Cangzhou Zhaoli Import & Export Trade CO.,LTD. |

|

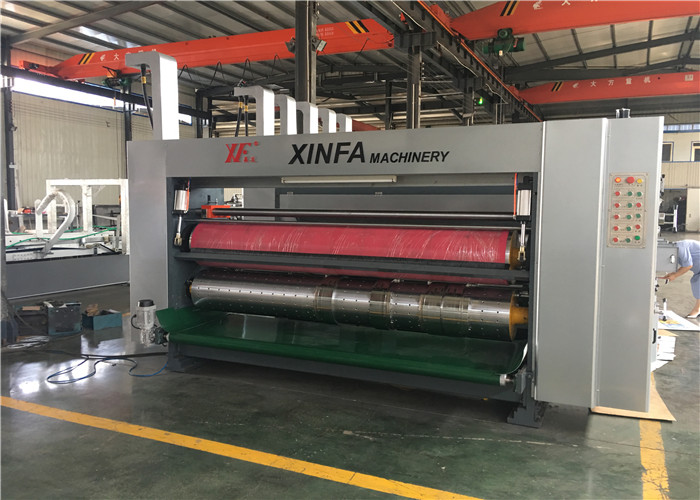

150 speed 3 or 5 layer corrugated carton flexo printer slotter die cutter machine

this machine is the carton forming machine from the corrugated cardboard sheet , through the printing , slotting / die cutting to make the cardboard which can fold to a carton .

Feeding unit :

Paper feeding roller

1) Seamless steel tube, coated with wear-resistant rubber, and balanced correction.

2) The diameter of the lower feeding embossing roller is 155mm , and chrome plating.

3) The clearance of the paper feed rollers is manually adjusted by double-pole self-locking worm gear body, and the clearance is adjusted by eccentric gear, marked with scale.

Auto back to zero device

1) The feed unit , printing unit are automatically reset to zero.

2) In general, the carton is equipped with automatic zeroing device, which can be adjusted to the correct position by two pieces of testing printing cardboard, to reduce the waste of cardboard.

Printing Unit

Steel anilox (made by Haili company from Jiangsu province)

1) The steel pipe surface adopts advanced chromium plating process, which is hard, smooth and wear-resistant.

2) The dot is consistent and the ink is even.

3) Extend the service life of printing plate and rubber roller.

4) Double-pole self-locking volute is adopted to manually adjust the anilox roller clearance, and eccentric steel sleeve is used to adjust the clearance, and the scale is marked.

Rubber roller

1) made by jizhou chunfeng .

2) The surface of steel tube is covered with wear-resistant rubber.

3) Special grinding in rubber roller, good ink transfer effect.

4) Double pole self-locking worm gear body is adopted to manually adjust the clearance between anilox and rubber roller, and eccentric gear is used to adjust the clearance, and the scale is marked.

Slotting Unit (Full Computer Adjustment)

1. Pre-creasing section

1) Pre-creasing shaft diameter 110mm, adopt high-quality seamless steel pipe. Surface grinding, dynamic balance correction, hard chrome plating, smooth rotation.

2) The pre-creasing wheel adopts advanced technology to improve the large pre-creasing wheel , so that the paperboard will not be broken when crease the line.

2. Creasing wheel section

1) The diameter of the creasing roller is 124mm, and high-quality seamless steel pipe is adopted. Surface grinding, dynamic balance correction, hard chrome plating, smooth rotation.

2) The creasing wheel adopts advanced technology. The upper wheel is made of high hardness resin glue and grooves in the middle. When passing the board synchronously with the lower wheel, the board line does not run away from the slant.

3) The axial position of the creasing wheel, the pre-creasing wheel and the slotting cutter disk is automatically adjusted synchronously through the precision ball screw.

4) The lower roller adjustment of the creasing wheel, pre-creasing roller, and slotting blade, adjustable eccentricity sleeve structure is adopted to make the structure compact, easy to adjust and accurate positioning;

5) The lower roller clearance adjustment of the creasing wheel, pre-creasing roller, and slotting blade are manually adjusted by the double-pole self-locking worm wheel body, and the clearance is adjusted by eccentric gear and marked with scale.

3. Pre-creasing, slitting and slotting blade seat

1) The upper roller diameter of slotting is 156mm, seamless steel tube, the two times of grinding, the surface hard chromium plating, moving smoothly.

2) The lower roller diameter of slotting is 156mm, seamless steel tube, the two times of grinding, the surface hard chromium plating, moving smoothly.

3) Precision machining of upper slotting blade disc.

4) Electric adjustment of synchronous axial position of the upper and lower slotting blade discs, the creasing wheel, the slitting knife disc and the pre-creasing wheel.

5) Single shaft-double blades slotting, the box height adjustment adopts the internal tooth electric control structure, so that the lubricating oil is not easy to contaminate the carton. And the box height adjustment has electronic collision protection device, will not damage the machine.

6) The guide plate traverse mechanism adopts the combination design of precision ball screw and linear optical axis, with flexible movement and accurate positioning.

Die Cutting Unit (can add slotting blade module)

1) The diameter of the lower die cutting roller is 360mm standard die cutting roller, which is made of alloy steel centrifugal casting with high precision grinding. It is equipped with grooved clamping fixture.

2) The rubber mat roller with high quality 45# steel finish machining, balance correction, hard chrome plating. The rubber mat adopts Depair brand from Germany - resistant polyurethane rubber sleeve with smooth incision, convenient installation and more than 8 million die-cutting times. Rubber mat roller adopt mechanical movement devices, every knife will cut in different positions, effectively prolong the service life of the rubber mat, movement distance is 30 mm, linear speed automatic compensation device, make the die cutting dis-infinite loop work in circumferential direction, to make the wear of rubber mat more uniform .

3) Automatic grinding mechanism of rubber roller, repair and polish the worn rubber mat multi times. The reuse rate of rubber mat has been greatly increased. The alarm lamp keeps flashing when the rubber roll is repaired.

4) Cleaning system: the front and back embossing shaft is pressed to the belt through the deceleration motor, and the waste of paper is removed completely, so that the machine will not be affected by the accumulation of the waste paper. The work efficiency is greatly improved.