Medium Voltage Power Cable single core

3.6/6 kV, 6/10 kV, 8.7/15 kV, 12/20 kV, 18/30 kV, 21/35KV, 26/35KV

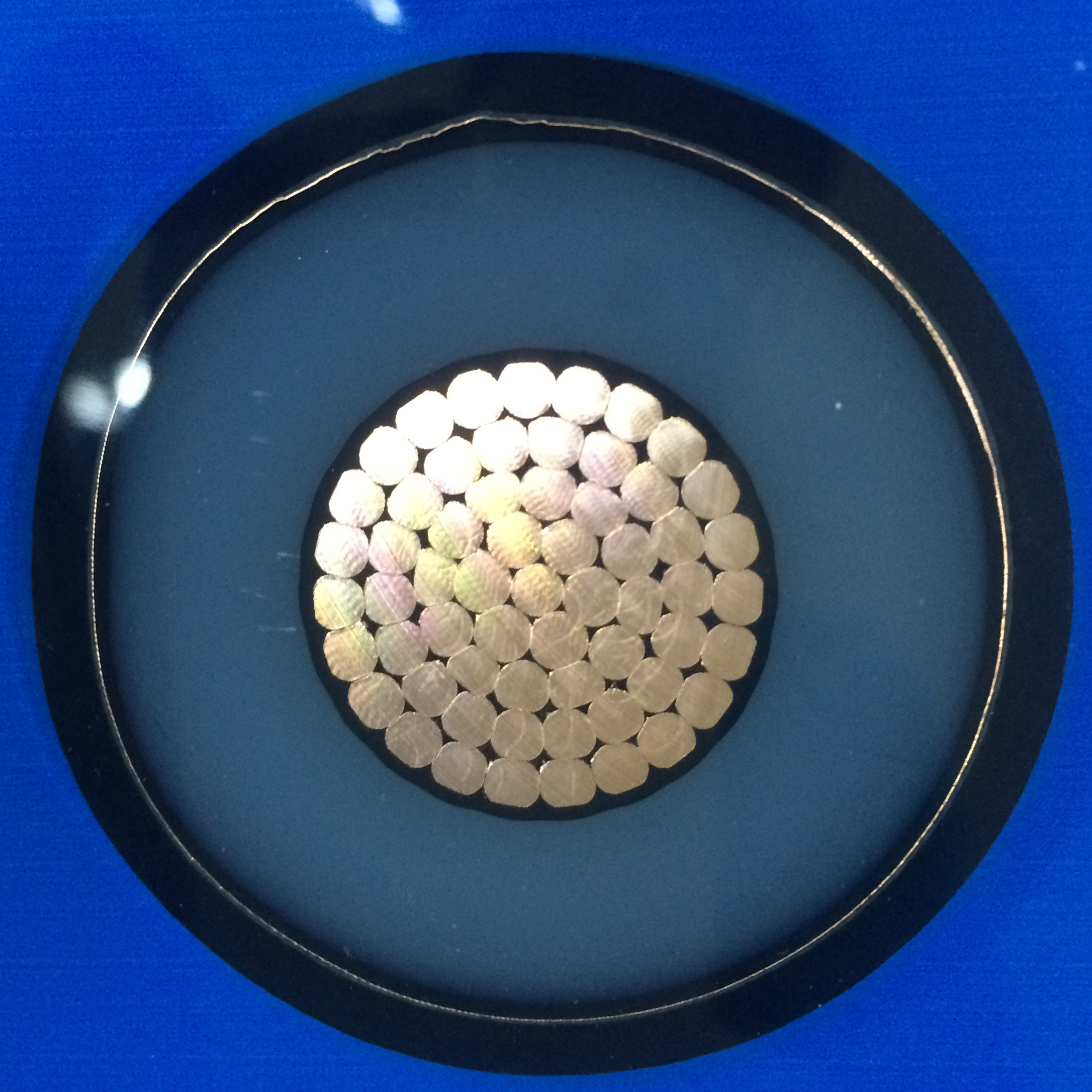

XLPE Insulated, Copper conductor, single core, screened, PVC sheathed

The single core cables are designed for distribution of electrical power with nominal voltage Uo/U ranging from 3.6/6KV to 26/35KV and frequency 50Hz.

