and cooling system, make the operation simple, reliable tail sealing.

7. ultrasonic hot melting mode, according to the time control of hot melting effect, more advanced and more simple.

8. The machine speed can be controlled and adjusted by the frequency converter.

9. each station is set with the digital display screw adjustment height more intuitive and convenient.

9. The hose filling volume can be adjusted by the adjusting handwheel, which is convenient and quick.

11. equipped with a safety device, open the door and stop, no tube without filling, overload protection.

Specification:

| Filling range | 1~10ml, 10-120ml, 20-200ml |

| Filling speed | 30-60 pcs/min |

| diameter tube | 10-60mm |

| Length tube | 60-270mm |

| voltage | 380v 50/60HZ |

| air supply | 6-8MPa |

| size | 2016*960*1860mm |

| weight | 850kg |

Advantages:

We have a high-quality team that can provide professional services for our customers.

Detailed drawing: