Wuxi Techwell Machinery Co., Ltd |

|

Verified Suppliers

|

G.i Coil / Carbon Steel Cold Roll Forming Machine for C Z Purlins

Of 1.5 - 3.0mm Thickness

Main Components

| Decoiler / Uncoiler | 1 Unit |

| Pinch Feeding & Leveling | 1 Unit |

| Punching | 1 Unit |

| Cutting | 1 Unit |

| Main Roll Forming Machine | 1 Unit |

| Hydraulic Station | 1 Unit |

| PLC Computer Control Board | 1 Unit |

| Runout Table | 2 Units |

Working Flow

Decoiler ---> Pinch Feeding & Leveling ---> Punching ---> Cutting ---> Main Roll Forming ---> Runout Table

Main Specifications

Coil Material | Thickness | 1.5-3.2mm |

| Coil width | Custom-made | |

| Yield Strength | 250-350Mpa | |

| Material | GI. Carbon Steel | |

| Purlin Sizes | Web width | 80-350mm |

| Height | 40-80mm | |

| Lip | 15-25mm | |

| C-C different sizes | Approx. 2-5 minutes | |

| Z-Z different sizes | Approx. 2-5 minutes | |

| C-Z or Z-C | Approx. 5-15 minutes | |

| Decoiler / Uncoiler | Coil Width | Max. 600mm |

| I.D | 508-610mm | |

| O.D | Max. 1500mm | |

| Coil weight | Max. 5 Ton | |

| Decoiler type | Manual type or Hydraulic or Automatic type | |

| Pinch Feeding & Leveling | Pinch feeding | 2 Units ( 4 Rollers ) |

| Leveling | 5 Rollers ( Upper 2 Rollers, Bottom 3 Rollers ) | |

| Punching | Punching type | Hydraulic Punching, Pre-punching |

| Punching die material | Cr12 Mov Steel, HRC58-62 | |

| Punching station | 1 or 3 or 3 Unites ( depend on hole patterns ) | |

| Punching in longitude controlled by PLC, punching at horizontal adjusted by manual hand wheel. | ||

| Cutting | Cutting type | Hydraulic Cutting, Pre-Cutting ( cutting sheet before forming ) |

| Cutting blades material | Cr12 Mov steel, with heat treatment HRC58-62 | |

| Length Measuring | Automatic length measuring by encoder & PLC. | |

| Cutting Tolerance | 10m +/-2mm | |

Roll Forming Machine | Forming Stations | 17 Stations |

| Rectifying | 1 Station | |

| Roller material | GCr15 steel, heat treatment | |

| Diameter of shaft | 80mm | |

| Shaft material | High grade 45# steel | |

| Drive type | Chain transmission, 1.2" Double chain | |

| Forming speed | 0-15m/min | |

| Main power | 15KW | |

| Servo motor | 2 Units | |

| Electrical control | PLC | PANASONIC Brand or Custom-made |

| Inverter | YASKAWA Brand or Custom-made | |

| Touch screen | MCGS Brand or Custom-made | |

| Operation type | Touch screen & Button | |

| Hydraulic Station | Hydraulic station | Famous Chinese brand |

| Hydraulic power | 7.5KW | |

| Runout Table | Table type | Simple nonpower type |

| Function | To support the finished panels | |

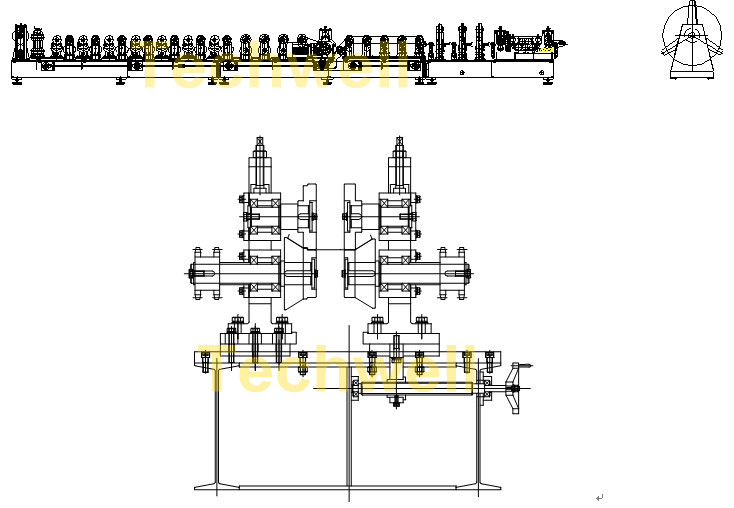

Reference Drawing

Our Advantage

Machine Pictures

Certificate