They are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries, switchboards and power stations.

STANDER International:IEC60502-2 National:GB/T 12706.1-2008 CONSTRUCTION: 1. CONDUCTOR – Bare copper class 2 to IEC 60228, round, multiwire stranded and compact 2. CONDUCTOR SCREEN – Inner semi-conducting coating 3. INSULATION – Core insulation of cross-linked polyethylene (XLPE) 4. INSULATION SCREEN – Outer conductive layer extruded and per-manently welded with the core insulation Semi-conducting type 5. METAL SCREEN – copper tapes helically with a minimum thickness of 0,1 mm. Separator 6. SHEATH – Outer sheath of PVC compound PHYSICAL PROPERTIES: Temperature range Operating temperature Short circuit temperature Minimum bending radius |

|

Nominal /Operating /Testing Voltages

| Nominal voltage( U0/U) | Operating voltage 50 Hz | Test voltage(kV/5 min) |

| 3.6/6 kV | 7.2 kV | 12.5 kV |

| 6/10 kV | 12 kV | 21 kV |

| 8.7/15 kV | 17.5 kV | 30.5KV |

| 12/20 kV | 24 kV | 42 kV |

| 18/30 kV | 36 kV | 63 kV |

| 21/35 kV | 40.5 kV | 73.5 kV |

| 26/35 kV | 40.5 kV | 91 kV |

3.6/6 kV XLPE Insulated, Copper conductor, single core, screened, PVC sheathed

| No. of cores and nominal cross section | Operation voltage max. | Nominal voltage U0/U | Insulation thickness | Sheath thickness Nominal value | Outer Ø approx. | weight approx. | Current ratings in air 30℃ | Current ratings buried 20℃ | maximum DC resistance at 20℃ |

|---|---|---|---|---|---|---|---|---|---|

| mm² | kV | kV | mm | mm | mm | kg / km | A | A | Ω/km |

| 1 x 35 | 7.2 | 3.6 / 6 | 2.5 | 1.6 | 18.4 | 616 | 205 | 190 | 0.52 |

| 1 x 50 | 7.2 | 3.6 / 6 | 2.5 | 1.7 | 19.9 | 788 | 245 | 225 | 0.39 |

| 1 x 70 | 7.2 | 3.6 / 6 | 2.5 | 1.7 | 21 | 999 | 305 | 275 | 0.27 |

| 1 x 95 | 7.2 | 3.6 / 6 | 2.5 | 1.8 | 23.5 | 1276 | 370 | 330 | 0.19 |

| 1 x 120 | 7.2 | 3.6 / 6 | 2.5 | 1.8 | 24.9 | 1532 | 430 | 375 | 0.15 |

| 1 x 150 | 7.2 | 3.6 / 6 | 2.5 | 1.9 | 26.7 | 1849 | 490 | 425 | 0.12 |

| 1 x 185 | 7.2 | 3.6 / 6 | 2.5 | 1.9 | 28.3 | 2197 | 560 | 480 | 0.1 |

| 1 x 240 | 7.2 | 3.6 / 6 | 2.6 | 2.0 | 30.7 | 2763 | 665 | 555 | 0.08 |

| 1 x 300 | 7.2 | 3.6 / 6 | 2.8 | 2.1 | 33.7 | 3391 | 765 | 630 | 0.06 |

| 1 x 400 | 7.2 | 3.6 / 6 | 3.0 | 2.2 | 38.9 | 4433 | 890 | 725 | 0.05 |

| 1 x 500 | 7.2 | 3.6 / 6 | 3.2 | 2.3 | 42.2 | 5474 | 1030 | 825 | 0.04 |

| 1 x 630 | 7.2 | 3.6 / 6 | 3.2 | 2.4 | 45.6 | 6751 | 1190 | 940 | 0.03 |

6/10 kV XLPE Insulated, Copper conductor, single core, screened, PVC sheathed

| No. of cores and nominal cross section | Operation voltage max. | Nominal voltage U0/U | Insulation thickness | Sheath thickness Nominal value | Outer Ø approx. | weight approx. | Current ratings in air 30℃ | Current ratings buried 20℃ | maximum DC resistance at 20℃ |

