HRB Pack Group Co., Ltd |

|

Automatic 5 Colors Flexo Printer Slotter Die Cutter High Definition

For Carton Box

HRB 1224 VACUUM TRANSFER HIGH DEFINITION PRINTING SLOTTING | |

| LEAD EDGE FEEDER | 1 |

| PRINTER/COATING (5+1) | 5+1 |

| DRY | 3 |

| SLOTTER | 1 |

| DIE CUTTER | 1 |

| GLUER LINE | 1 |

| Model | 920 | 1224 |

| Wall board thickness | 60mm | 60mm |

| Max Machine Speed(pcs/min) | 300 | 300 |

| Economic Working Speed(pcs/min) | 250 | 250 |

| Max. Feeding Size(m/m) | 900 x 2000 | 1200x2400 |

| Min. Feeding Size(mm) | 350x600 | 400x650 |

| Skip- feeding Size(mm) | 1200x 2000 | 1400x 2400 |

| Standard Plate Thickness(m/m) | 3.9 | 3.9 |

| Min. slotter distance POSITIVE | 130X130X130X130 | 150X150X150X150 |

| Min. slotter distance NEGATIVE | 230X65X230X65 | 250X75X250X75 |

| Max slotter depth(m/m) | 300 | 300 |

| Print precision(m/m) | ±0.3 | ±0.3 |

| Slot precision(m/m) | ±1.0 | ±1.0 |

| Die cut precision(m/m) | ±1.0 | ±1.0 |

| Suitable Cardboard Thickness(m/m) | 2-11 | 2-11 |

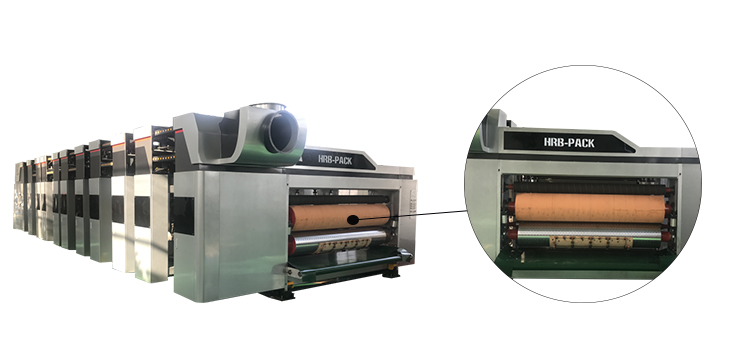

1.Lead feeder with wheels feeding system, lead feeding can adjust

cardboard length

according to cardboard specification.

2.Copy sun automation lead edge feeder with strong vacuum transfer

for precise and stable feeding;(made from guangdong province)

3.Frequency conversion adjustment vacuum negative pressure value,

can adopt to

different cardboard specification and curved cardboard.

4.Feeding roll is made of two-layer rubber,inner layer is soft and

outer

layer is hard,this makes inner layer more flexible and surface more

wear-resistant,and reduce the flute damage of the cardboard;

5.Dust remove system with brush and segmented vacuum sheets

cleaner;Self-locked system adopts for adjusting feeding rolls

gap,motorized and PLC control of feeder side guides;

6.Motorized backstop forward /backward and up/down position for

easy and quick

adjustment;

7.Five rows brush to strengthen the force of negative pressure fan

dust removal device, pipe concentrated dust collection.

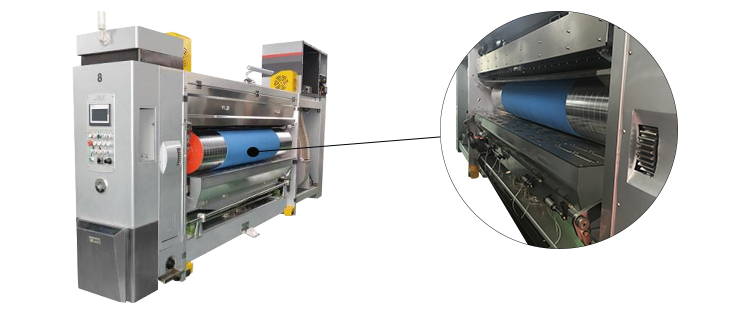

1.Pneumatic clutch is adopted on the anilox roll to:Make the roll

run at the same speed as the main motor when the unit is

printing;Make the roll stop when the unit is not printing;Reduce

the possibility of damage to the rubber roll and the anilox roll

for inproper operation;Allow units which are not in use to be

washed up while running.

