CHINA YIKE GROUP CO.,LTD |

|

CHINA YIKE GROUP CO.,LTD

Web: www.yikegroup.net

Email: Anna@yikegroup.net

WhatsApp: +86 13363699514

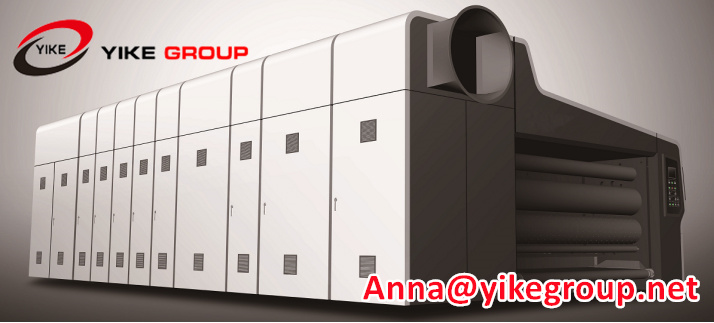

Low Noise Automatic Flexo Printer Slotter Machine For Carton Box Making

Detailed Product Description

| Type:: | Box Printing Machine | Color:: | Customer's Request |

| Max Machine Speed (pcs/min):: | 200 | Other Name: | Flexo Printer Slotter Machine |

| Driven Type:: | Electric | Keywords:: | Flexo Printing Machine |

| After-sales Service Provided:: | Engineers Available To Service Machinery Overseas | Partners: | Italy, UK, Poland, UAE, Africa, Mexico, Brazil And So On |

1. Feeder Unit

Lead-edge Feeding System

ü Lead-edge suction feeding system, easy operation, high accuracy,(adopts lead feeder system).

ü 7.5KW high pressure centrifugal fans, according to the cardboard

warping degree of frequency control pressure, to ensure warp

cardboard or thin cardboard high-speed accurate transmission.

ü Left and right side baffle position electrically adjustable,

screw-driven.and can remember by computer.

ü Front baffle adjust the position of the upper and lower intervals

synchronization by manual.

ü Skip-feeding devices, could select skip-feeding according to needs. To ensure that large-scale cardboard can also be processed.

ü Install 7” touch screen, could automatically display the

production quantity, production speed, and set the production quantity and every operating.

ü Slotting part is equipped with the interlock switch, to achieve the

emergency stop, stop feeding or feeding.

Machine Separation & Combination

ü Button switches electrically control the separation and combination

of machine, with automatic alarm device, continuously alarm while moving, to ensure safety of operators.

ü Air pressure interlocks, lock securely, conveniently and accurately.

ü Machine clutch drive shaft is equipped with overload protection device.

ü Active self-locking function: if unit is not completely locking state,

the host cannot start, to ensure the safety of machine and operator;

while host normal working conditions, the unit clutch function is automatically lock, to avoid machine misuse and personal injury.