|---|---|---|---|---|---|---|---|---|---|

| mm² | kV | kV | mm | mm | mm | kg / km | A | A | Ω/km |

| 1 x 35 | 12 | 6/ 10 | 3.4 | 1.6 | 20.6 | 687 | 205 | 190 | 0.52 |

| 1 x 50 | 12 | 6/ 10 | 3.4 | 1.7 | 22 | 855 | 245 | 225 | 0.39 |

| 1 x 70 | 12 | 6/ 10 | 3.4 | 1.7 | 23.6 | 1086 | 305 | 275 | 0.27 |

| 1 x 95 | 12 | 6/ 10 | 3.4 | 1.8 | 25.5 | 1351 | 370 | 330 | 0.19 |

| 1 x 120 | 12 | 6/ 10 | 3.4 | 1.8 | 26.9 | 1622 | 430 | 375 | 0.15 |

| 1 x 150 | 12 | 6/ 10 | 3.4 | 1.9 | 28.6 | 1932 | 490 | 425 | 0.12 |

| 1 x 185 | 12 | 6/ 10 | 3.4 | 1.9 | 30.3 | 2299 | 560 | 480 | 0.1 |

| 1 x 240 | 12 | 6/ 10 | 3.4 | 2.0 | 32.7 | 2864 | 665 | 555 | 0.08 |

| 1 x 300 | 12 | 6/ 10 | 3.4 | 2.1 | 35.3 | 3459 | 765 | 630 | 0.06 |

| 1 x 400 | 12 | 6/ 10 | 3.4 | 2.2 | 38.6 | 4554 | 890 | 725 | 0.05 |

| 1 x 500 | 12 | 6/ 10 | 3.4 | 2.3 | 42.2 | 5574 | 1030 | 825 | 0.04 |

| 1 x 630 | 12 | 6/ 10 | 3.4 | 2.4 | 45.9 | 6867 | 1190 | 940 | 0.03 |

8.7/15 kV XLPE Insulated, Copper conductor, single core, screened, PVC sheathed

| No. of cores and nominal cross section | Operation voltage max. | Nominal voltage U0/U | Insulation thickness | Sheath thickness Nominal value | Outer Ø approx. | weight approx. | Current ratings in air 30℃ | Current ratings buried 20℃ | maximum DC resistance at 20℃ |

