Dongguan Hezhi Hardware Co., Ltd. |

|

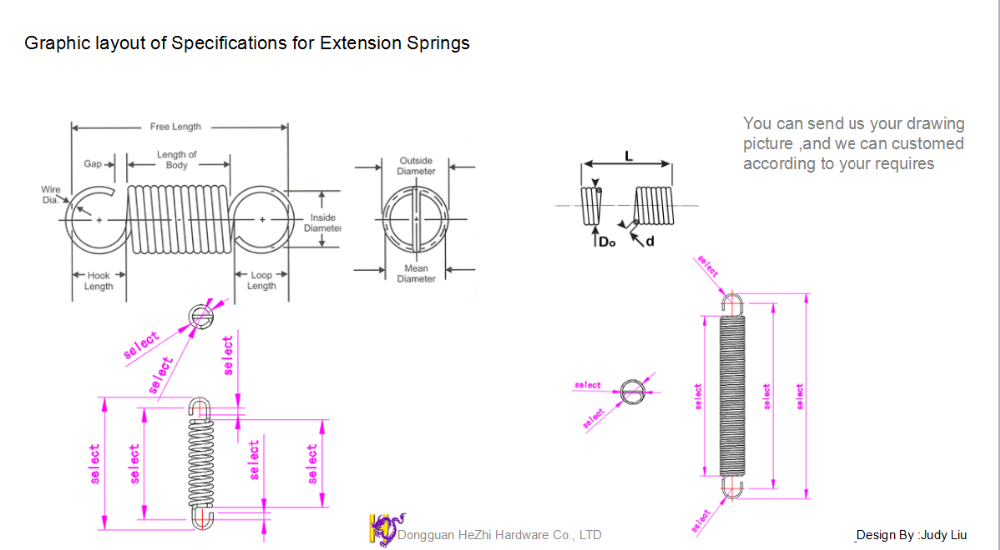

Music Wire With Nickel Plating Extended Coil Springs For Furniture

Extension Spring, also known as spiral stretching spring, is generally equal pitch, the cross-section is round, they can be used in many occasions, such as production and assembly, experiment, research and development, maintenance, etc.. Tension springs occupy an important position in the global market, widely used in national defense, Marine, computer, electronics, automobile, mold, medicine, biochemistry, aerospace, railway, nuclear power, wind power, thermal power, construction machinery, mining machinery, construction machinery, elevator and other fields.

| Material | Stainless Steel (SUS304,301.316,310,201,631, ect) | |

| Paino/Music Steel | ||

| Carbon Steel or as your requirments | ||

| Iron etc | ||

| Finished | Electroplating | Zinc ,Nickel ,copper ,black and so on |

| Heating | In different tempurture | |

| Cleanning | Passivation,Clean,Rust-Proof | |

| Process | CNC Machine | |

| Application | used in computer, electronics, home appliances, cameras, instruments, doors, motorcycles, harvesters, automobiles, and other industries to control the movement of machine parts, ease impact or vibration, storage energy, measure the size of force and so on! | |

| Wire diameter Range | 0.05mm-20mm | |

| Design | According to customer's drawing or sample | |

| Packaging | PE Bag+carton Box, inner plastic bags and outer carton | |

| Material | Type | Model number | Characteristic | Application |

| Stainless Steel (SUS) | With or without magnetism shine or nitrided surface, dark surface | 201, 202 etc. | Less nickel plated, could not proceed salt spray test | General using craft and toys |

| 301, 302, 303, 304, 305, 310, 316, 321 | High temperature resistance | Electronic part, home appliance, Locks, toys or can be used in all kinds of products. | ||

| 410, 420, 430 etc. | High strength | OEM aments and tableware products | ||

| 630, 631 etc. | High heat stability | Electrical application or product use under high temperature | ||

| Carbon Steel (SWC) | Low carbon steel, high carbon steel, nickel plated steel, Galvanized wire | 55CrSi, 60SizMNA, 60SizCRVA | Good elasticity high hardness | Electronic part, home appliance, Locks, toys or can be used in all kinds of products. |

| Piano Steel (SWP) | SWP-A, SWP-B | High tensile resistance, and long worklife | Application for all kinds of small products | |

| Copper Wire | Phosph or copper wire( C519R), Nickel plated copper, Bronze | Good conductivity of electrical | Electronics, electrical applicance, like antenna | |

| Iron | Galvanize iron wire | Customized or normal material | Soft material | Craft spring, decoration wire |

1. What is a extension spring?

Extension springs are designed to absorb and store energy as well

as create a resistance to a pulling force. The “initial tension” is

created during manufacturing when the wire is rotated backwards

during coiling. It is initial tension that determines how tightly

together an extension spring is coiled.

2. What is spring rate extension spring?

Extension Spring Rate:

The change in load per unit of deflection, generally expressed in pounds force per inch. Spring rate is determined by the amount of force, in pounds, required to extend a spring by one inch. Material size directly impacts spring rate.

3. What is the difference between compression and extension

springs?

One way to describe the primary difference between compression and

extension springs is their load at zero deflection. Compression

springs have zero load at zero deflection. Extension springs, on

the other hand, experience a load at zero deflection due to their

initial tension.

4. What is the difference between torsion and extension springs?

Extension springs fully expand and contract when operating an

overhead door. Torsion springs turn. Torsion springs are sturdier

and last longer. Torsion springs do cost more, but generally last

between 15,000 and 20,000 cycles, whereas extension springs last up

to 10,000 cycles.