Wuxi Techwell Machinery Co., Ltd |

|

Verified Suppliers

|

|

Customized Cold Roll Forming Machine With Manual Decoiler For Making Roof Ridge Cap, Ridge Flashing

Description of Roof Ridge Cap, Ridge Flashing

Steeline Roll Top Ridge is a traditional style of ridge cap. Ridge capping provides an aesthically appealing finish as well as acting a as a watertight barrier. Roll Top Ridge is the most common type of Ridge Capping used. Steeline Roll Top Ridge is a high quality, durable and cost effective way to give your roof an attractive finish.

Main Technical Specifications of Roof Ridge Roll Forming Machine

Flowing Chart of Roll Forming Machine

Decoiler --- Feeding Guide --- Roll Forming --- Cut-to-length --- Run out Table

Main Components

| Decoiler | 1 Unit |

| Feeding guide | 1 Unit |

| Main roll forming machine | 1 Unit |

| Hydraulic cutting | 1 Unit |

| Hydraulic station | 1 Unit |

| PLC computer control | 1 Unit |

| Output table | 1 Unit |

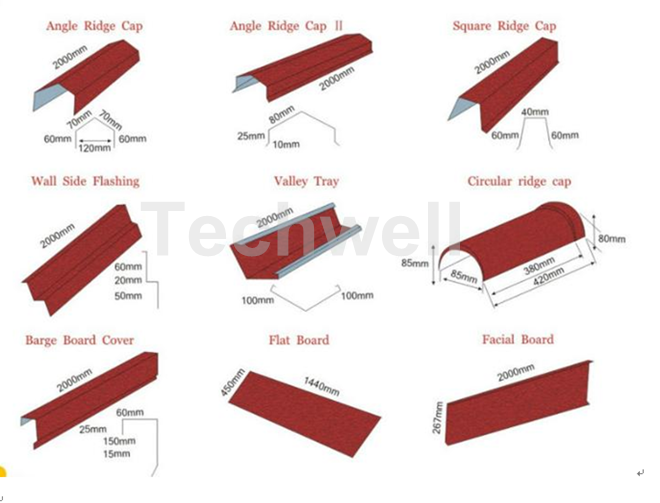

Reference Profile Drawing

|

|

More Machine Pictures

Contacts of WUXI TECHWELL

| Company | Wuxi Techwell Machinery Co.,Ltd |

| Website | www.wxtechwell.com www.cold-rollformingmachine.com |

| Email / Skype | sales@wxtechwell.com |

| Mob / Whatsapp | +86-15861597732 (Miss Lemon) |