FORPRO FORMWORK TECHNOLOGY (SHANGHAI) CO., LTD. |

|

Aluminum Formwork System Panel Concrete Construction For Wall and

Slab

Outline

Aluminium Formwork has been in operation across the globe in

countries such in Japan, Singapore to name a few for the

construction of both commercial and high rises. It comparatively

new in India. The Aluminium Formwork panels can be designed for any

condition/component of buildings and special architectural

features. This system is unique as all the components in a

building, starting from slabs to floors. The periphery of resulting

structure is concrete therefore we can control the concrete

quality, the durability of the structure increases. The formwork

system gives form to finish, eliminates the need for external and

internal plaster and through the system, the walls can be directly

painted with a minimal skim coat. Aluminium Formwork System is the

aptest to load bearing wall construction.

| Aluminium Formwork VS Wooded Formwork | |||

| Material cost (Included Support) | $183-216/m2 | $13--16/m2 | |

| cycles time | 200 times at least | 3-5 times | |

| Assembling and dismantling labor cost | $3.6-4.2/m2 | $4.2-4.7/m2 | |

| Recovery value | $67/m2 | $0.8/m2 | |

| Work effeciency | 20m2/day | 15m2/day | |

| Final economic index | $5.9-6.4/m2 | $12-13/m2 | |

Main components

1. Aluminiu panel system

Wall panel, Beam panel, Deck panel, KC, Stair, etc;

Width:100mm/200mm/300mm/400mm/600mm

2. Reinforcement system

Flat Tie, Steel waler, Vertical waler, Tie rod, etc;

3. Shoring prop system

Balancing, Raking shore, MB, EB, Horizontal rod, Adjustable prop,

Props; etc.;

4. Auxiliary system

KB, K screw, L screw, The drip line, Round Pin & Wedge pin,

Box, Working Stool, etc

Aluminum Formwork Feature

1. Short construction period---quickly removed system, about 3-4

days each floor

2. High reuse rate,low cost---one set aluminum shutters or formwork

can be reused up to more than 300 times.

3. Good stability, high bearing capacity--up to 60kN/m2, safe and reliabe

4. Extensive application---applied to all construction structure,

such as load bearing wall, column, beam, floor, stairs, balcony etc

5. Convenient assembly and disassembly, high efficiency--ligh

weight, easy for workers to install and move, no need technicians

6. Perfect concrete surface after taking down aluminum shutters or

formwork--- flat and smooth, without need to second plaster

7. Clean installation site, more safety--- all accessories are

re-used, no construction waste or nails left, neat and safe site

for workers.

8. No need to use plywood

Factory overview

Applications

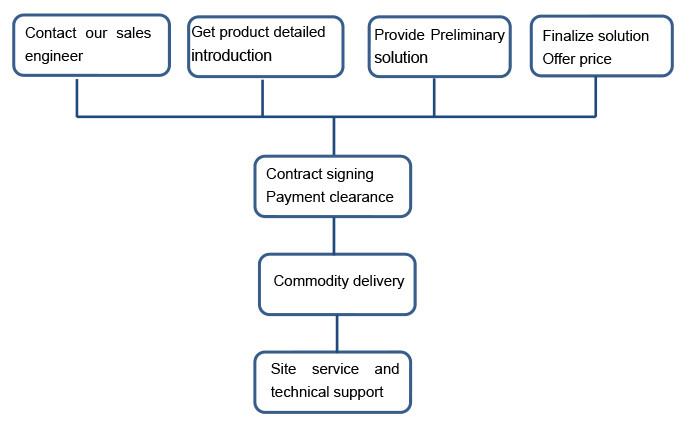

Delivery process