|---|---|---|---|---|---|---|---|---|---|

| mm² | kV | kV | mm | mm | mm | kg / km | A | A | Ω/km |

| 1 x 35 | 17.5 | 8.7 / 15 | 4.5 | 1.7 | 22.9 | 779 | 205 | 190 | 0.52 |

| 1 x 50 | 17.5 | 8.7 / 15 | 4.5 | 1.7 | 24.2 | 952 | 245 | 225 | 0.39 |

| 1 x 70 | 17.5 | 8.7 / 15 | 4.5 | 1.8 | 26.1 | 1190 | 305 | 275 | 0.27 |

| 1 x 95 | 17.5 | 8.7 / 15 | 4.5 | 1.9 | 27.7 | 1461 | 370 | 330 | 0.19 |

| 1 x 120 | 17.5 | 8.7 / 15 | 4.5 | 1.9 | 29.3 | 1738 | 430 | 375 | 0.15 |

| 1 x 150 | 17.5 | 8.7 / 15 | 4.5 | 2 | 30.9 | 2054 | 490 | 425 | 0.12 |

| 1 x 185 | 17.5 | 8.7 / 15 | 4.5 | 2 | 32.7 | 2427 | 560 | 480 | 0.1 |

| 1 x 240 | 17.5 | 8.7 / 15 | 4.5 | 2.1 | 35.1 | 3001 | 665 | 555 | 0.08 |

| 1 x 300 | 17.5 | 8.7 / 15 | 4.5 | 2.2 | 37.3 | 3604 | 765 | 630 | 0.06 |

| 1 x 400 | 17.5 | 8.7 / 15 | 4.5 | 2.3 | 41.9 | 4702 | 890 | 725 | 0.05 |

| 1 x 500 | 17.5 | 8.7 / 15 | 4.5 | 2.4 | 45.4 | 5753 | 1030 | 825 | 0.04 |

| 1 x 630 | 17.5 | 8.7 / 15 | 4.5 | 2.5 | 49.1 | 7035 | 1190 | 940 | 0.03 |

12/20 kV XLPE Insulated, Copper conductor, single core, screened, PVC sheathed

| No. of cores and nominal cross section | Operation voltage max. | Nominal voltage U0/U | Insulation thickness | Sheath thickness Nominal value | Outer Ø approx. | weight approx. | Current ratings in air 30℃ | Current ratings buried 20℃ | maximum DC resistance at 20℃ |

|---|---|---|---|---|---|---|---|---|---|

| mm² | kV | kV | mm | mm | mm | kg / km | A | A | Ω/km |

| 1 x 35 | 24 | 12/ 20 | 5.5 | 1.8 | 24.9 | 860 | 205 | 190 | 0.52 |

| 1 x 50 | 24 | 12/ 20 | 5.5 | 1.8 | 26.4 | 1138 | 245 | 225 | 0.39 |

| 1 x 70 | 24 | 12/ 20 | 5.5 | 1.9 | 28.1 | 1281 | 305 | 275 | 0.27 |

| 1 x 95 | 24 | 12/ 20 | 5.5 | 1.9 | 29.9 | 1570 | 370 | 330 | 0.19 |

| 1 x 120 | 24 | 12/ 20 | 5.5 | 2 | 31.3 | 1839 | 430 | 375 | 0.15 |

| 1 x 150 | 24 | 12/ 20 | 5.5 | 2 | 33.1 | 2174 | 490 | 425 | 0.12 |

| 1 x 185 | 24 | 12/ 20 | 5.5 | 2.1 | 34.7 | 2540 | 560 | 480 | 0.1 |

| 1 x 240 | 24 | 12/ 20 | 5.5 | 2.2 | 37.1 | 3120 | 665 | 555 | 0.08 |

| 1 x 300 | 24 | 12/ 20 | 5.5 | 2.2 | 39.5 | 3746 | 765 | 630 | 0.06 |

| 1 x 400 | 24 | 12/ 20 | 5.5 | 2.3 | 44.1 | 4863 | 890 | 725 | 0.05 |

| 1 x 500 | 24 | 12/ 20 | 5.5 | 2.4 | 47.6 | 5905 | 1030 | 825 | 0.04 |

| 1 x 630 | 24 | 12/ 20 | 5.5 | 2.5 | 51.3 | 7220 | 1190 | 940 | 0.03 |

18/30 kV XLPE Insulated, Copper conductor, single core, screened, PVC sheathed

| No. of cores and nominal crosssection | Operation voltage max. | Nominal voltage U0/U | Insulation thickness | Sheath thickness Nominal value | Outer Ø approx. | weight approx. | Current ratings in air 30℃ | Current ratings buried 20℃ | maximum DC resistance at 20℃ |

