Jiangsu Co-effort Mechanical&Electrical Technology Co., Ltd |

|

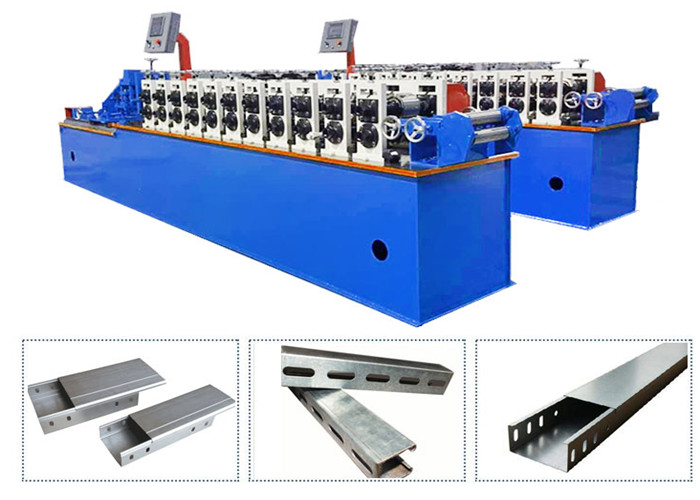

Automatic Steel Strut Channel Cable Tray Roll Forming Making with Punching Machine

Features and Applications of Cable Tray Roll Forming Machine

The cable tray is a special type of perforated cable tray electrical which provides good performance in commercial and light industrial electrical applications. Cable tray galvanized refers perforated cable tray whose surface is fabricated by using quality raw material Pre-galvanized.

The tray offers a 45 mm cable laying depth, with widths 150 mm, 300

mm, 450 mm, 600 mm and standard lengths of 3 m.

Flexible to install, its good performance combined with a visually

appealing profile in the electrical industry. For general use

indoor, with a clean looking finish, the tray is offered in

pre-galvanized steel, however,if use outdoor that need the extra

corrosion protection,hot dip galvanized after fabrication cable

trays are available.

Sizes of Struct Channel Cable Tray

| THICKNESS(Gage) | THICKNESS(mm) | SIZE(inch) | SIZE(mm) | SPAN OF HOLES | HOLE SIZE(mm) | TYPE | SURFACE FINISH |

| 19,16,14,12 | 1.0,1.5,1.6,2.0, 2.3,2.5,2.75 | 1-5/8" X1-5/8" | 41X41 | 50mm | 14X28 | SLOTTED,SOLID | H.D.G.,PG,SS,AI,PC |

| 19,16,14,12 | 1.0,1.5,1.6,2.0, 2.3,2.5,2.75 | 1-5/8" X13/16" | 41X21 | 50mm | 14X28 | SLOTTED,SOLID | H.D.G.,PG,SS,AI,PC |

| 19,16,14,12 | 1.0,1.5,1.6,2.0, 2.3,2.5,2.75 | 1-5/8" X1-5/8" | 41X41 | 50mm | 14X28 | SLOTTED,SOLID | H.D.G.,PG,SS,AI,PC |

| 19,16,14,12 | 1.0,1.5,1.6,2.0, 2.3,2.5,2.75 | 1-5/8" X13/16" | 41X21 | 50mm | 14X28 | SLOTTED,SOLID | H.D.G.,PG,SS,AI,PC |

| 19,16,14,12 | 1.0,1.5,1.6,2.0, 2.3,2.5,2.75 | 1-5/8" X1-5/8" | 41X41 | 50mm | 14X28 | SLOTTED,SOLID | H.D.G.,PG,SS,AI,PC |

| 19,16,14,12 | 1.0,1.5,1.6,2.0, 2.3,2.5,2.75 | 1-5/8" X13/16" | 41X21 | 50mm | 14X28 | SLOTTED,SOLID | H.D.G.,PG,SS,AI,PC |

Cable Tray Roll Forming Machine Main Components and Technical

Parameters

Automatic roll forming machine List

De-coiler------------------------------------------1set

Forming machine--------------------------------1set

Cutting device -----------------------------------1set

PLC control box ---------------------------------1set

Hydraulic pump station-------------------------1set

output table-----------------------1set

| 1 | Material thickness | 1mm-2mm |

| 2 | Feeding width | 300-700mm(acccodring profile drawing ) |

| 3 | Effective width | 100-600mm(acccodring profile drawing) |

| 4 | Forming Steps | 22steps |

| 5 | Line Speed | 8 to 12m/min(adjustable) |

| 6 | Stand | Independent stand structure (raft structure) |

| 7 | Drive | Independent motor and moved by chain |

| 8 | Material of Roller | 40Cr, HRC45-55 |

| 9 | Shaft Diameter | 80mm |

| 10 | Main Motor Power | About 30KW |

| 11 | Voltage | 380V/50HZ/Three Phase |

| Item | Parameters | Remark | |

| Suitable Material | Type | Hot rolled steel coil Galvanized steel coil | |

| Thickness | 1.8mm -2.0 mm | ||

| Yield Strength | 235-300MPa | ||

| Coil Width | 194mm-408mm | ||

| Producing Speed | About 6 m/min | Including punching time and cutting time | |

| Motor power of leveling device | 5.5 KW | ||

| Motor power of servo feeding device | 5.5 KW | ||

| Motor power of 110 tons punching device | 11 KW | ||

| Motor power of 250 tons punching device | 22 KW | ||

| Main motor power | 11KW | ||

| Roller change motor power | 1.5KW*2 | ||

| Hydraulic station power of Decoiler | 3KW | ||

| Hydraulic station power of Cutter | 5.5KW | ||

| Total power | 66.5KW | ||

| Power | AC380V,50Hz,3 Phase | ||

| Dimension (L×W×H, m) | About 30×4×4 | ||

Production Process and Struction of Cable Tray Roll Forming Machine

Decoiler → Leveling→ Feeding→ Punch Cutting → Forming → Collection

Table

Electric Elements Brand

| No | Items | Brand |

| 1 | PLC | Delta |

| 2 | HMI | WEINVIEW |

| 3 | Electric Elements | Schneider or Delixi |

| 4 | Bearing | HRB, WZS or LYC |

| 5 | Main Motor | Wannan motor |

| 6 | Servo Motor | Delta |

Cable Tray Roll Forming Machine Details