Jiangsu LCD Technology Co., Ltd |

|

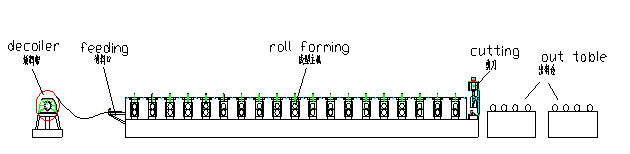

Working procedure

Uncoiler—Feeding—roll forming--- hydraulic cut to length—output table

Main technical parameters

The machine introduction

This machine is include a decoiler( can both be manual or hydraulic), feeding, leveling, roll former, hydraulic and an output table, it is automaticlly change the sizes by the PLC control system, you can confirm a drawing of the roof sheet and we will design the machine for you.

The usage of the machine

This machine is used for producing corrugated roof panel, normally is color steel roof panel, also can do alluminum material, there are many standrad drawings, like 1250mm, 1200mm, 1000mm, 914mm, etc.

We have professional technicain team to design the machine according to your requirements.

After sale Services

1). Engineer will give free training lessons to labors in buyer’s factory.

2). The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 for engineer.

3). During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, we will provide the buyer spare parts at cost price.

We will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

Machine pictures