Shenzhen ThreeNH Technology Co., Ltd. |

|

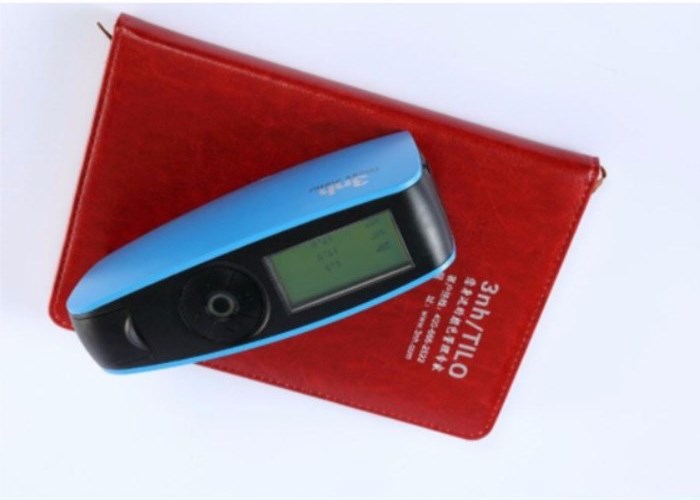

3nh GB/T 9754 Single Angle digital Gloss Level Meter NHG60 Stone Metal Film Aluminum Plate Analyzer

NHG60 Ink Paper digital Gloss Level Meter features with 60° angle, manufactured according to ISO2813 and GB/T 9754. It is also compatible with the standards of ASTM D523, ASTM D2457. NHG60 conforms to JJG696 first class gloss meter working requirement, corresponding with CIE 1931(2°) under CIE C light source.

NHG60 Ink Paper Gloss Meter can test material with gloss (0-1000Gu), and universally apply to paint, ink, stoving varnish, coating, wood products; marble, granite, vitrified polished tile, pottery brick and porcelain; plastic, paper; hardware industries, etc. for gloss measurement and gloss data transmission.

Features

1. 60° angle for semi gloss

2. Display 5 sets of measurement data, good for comparison

3. Measuring mode: basic measurement, statistical measurement, continuous measurement, QC measurement (only for GQC6 software).

4. Continuous mode to check uniformity over large areas

5. Connect to PC, more extend functions

6. Input gloss value manually

7. Large touch screen operation, easy to use

8. Beauty appearance, good man-machine communication interface

9. Powerful functions to meet many different requirements

10. Large storage to save over 5000 data

11. Built-in lithium ion rechargeable battery.

Product Details

Product Show

Specifications

| NHG60 60° Precise Ink Paper Gloss Meter | |

| Model | NHG60 |

| Measure Angle | 60° |

| Comply with standard ISO 2813,GB/T 9754,ASTM D 523,ASTM D 2457 | |

| Measuring Area (mm) | 9X15 |

| Measurement Range | 0~1000GU |

| Division Value | 0.1GU |

| Measurement Range Repeatability Reproducibility | 0-10GU 10-100GU 100-1000GU |

| ± 0.1GU ± 0.2GU ± 0.2%GU | |

| ± 0.2GU ± 0.5GU ± 0.5%GU | |

| Measurement Standard | Conform with JJG696 first class gloss meter working requirement |

| Chromaticity Corresponding | Corresponding with CIE 1931(2°) under CIE C light source |

| Errors | ±1.2 , ± 1.2% |

| Measuring Time | 0.5s |

| Dimension | L*W*H : 160mm*75mm*90mm |

| Weight | 350g |

| Language | Chinese/English |

| Battery | 3200mAh Li-ion Battery, >10000 times(within 8 hours) |

| Viewing Screen | TFT 3.5 inch, capacitive touch screen |

| Interface | USB/RS-232 |

| Data Save | Basic mode: 1000, Statistical Mode: 5000, Continuous mode : 5000 |

| Software | GQC6 Quality Control Software with QC report printing functions and more extended functions. |

| Operation Temperature | 0~40℃(32~104°F) |

| Storage Temperature | -20~50℃(-4~122°F) |

| Humidity | <85% relative humidity, no condensation |

| Standard Accessories | Power Adapter, USB cable, User Manual, CD (Including QC software), Calibration Plate |

| Optional Accessories | Miniature Printer |

| Note | The specifications are subject to change without notice. |

Related Ink Paper Gloss Meter Knowledge

Automotive Industry Ink Paper Gloss Meter

The automotive industry invests in delivering quality products with gloss and color levels that have maximum appeal to end customers. Gloss levels vary from mirror finish chrome parts to very matte "soft touch" internal plastics. The automotive interior design is getting more and more important in the purchasing decision. A big challenge for every car manufacturer is to achieve a "feeling" of high value and at the same time minimize cost. A variety of materials from leather to plastics, are used in the automotive field and need to be harmonized for color and gloss. A design team specifies the color, gloss and grain. Once a new color or material or process are approved, a new "style" is born, ready for implementation. In order to guarantee a uniform look among the various gloss levels in automotive parts, very tight tolerances are specified. Typical automotive gloss tolerances using a standard 60 degree gloss meter with gloss levels under 5 GU can be 0.3 or 0.5 GU. Visual assessment is impossible with these tight color and gloss tolerances.