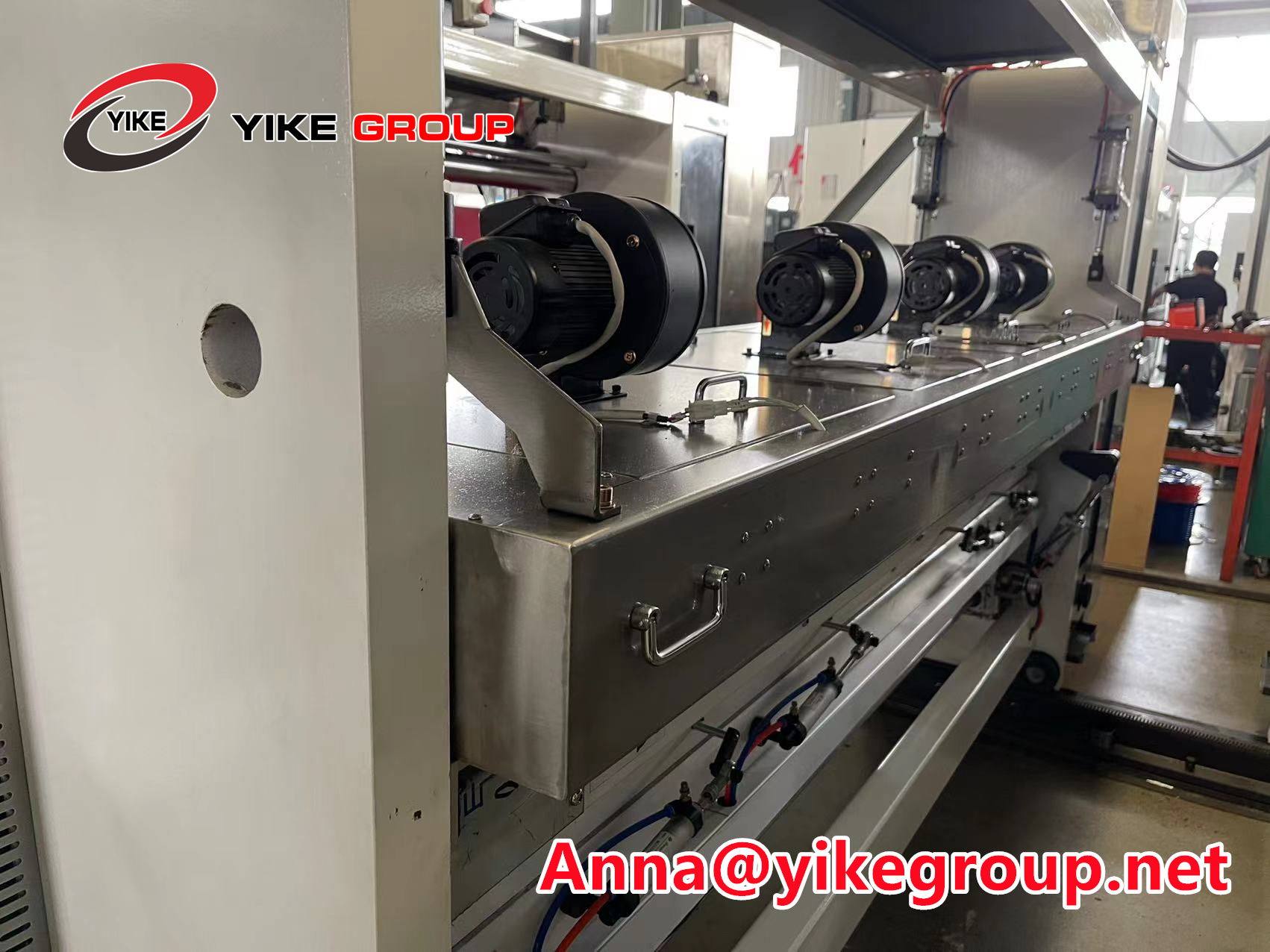

2. Printer Unit

Printing Roller

ü With printing plate, outer diameter φ450mm

ü High quality steel production, surface grinded, hard chromium-plated. Static balance adjustment, stable operation, suitable for high speed running

ü Roller horizontal direction and circumferential direction with datum line, convenient for align plate

ü Fixed coil axis, suitable for standard hanging slats, realize rapid change plate

ü Electric 360° adjust printing roller, automatic digital display adjustment,remember store digital.

ü Installed with foot switch to control plate roller reversing, convenient change plate

ü Auto-zero function,order memory.

ü Printing roller plate-change and fix-plate function.

ü Printing roll axial is adjusted left and right by manual,maximum movement left and right 10mm,auto-zero instruction.

3.Drying unit

►Vacuum adsorption ceramic wheels transfer, more rows ceramic wheels dislocation array to strengthen cardboard transmission stability.

►The bellows damper can adjust by automatic according to the cardboard size.

►Drying system with imported PLC program automatic controlling, man-machine dialog control and display.

►Automatic temperature control, fault alarm protection, automatic detection alarm, fault status display.

►Drying system with the host control starting and closing double protection, completely solve the cardboard directly irradiation time heat and burning this question when the machine stop.

Slotting Unit

►Single shaft five blades slotting ,an internal gear adjusts the height

of the carton box and prevents the lubricating oil from spilling or

leaking onto the cardboard

►The first pre-creasing,the cardboard not be damaged after prepressing.

►Upper creasing roll covered by anvil ring,so cardboard is not damaged

easily.

►Slotting bosses move along liner lead rails and are driven by lead

screws for flexible and precise movement.

►Upper boss and lower boss are coupled to keep the two knives aligned

while moving,which is helpful to prolong service life.

►Slotting register and height of carton box are digital controlled by

motor and PLC.

Die Cutting Unit

►Side to side oscillation of anvil drum(45mm)

►The die drum’s transverse movement can prolong the service life of

anvil cover.

►Die-cutting register is digitally controlled by motor and PLC

►The die-cut cylinder lateral register is digitally controlled by motor and

PLC,rang about±10mm

►Motorized caliper adjustment between anvil roll and die drum.

►Auto speed compensation system controlled by the independent motor

can achieve the superb die accuracy.

►Anvil rubber roller speed compensation adopted independent motor for

driving to control the rubber roller speed,the compensation scope is

±3mm.