Zhengzhou Zhenheng Construction Equipment Co., Ltd. |

|

High Quality QTJ4-25 Concrete Brick Making Machinery Cement Block Making Machine

Description of QTJ4-25 Concrete Block Making Machinery

QTJ4-25 block making machine is simple and practical, novel and beautiful in appearance, and multi-purpose. It is not only suitable for the production of concrete blocks, but also for the production of fly ash, slag, slag and other material blocks. It can be installed with different molds to produce a variety of Specifications wall blocks, standard bricks, hollow bricks, porous bricks, etc.

QTJ4-25 brick making machine adopts special double-end composite output vibration technology to optimize the arrangement of vibrators, so that the exciting force is evenly distributed in the shaker. Realize the separate control of cloth and forming vibration, so that the cloth is homogenized and the forming is optimized.

The QTJ4-25 cement concrete block making machine adopts a unique platform mold compression vibration form, stable and reliable operation, hydraulic pressure combined with high-efficiency vibration molding, can fully liquefy the concrete in two to three seconds, and ensure the high density of the cut blocks and large block thickness ,Good quality. Reasonable raw material ratio can produce high-strength standard bricks, which can be stacked after forming, saving a lot of pallet investment.

Concrete Block Making Machinery Parameters of Model QTJ4-25

| Overall dimension | 5600*2240*2400mm |

| Main vibration form | platform vibration |

| Vibration frequency | 3500(r/min) |

| Pallet size | 850*550mm |

| Molding cycle | 25(s) |

| Exciting force | 50kn |

| Overall power | 20.6kw |

Productivity of QTJ4-25 block making machine

| Item | Size | Quantity per mold | Cycle molding | Per hour | Per day | Per year |

| Hollow brick | 390*190*190 | 4/pcs | 24-26(s) | 580pcs | 5800pcs | 1740000pcs |

| Porous block | 240*115*90 | 9/pcs | 22-25(s) | 1400pcs | 14000pcs | 4200000pcs |

| Standard brick | 240*115*53 | 21/pcs | 22-25(s) | 3300pcs | 33000pcs | 9900000pcs |

Performance of QTJ4-25 Block Making Machine:

1. This QTJ4-25 concrete brick making machine is with improved electronic control technology, reliable hydraulic system, integrated automatic control of machine, electricity, hydraulic pressure, simple operation and reliable operation.

2. The machine qtj4-25 cement block maker adopts table vibration, mold vibration and pressure head pressure vibration to produce blocks with uniform density and high strength.

3. The unique power feeding device and powerful material distribution mechanism ensure the excellent quality and high productivity of various blocks, which can reduce labor intensity.

4. Compared with traditional products, QTJ4-25 cement block making machine can save more than 20% of electricity.

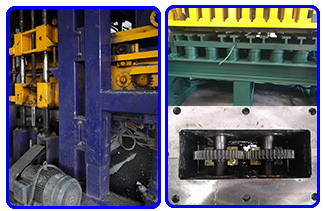

| High quality machine structure: |

| Production scope: Pavement block, riverside block, revetment block, square block, grassed block and color-face block (layered material feeding) etc. |

|

| Electrical system: |

| Feeding system: 360° feeding teeth rotate mixing raw material evenly Feeding box adopt double pulleys and pressing spring to prevent from scattering materials. Synchronizing gear: Guarantee accurate movement of the mold ,make mould pressing effective. |

|

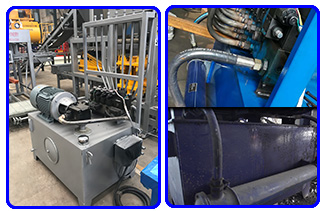

| Vibration system: |

| Hydraulic system: facilitated with imported hydraulic components and seal, high dynamic performance proportional valve, control oil quantity and pressure automatically. Water cooling system: ensure the oil temperature lower than 60°, extend the working time of hydraulic station with safety. |  |

| High quality Mould: |