Cangzhou Gerun Machinery Co.,Ltd |

|

Verified Suppliers

|

|

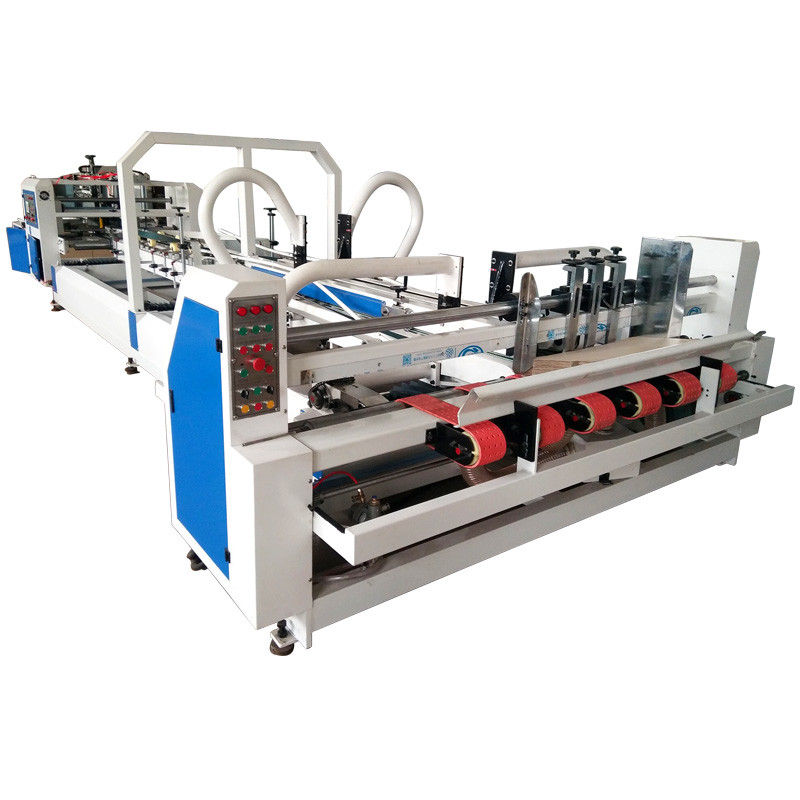

Automatic Corrugated Carton Box Auto Folding Sealing Stitching Machines

| Introduction |

Machine Briefing:

1, Suit for A, B, C, AB Flute and 3 layer, 5 layer corrugated carton paste and stitch.

2, Stitching pitch range:40-500mm

3, Stitching angle:45 degree

4, Adjustable single or double stitch,in compliant with Chinese standard 17(2.0*0.7mm)or 18(1.81*0.71mm)size nail.

Main Features:

1, Fast folding

2, 8 volume adjustable vacuum feeding belts ensures accurate feeding.

3, Three times re-creasing and folding knife get a more accurate folding.

4, Good control on fish tail phenomenon to decrease the waste

5, Machine has sheet separation and registration unit, fast order change and neat folding and gluing.

6, Using intelligent wire feeding system with less wire wheel wearing.

7, PLC, HMI and main Servo motor makes the operation of the machine simple and stable.

| Parameters |

| Model | SCS- 2400 | SCS- 2600 |

| Max. feeding paperboard size (mm) | 1200*2400 | 1200*2600 |

| Min. feeding paperboard size (mm) | 300*900 | 300*900 |

| Power required | 12 kw 380V 3phase 50HZ | 12 kw 380V 3phase 50HZ |

| Paperboard thickness | 3 or 5 layer cardboard | 3 or 5 layer cardboard |

| Control way | PLC touch screen | PLC touch screen |

| Machine weight | 6.0tons | 7.0 tons |

| Dimensions | L11000 X W3000 X H1600 | L12500 X W3400 X H1600 |

| Detailed Images |

Automatic gluing stitching machine is new designed multi-function machine. It can do folding,

gluing and stitching one time to make standard RSC corrugated cartons.

| Feeding section1. Vacuum suction feeding to feed warping paperboard easily.

|

Gluing and Folding sectionSolid Beam Structure , not square tube !! 2. Stainless steel glue wheel adopted, long life and saving glue cost. |  |

| Stitching unit1. Double imported servo drive high precision,reduce the mechanical transmission part, and reduce the mechanical failure rate.2. Stitching department adopt the touch screen operation. Parameter (stitching distance, number, species and back baffle) could change expediently.3. Control system adopts Delta PLC control system. |

Counter and stacker section:1. Stacking and counting are simple and reliable. |

◆ The machine full computer control automatic tuning single,easy to operate,simple;Can store 1000 nail single.

◆ Screw mixer bottomleess with cover box can also be(when ordering);

◆ 3-5 minuters to adjust size,simple and quick;

◆ Nail head power for the servo motor,mechanical speed:800 nail/minuties.

◆ Pieces paper department adopts the vacuum adsorption front belt paper make sure the carton is not skewed ;The machine front feeder belts,belt height can be adjusted separately,increase service life;

◆ Pieces into the paper with side lapping device can send paper neatly smooth.

◆ Mixer feeding machine adopt servo motor control,to ensure that the nail from the stable and accurate;

◆ This machine design have box plastic function,ensure no scissors in nailing,neatly not skew;Before and after the machine to ensure the scissors mouth can't more than plus or minus 2 mm.

◆ In pieces the machine can be double screw, single screw, strengthen nails, double and screw and single head screw onetime complition ;

◆ The machine adopts computer screen operation,and display the fault description;

◆ In pieces the machine can be nailed three layer, five layer carton(statement in advance with order)is required for a seven layer;

◆ An automatic counting stacking quantitative output in pieces the machine finally.

◆ Pieces of native baling part for matching.

◆ Mixer machine during normal operation appear skewed,will automatically stop.

| Packing and Shipping |

Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road

transportation and various types of weather conditions. A full set of maintenance and operation

manuals is included.

|

| Our Services |

| Factory |