|---|---|---|---|---|---|---|---|---|---|

| mm² | kV | kV | mm | mm | mm | kg / km | A | A | Ω/km |

| 1 x 50 | 36 | 18/ 30 | 8 | 2 | 32.6 | 1363 | 245 | 225 | 0.39 |

| 1 x 70 | 36 | 18/ 30 | 8 | 2 | 34.3 | 1614 | 305 | 275 | 0.27 |

| 1 x 95 | 36 | 18/ 30 | 8 | 2.1 | 36.1 | 1919 | 370 | 330 | 0.19 |

| 1 x 120 | 36 | 18/ 30 | 8 | 2.1 | 37.5 | 2203 | 430 | 375 | 0.15 |

| 1 x 150 | 36 | 18/ 30 | 8 | 2.2 | 39.3 | 2556 | 490 | 425 | 0.12 |

| 1 x 185 | 36 | 18/ 30 | 8 | 2.2 | 40.9 | 2934 | 560 | 480 | 0.1 |

| 1 x 240 | 36 | 18/ 30 | 8 | 2.3 | 43.3 | 3540 | 665 | 555 | 0.08 |

| 1 x 300 | 36 | 18/ 30 | 8 | 2.4 | 45.7 | 4191 | 765 | 630 | 0.06 |

| 1 x 400 | 36 | 18/ 30 | 8 | 2.5 | 49.1 | 5246 | 890 | 725 | 0.05 |

| 1 x 500 | 36 | 18/ 30 | 8 | 2.6 | 54.6 | 6561 | 1030 | 825 | 0.04 |

| 1 x 630 | 36 | 18/ 30 | 8 | 2.7 | 58.4 | 7906 | 1190 | 940 | 0.03 |

21/35 kV XLPE Insulated, Copper conductor, single core, screened, PVC sheathed

| No. of cores and nominal crosssection | Operation voltage max. | Nominal voltage U0/U | Insulation thickness | Sheath thickness Nominal value | Outer Ø approx. | weight approx. | Current ratings in air 30℃ | Current ratings buried 20℃ | maximum DC resistance at 20℃ |

|---|---|---|---|---|---|---|---|---|---|

| mm² | kV | kV | mm | mm | mm | kg / km | A | A | Ω/km |

| 1 x 50 | 40.5 | 21/ 35 | 9.3 | 2.1 | 34.8 | 1533 | 245 | 225 | 0.39 |

| 1 x 70 | 40.5 | 21/ 35 | 9.3 | 2.1 | 36.4 | 1791 | 305 | 275 | 0.27 |

| 1 x 95 | 40.5 | 21/ 35 | 9.3 | 2.2 | 38.3 | 2115 | 370 | 330 | 0.19 |

| 1 x 120 | 40.5 | 21/ 35 | 9.3 | 2.2 | 39.7 | 2408 | 430 | 375 | 0.15 |

| 1 x 150 | 40.5 | 21/ 35 | 9.3 | 2.3 | 41.4 | 2769 | 490 | 425 | 0.12 |

| 1 x 185 | 40.5 | 21/ 35 | 9.3 | 2.3 | 43.1 | 3167 | 560 | 480 | 0.1 |

| 1 x 240 | 40.5 | 21/ 35 | 9.3 | 2.4 | 45.5 | 3790 | 665 | 555 | 0.08 |

| 1 x 300 | 40.5 | 21/ 35 | 9.3 | 2.5 | 48.1 | 4481 | 765 | 630 | 0.06 |

| 1 x 400 | 40.5 | 21/ 35 | 9.3 | 2.6 | 51.4 | 5561 | 890 | 725 | 0.05 |

| 1 x 500 | 40.5 | 21/ 35 | 9.3 | 2.7 | 57.1 | 6894 | 1000 | 825 | 0.04 |

| 1 x 630 | 40.5 | 21/ 35 | 9.3 | 2.8 | 60.8 | 8263 | 1160 | 940 | 0.03 |

26/35 kV XLPE Insulated, Copper conductor, single core, screened, PVC sheathed

| No. of cores and nominal crosssection | Operation voltage max. | Nominal voltage U0/U | Insulation thickness | Sheath thickness Nominal value | Outer Ø approx. | weight approx. | Current ratings in air 30℃ | Current ratings buried 20℃ | maximum DC resistance at 20℃ |

