HEBEI SOOME PACKAGING MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

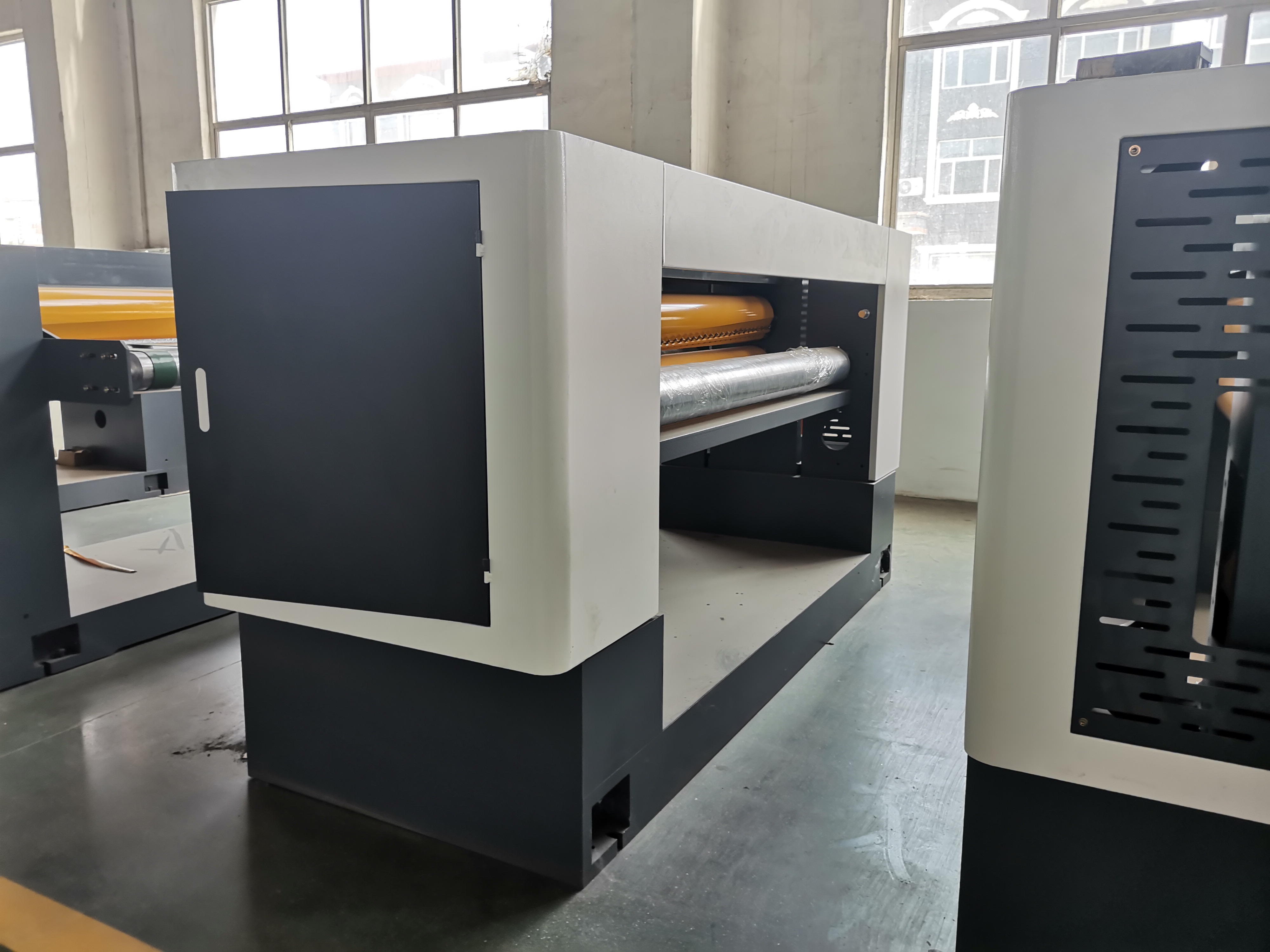

Machine intruction:

1. Designed speed:150m/min

2. Effective width: 1400mm-2200mm

3. Cutting length from 500mm up to 9999mm.

4.Cutting tolerance:stable speed ±1mm

5. Autocyc oil pump lubricationthe transmitting unit.

6. Computer-monitored tracking of production lines,assuring

simultaneous pace.

7. Computer memory of many orders. Screen display the production

information. outputting any one of orders according to finished

ones or based on actual needs.

8. Precise adjustable seamless gear assuring good mesh.

Technical specification:

| Max. Speed | 150,200,250m/min |

| Effective width | 1800,2200,2500mm |

| Cutting precision | ±1mm |

| Cutting length | 500~9999mm |

Features:

1. Cutting length:500mm-9999mm.

2. Cutting precision:±1mm.

3. Uses the independent oil pump and the filter coordinates two groups of copper tubes to distribute in various gears position for the oil,the lubrication and cooling.

4. Helical knife structure,type sawtooth knife,decrease cutting obstruction,low noise.

5. Balance treatment:high quality alloy steel for blade shaft,which helps to keep it good stability.

6. Sun-shape wheels press cardboard in the front and the rear conveyer.The transporting is stable and with even pressure,which avoid jam caused or broken cardboard.

7. This type of Cut-off just consume the one of third energy compare with the common cutter with its especial structure,economize above 70% energy to get more money.

8. Exact and adjustable on gap gear assure knife-edge joggle exactly.running balanceable.

9. Computer system to keep order. Man-machine conversation system NC. automatic adjust cutting speed by cardboard specification and maching.

10. The screen display various production message.Can consult,modification,superaddition and cancel order during running machine.

Touch-screen monitor:

Standard 5.7″ touch-screen monitor and friendly HMI on operator console is used for on-site operating.

Superior working conditions

Individual sealed control cabinet; equipped with industrial air-conditioning system; Dust-free, constant temperature and humidity working conditions ensures longer life-span of electrical components.

Stability and reliability:

High-quality raw materials, strict heat treatment, high-precision mechanical processing, ensures stable operation of equipment on the long run.

Use of international branded electrical, pneumatic components, standard parts, ensures high reliability and long service life.

High automation

High-automatic running and control, improve the efficiency, save labors, and reduce labor intensity