Wuxi Techwell Machinery Co., Ltd |

|

Verified Suppliers

|

|

Bemo Panel Roof Roll Forming Machine for Making Roof Panel Sheet

A). Maintenance of Bemo Panel Roll Forming Machines

Daily maintenance plays an very importance role in extending the operation time and of Bemo panel roll forming machine and the good quality finished bemo roof. The following points should be part of the machine's daily production and usage routine.

B). Main Specifications of Bemo Panel Roll Forming Machines

| Item | Bemo Panel Roll Forming Machine | |

| Coil Material | Thickness | 0.3-0.8mm |

| Coil width | Custom-made | |

| Yield Strength | 250-350 Mpa | |

| Material | GI. Aluminium,PPGI, Color Steel, | |

| Decoiler / Uncoiler | Decoiler Type | Manual or Hydraulic or Auto Type |

| Coil Width | Max. 1250mm | |

| I.D | 508-610mm | |

| O.D | Max. 1500mm | |

| Bemo Panel Roll Forming Machine | Forming Stations | 13 Stations ( Depend on Profiles ) |

| Roller material | 45# steel, surface coated with 0.05mm hard chrome | |

| Diameter of shaft | 76mm | |

| Shaft material | High grade 45# steel | |

| Drive type | Chain transmission | |

| Forming speed | 0-15m/min | |

| Main power | 5.5KW | |

| Cutting System | Cutting type | Hydraulic cutting |

| Cutting Die Material | Cr12Mov steel, HRC58-62 | |

| Cutting power | 3KW | |

| CuttingTolerance | 10m+/-1.5mm | |

| Encoder | OMRON Brand | |

| Electrical Control Box | PLC | PANASONIC Brand |

| Inverter | YASKAWA Brand | |

| Touch screen | PANASONICE | |

| Operation type | Touch screen & Button | |

| Hydraulic Station | Hydraulic station | Famous Chinese brand |

| Support Tables | Table type | Simple nonpower type |

| Function | To support the finished panels | |

C). Main Components of Bemo Panel Roll Forming Machines

| Decoiler / Uncoiler | 1 Unit |

| Feeding Guide | 1 Unit |

| Main Bemo Panel Roll Forming Machine | 1 Unit |

| Hydraulic Cutting Device | 1 Unit |

| Hydraulic Station | 1 Unit |

| PLC Computer Control Board | 1 Unit |

| Runout Tables | 2 Units |

D). Working Flow of Bemo Panel Roll Forming Machines

Decoiler ---> Feeding Guide ---> Roll Forming --->

Cut-to-length ---> Run out table

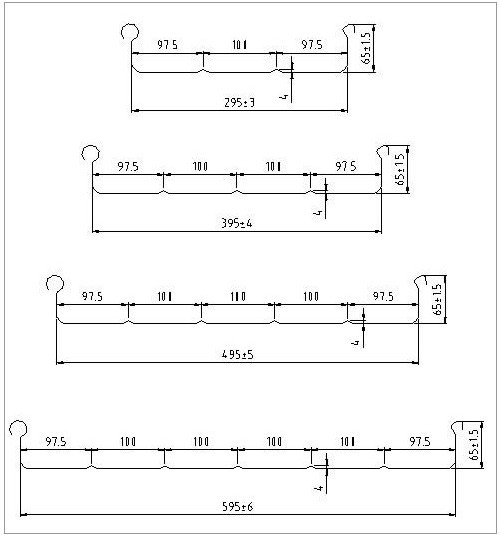

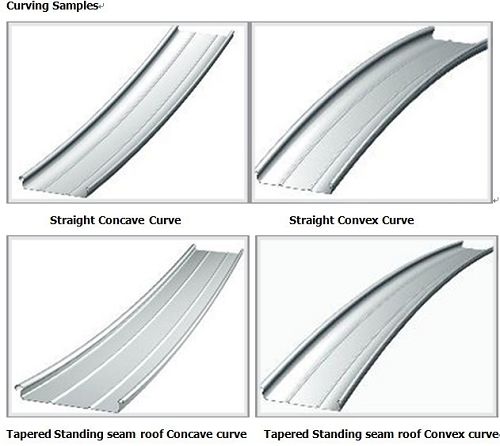

E). Reference Profile Drawings of Bemo Panel

F). More Pictures of Bemo Panel Roll Forming Machines

G). Contact Us Freely

| Company | Wuxi Techwell Machinery Co.,LTD |

| Website | www.cold-rollformingmachine.com |

| www.roofrollformingmachine.com | |

| www.wxtechwell.com | |

| Video | www.youtube.com/wxtechwell |

| Tel / Fax | 0086-510-83133431 |

| Mobile | 0086-18018304331 ( Miss Lee ) |

| monica@wxtechwell.com | |

| Skype | monica198614 |

| MSN | lixiaohua_monica@hotmail.com |

H). FAQ

Q: Do you have instruction manuals?

A: We provide you with instruction manuals, electricity layouts, civil requirements, and machine drawings.

Q: Once a machine arrives at our factory what happens then?

A: We will send you a technician or engineer that will commission and install your machine, with training for your staff if required at a separate fee.

Q: What do I need to offload my machine from the container?

A: You are not responsible for the offloading of your machinery, and it is recommended that you use a reputable rigging company.

Q: My current machine rollers need to be replaced. Would you be able to assist me?

A: Yes. Send us your profile and specifications then we will manufacture the rollers for you.