Jiangsu Co-effort Mechanical&Electrical Technology Co., Ltd |

|

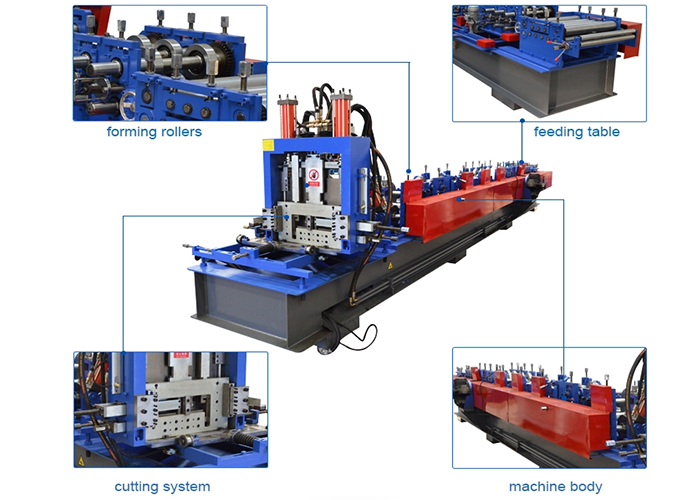

Fully Automatic C Z Metal Steel Section Channel Purlin Roll Forming Machine

Purlin Roll Forming Machine Description

C / Z purlin interchangeable roll forming machine is designed to

produce any size of C, Z steel purlins. The shape change, including

the cutting die from C to Z, can take up to 30 minutes (just take

out the clutch, open some hobs and insert the 180 ° rotation of the

clutch), and the size change can take up to 5 minutes (just input

the required distance through the touch screen on the PLC control

cabinet). This kind of quick change C / Z type steel purlin roll

bending forming machine improves the production efficiency.

Main Devices of Roll Forming Machine

| No | Items | Qty | Remark |

| 1 | De-coiler | 1 set | |

| 2 | Leveling | 1 set | |

| 3 | Roll Forming Device | 1 set | |

| 4 | Punching Device | 1 set | Optional |

| 5 | Cutting Device | 1 set | |

| 6 | Guarding Cover | 1 set | Optional |

| 7 | Control System | 1 set |

Technical Parameters of CZ Purlin Roll Forming Machine

| Item | Parameters |

| Coil Thickness | 1.5~3.2mm |

| Roll Forming Speed | 10~20m/min |

| Roll Forming Station | 18 Stations |

| Main Motor(KW) | 22kw (Hydraulic Motor ) |

| Main Shaft(mm) | 80mm |

| Shaft materials | 40Cr |

| Roller Materials | GCr15 |

| Cutting Method | Hydraulic Cutting (7.5KW) |

| Cutting Blade Materials | Cr12MoV |

| C Z Interchange | PLC control / Reverse roll |

| No | Items | Technical Parameters | |

| 1 | De-coiler | Width of Strip | ≤500mm; |

| Thickness of Strip | ≤3.2mm; | ||

| Inner Diameter of Coil | ф460-560 mm(according to customer’s requirements) | ||

| Outer Diameter of Coil | φ1500mm;Loading Weight:≤5T | ||

| Expand Way | Hydraulic,Manual | ||

| 2 | Roll Forming | Forming Station | 15 Stations |

| Driven | Gear boxes | ||

| Pitches of Passes | 600mm | ||

| Max. Width of Strip | 500mm | ||

| Max. Thickness of Strip | 3.2mm | ||

| Roller Shafts | Φ80mm ,40Cr (quenching and tempering) | ||

| Roller Material | Gr15,Hardness HRC58° | ||

| Main Motor Power | 45KW | ||

| Leveling Device | 7 rollers leveling, 1 set | ||

| Turk heads | 1 set | ||

| 3 | Cutting Device | Cutting Way | Hydraulic |

| Cutting Accuracy | Length Encoder Control Full Length (±2MM) | ||

| Material of Cutting Blade | Cr12MoV | ||

| 4 | Unloading | The blanking rack is welded with channel steel. The conveying drum is installed on the channel steel. The workpiece is pushed into the finished product collection frame by cylinder on the roller rack. | |

| Manual blanking structure | Rollers | ||

Electric Elements Brand

| No | Items | Brand | Remark |

| 1 | PLC | Mitsubishi | |

| 2 | HMI | WEINVIEW | |

| 3 | Electric Elements | Schneider | |

| 4 | Bearing | HRB/LYC/ZWZ | |

| 5 | Main Motor | China Brand- Xin Dali | As your requirements |