|---|---|---|---|---|---|---|---|---|---|

| mm² | kV | kV | mm | mm | mm | kg / km | A | A | Ω/km |

| 1 x 50 | 40.5 | 26/ 35 | 10.5 | 2.2 | 37.6 | 1715 | 245 | 225 | 0.39 |

| 1 x 70 | 40.5 | 26/ 35 | 10.5 | 2.2 | 39.2 | 1980 | 305 | 275 | 0.27 |

| 1 x 95 | 40.5 | 26/ 35 | 10.5 | 2.3 | 41.1 | 2313 | 370 | 330 | 0.19 |

| 1 x 120 | 40.5 | 26/ 35 | 10.5 | 2.3 | 42.5 | 2612 | 430 | 375 | 0.15 |

| 1 x 150 | 40.5 | 26/ 35 | 10.5 | 2.4 | 44.2 | 2981 | 490 | 425 | 0.12 |

| 1 x 185 | 40.5 | 26/ 35 | 10.5 | 2.4 | 45.9 | 3387 | 560 | 480 | 0.1 |

| 1 x 240 | 40.5 | 26/ 35 | 10.5 | 2.5 | 48.3 | 4021 | 665 | 555 | 0.08 |

| 1 x 300 | 40.5 | 26/ 35 | 10.5 | 2.6 | 50.9 | 4725 | 765 | 630 | 0.06 |

| 1 x 400 | 40.5 | 26/ 35 | 10.5 | 2.7 | 54.2 | 5820 | 890 | 725 | 0.05 |

| 1 x 500 | 40.5 | 26/ 35 | 10.5 | 2.8 | 59.7 | 7142 | 1000 | 825 | 0.04 |

| 1 x 630 | 40.5 | 26/ 35 | 10.5 | 2.9 | 63.4 | 8528 | 1160 | 940 | 0.03 |

MEDIUM VOLTAGE CABLE TESTING

Routine tests: | Sample tests: | Type tests: |

These non-destructive tests are normally carried out on all lengths

manufactured. | These potentially destructive tests are normally carried out on

every production run. - Examination of conductor and dimensions - Hot set test for XLPE insulation - Insulation and oversheath thickness - Four hour voltage test | These destructive tests are normally carried out in addition to the

above tests on commencement of a particular cable supply to

validate its design. - Electrical type tests including bending and heat cycle - Non-electrical type tests including mechanical properties after ageing and tests under fire conditions. |

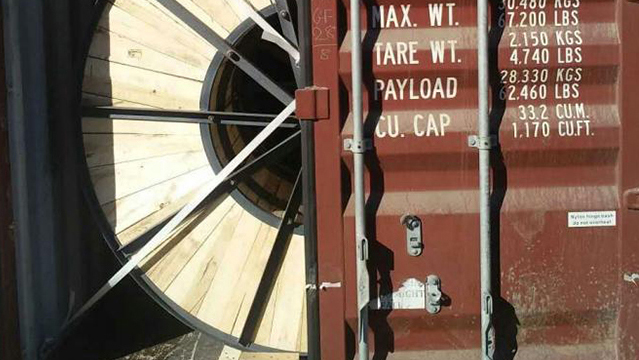

PACKING AND SHIPPING

Packing: steel wooden drum, other as required ; standard delivery length is 300 m

| Packaging details : | Delivery : | |

|  |

|

| Steel Wooden Drums | Cable Drum In container | shipped in 15 days after payment |

Cable Drum Data

| CABLE DRUMS | D1=Flange Diameter(mm) | W=Useful Width (mm) | D2=Barrel Diameter(mm) |

| 1000 | 700 | 500 |

| 1100 | 700 | 550 | |

| 1200 | 700 | 600 | |

| 1400 | 750 | 710 | |

| 1600 | 900 | 900 | |

| 1800 | 1120 | 1000 | |

| 2400 | 1150 | 1300 |

Delivery Port:

|  |  |

| Port of Shenzhen | Port of Hongkong | Port of Guangzhou |

Our production in numbers

| |

● Cable production started 1983 ● Sales in 2016 about 500 million USD ● 100,000 m2 Production area | ● 200 Sets Of Testing Equipment ● 100 Testing Items |

Shenzhen chengtiantai cable operates certified management systems compliant with:

| Certificat | Information | |

| ISO 9001:2008 Quality management systems | Certificat ISO 9001:2008 |

| ISO 14001:2004 Environmental management systems | Certificat ISO 14001:2004 - Shenzhen chengtiantai cable industry development Co.Ltd. ; Certified through Guangdong quality Testing CTC Certification Co.Ltd.; Valid until 13 January 2019 |

| OHSAS 18001:2007 Assessment specification for occupational health & safety

management systemsenvironmental management systems | Certificat OHSAS 18001:2007 - Shenzhen chengtiantai cable industry development Co.Ltd. ; Certified through Guangdong quality Testing CTC Certification Co.Ltd.; Valid until 13 January 2019 |

Manufacturing Process Of Medium Voltage Power Cable

Some great shots of our manufactering plant