As a starting point, master standard plaques are manufactured by the automotive customer with usually a flat and several grained areas. These are sent to the automotive suppliers as their gloss target to achieve with actual production parts.

As the master plaques and final parts are often made of different materials, the suppliers work closely with the automotive maker. At the end, the final approval on color and gloss are given on the automotive production part. This automotive production part now becomes the color and gloss standard for the supplier. Instead of working with absolute gloss numbers from the supplier production standard, QC needs to be based on the signed-off part. This procedure eliminates the reproducibility error as gloss is measured relatively on the sample type of material and same surface.

Since visual assessment of gloss is impossible one must use a digital gloss meter. Special gloss meters from 3nh with excellent precision are able to objectively control the production parts.

Two new methods for improved performance using gloss meters are now available to improve the accuracy and repeatability when measuring in the critical 60 degree low gloss range of 0 to 10 GU levels.

High gloss finish paints for bodywork are controlled for gloss using the 20° angle. Mid-gloss plastic and wood finishes are controlled using the 60° geometry and matte interior plastics can also be measured using the 85°. For automotive suppliers measuring automotive parts from glossy to matte, we have the

TRI gloss meter 268 series

Paints and Coatings Gloss Meter

Most paints and coatings are gloss controlled from formulation, checked regularly during manufacture and finally during application. Changes in gloss levels anywhere in this process can lead to substantial visual differences in batches offered to the end user. Closely controlling gloss means products are produced with maximum visual impact and rejections are avoided. The protective coatings industry monitors gloss during the lifetime of a coating because as the paint ages its gloss level drops. When it reaches a preset level the structure is re-painted ensuring that a maximum lifespan is achieved from the coating without the risk of corroding the structure it protects. Paints and coatings are primarily controlled using the 60° degree angle geometry, with the additional 20° and 85° geometries for high gloss and matte coatings.

Furniture Industry Gloss Meter

Furniture can be painted, coated, varnished or stained to any gloss level from very matte to the highest gloss. Throughout this process it is necessary to control the gloss of the products for batch consistency and to check that the coating has been applied and is drying correctly.

Unexpected gloss levels are often an early warning of a problem with the formulation of a coating, the amount that has been applied or the way it has cured.

The 60° geometry is standard in the furniture industry with some customers also specifying the additional 20° and 85° angles. Large coated surfaces can be checked for gloss variations in seconds using the "Continuous Read" feature which is standard in every Rhopoint Gloss meter.

Plastic Industry Gloss Meter

The plastic industry manufactures products of all shapes and sizes needing gloss measurement. Many of these, including plastic products for the construction industry such as trim for double glazed windows, are measured using the 60 degree angle.

Small gloss differences in these products can lead to rejections by customers and can be an indication of problems in the manufacturing process or the quality of the raw plastic material.

Metal finishing Gloss Meter

Metallic parts and products are often plated, finished with a protective coating or polished to make them attractive to the end user or as a functional protection from corrosion or wear As part of these processes, gloss is often used as a quality control measure. In the rolled steel industry a 45° gloss meter is used to assess the quality of the rolled steel. 60° and 20° gloss meters are used to check the finish on flat plated and polished metals. An Imbotec Gloss Sensor can also be used within the process.

It’s also used to assess the polishing on stainless steel pipe or the visual quality of items with a small surface are such as gold plated pen nibs or metal watch bracelets.

Polished Stone Gloss Meter

Natural stone is processed to produce items with many different finishes dependent on their end use. Marble and similar materials are polished to produce high gloss surfaces where other stone is left rough and matte in appearance.

The 3nh-Gloss meters are used to ensure batches of stone products match visually and to optimize the manufacturing process so that the correct amount of finishing is consistently applied to each surface. The three angles of our 20/60/85 degree Gloss meters give maximum flexibility with improved resolution on both matte and high gloss stone finishes.

Printing Industry Gloss Meter

Gloss is an indispensable measure in the printing industry. Packaging and magazine covers are regularly UV varnished for a quality glossy appeal to consumers and company brochures are given that professional edge with lamination and varnish to give contrasting matte and gloss effects.

Gloss reduction in a coating can also be an indication of a curing or drying problem. For example, a drop in the output of UV curing lamps can have disastrous effects on the quality of printed food cartons; uncured inks and coatings may rub off the paper or even contaminate the food the carton is meant to be protecting.

By monitoring the gloss of the UV varnish these problems can be avoided. The gloss variation across a large printed sheet can be assessed in seconds using the continuous read feature on our gloss meters. The gloss of paper is often quantified using a 75° TAPPI gloss meter.

Most gloss levels in this industry are often quantified using the 60° geometry guaranteeing consistency in the visual appearance of printed and finished products.

Shenzhen ThreeNH Technology Co., Ltd

Add: 4/F, Building 8, Nangang Second Industry Zone, Xili, Nanshan

District, Shenzhen, 518055 China.

Tel: 0086-755-27198826 Ext: 601

Fax: 0086-755-27190609

Mobile: 0086-13510878132

Email: y@3nh.com

Skype: y@3nh.com

WhatsApp/Wechat: 86-15019429968

Website: www.3nh.com/en

http://www.3nhq.com/