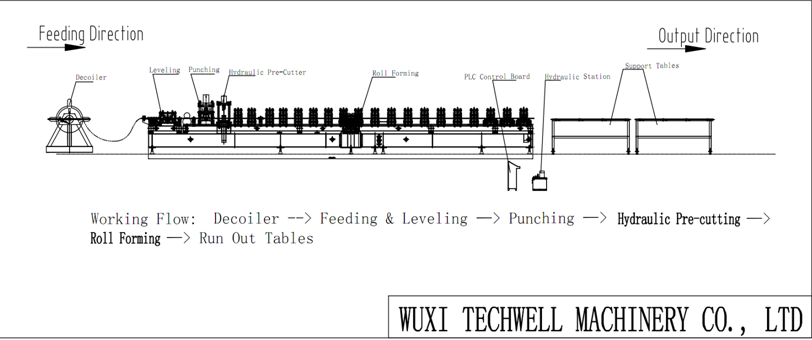

1). This C purlin roll forming machine adopts coil

production material to form C Profiles through 5 Ton manual

decoiler, pinch feeding, leveling rollers, Punching unit,

Pre-cutting, main roll forming part, hydraulic station, PLC control

system and Non-power type support table. |

2). The whole machine adopts PLC control, AC speed

control by frequency inverter technology, to realize continuous

auto production, which is the best desired machinery in steel

structure and metal cold roll forming machinery industry. |

3). Forming Speed: about 0-15m/min ( excluding punching & cutting time ) |

1). 5Ton Manual Decoiler

1. Machine frame: welding structure with shot lasting

treatment

2. Components: Base, brake device, inner hole support,

Expanding / tighten device

3. Weight capacity of decoiler: 5Ton Max.

4. Max. coil width: 500mm

5. Inner diameter of coil: 400-530mm

6. Outer diameter of coil: Max. 1500mm

|

2). Pinch Feeding & Leveling Device

1. 2 Rollers pinch feeding

2. 7 Rollers leveling ( Upper 3 rollers, lower 4 rollers)

3. Leveling roller diameter: about Φ 90mm

4. Leveling roller material: high grade 40Cr

5. Heat treatment of leveling roller: surface Hi-frequency

quench treatment

6. Motor power: about 4KW

7. The purpose of this unit is to guide the metal sheet into

the roll forming machine and make sure the metal sheet at the

correct position with the roll forming system.

8. It can be left and right adjusted the screw. Also the

left and right adjusting can be independent operating.

|

3). Hydraulic Punching Device

1. Punchign type: Hydraulic punching type

2. Punching Mould size: according to drawing

3. Hydraulic power: 5.5KW

|

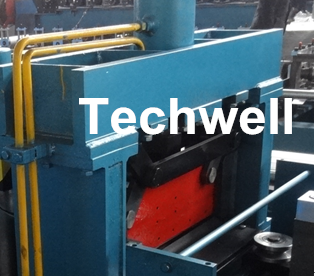

4). Hydraulic Pre-Cutting Device

1. Cutting type: Hydraulic flat cutting type, before roll

forming after punching

2. Material of blade: Cr12Mov with heat treatment ( HRC58-62 )

3. Length measuring: Automatic encoder length measuring,

brand: Omron

4. Tolerance of length:+/-1.5mm

5. No waste when cutting

6. And no need to change cutting die

|

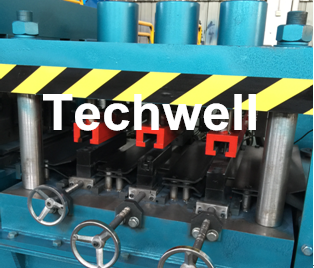

5). Main Roll Forming Part

1. Forming material thickness: 1.5-3.0mm

2. Forming material type: Mild steel. GI

3. Machine frame: high grade steel welded and tempering

treatment

4. Forming motor: about 15KW

5. Drive type: Chain drive

6. Shaft material: high grade 45# steel

7. Shaft diameter: Φ 80mm

8. Roller Material: GCr15 high grade steel ( HRC58-62 ), and roller surface with hard chrome ≥ 0.05mm

9. Forming speed: about 0-15m/min ( excluding cutting time )

10. Forming station: ≈ 16 stations

11. Calibration station: ≈ 2 stations

12. The gap between upper rollers and bottom rollers can be adjusted by screw

according to different thickness sheet

|

6). Electrical Control System

1. Adopts PLC control technology, frequency adjust speed technology,

realize the automatic production.

2. Provide good man and machine screen, which can

set the batches, plate length, and quantity.

3. Operation type: Touching screen + Button

4. Using encoder to calculate the number and

measuring the length

5. Electrical control: PLC frequency control

system with touch screen

6. PLC: PANASONIC Brand

7. Encoder: OMRON Brand

8. Size of PLC control board: 700mm (L) x 1000mm

(H) x 300mm (W)

|

7). Run-out Table

1. It is used to support the finished panels

2.Teh table we supply is 2 pieces with length of

2000mm, it can support panels with 10000mm at normal condition

3. The frame of supporter is welded by

square-steel

4. Simple non-power table type

|