2.Printing register is digitally controlled by motor and PLC

3.Transverse register is also digital controlled by motor and PLC

±10mm

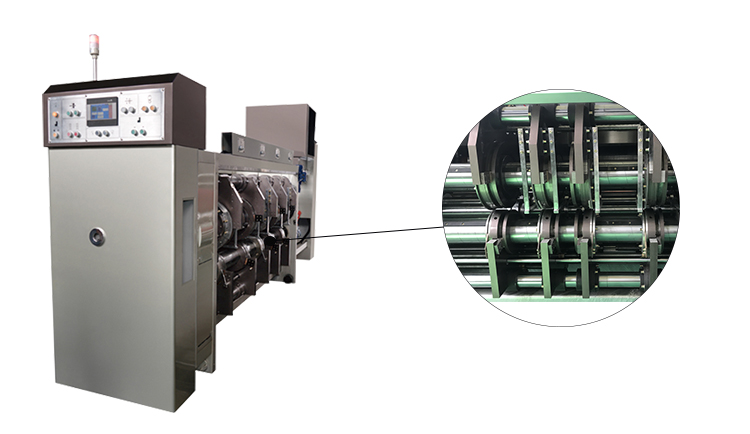

1.Vacuum adsorption ceramic wheels transfer, more rows ceramic

wheels dislocation array to strengthen cardboard transmission

stability.

2.The bellows damper can adjust by automatic according to the

cardboard size.

3.Drying system with imported PLC program automatic controlling,

man-machine dialog control and display.

4.Automatic temperature control, fault alarm protection, automatic

detection alarm, fault status display.

5.Drying system with the host control starting and closing double

protection, completely solve the cardboard directly irradiation

time heat and burning this question when the

machine stop.

1.Single shaft five blades slotting ,an internal gear adjusts the

height of the carton box and prevents the lubricating oil from

spilling or leaking onto the cardboard.

2.The first pre-creasing,the cardboard not be damaged after

prepressing.

3.Upper creasing roll covered by anvil ring,so cardboard is not

damaged easily.

4.Slotting bosses move along liner lead rails and are driven by

lead screws for flexible and precise movement.

5.Upper boss and lower boss are coupled to keep the two knives

aligned while moving,which is helpful to prolong service life.

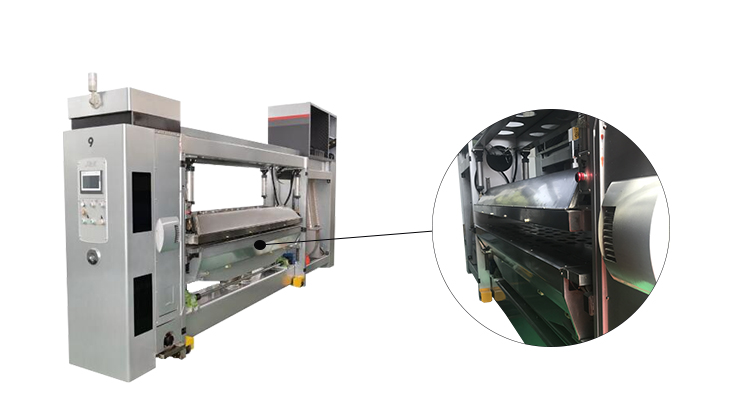

1.With separate servo motor.

2.Side to side oscillation of anvil drum(45mm)

3.The die drum’s transverse movement can prolong the service life

of anvil cover.

4.Die-cutting register is digitally controlled by motor and PLC

5.The die-cut cylinder lateral register is digitally controlled by

motor and PLC,rang about±10mm.

6.Motorized caliper adjustment between anvil roll and die drum.

7.Auto speed compensation system controlled by the independent

motor can achieve the superb die accuracy.

8.Anvil rubber roller speed compensation adopted independent motor

for driving to control the rubber roller speed,the compensation

scope is ±3mm.

9.Anvil trimmer to keep surface of the anvil covers flat and

smooth.