Xi'an Yuechen Metal Products Co., Ltd. |

|

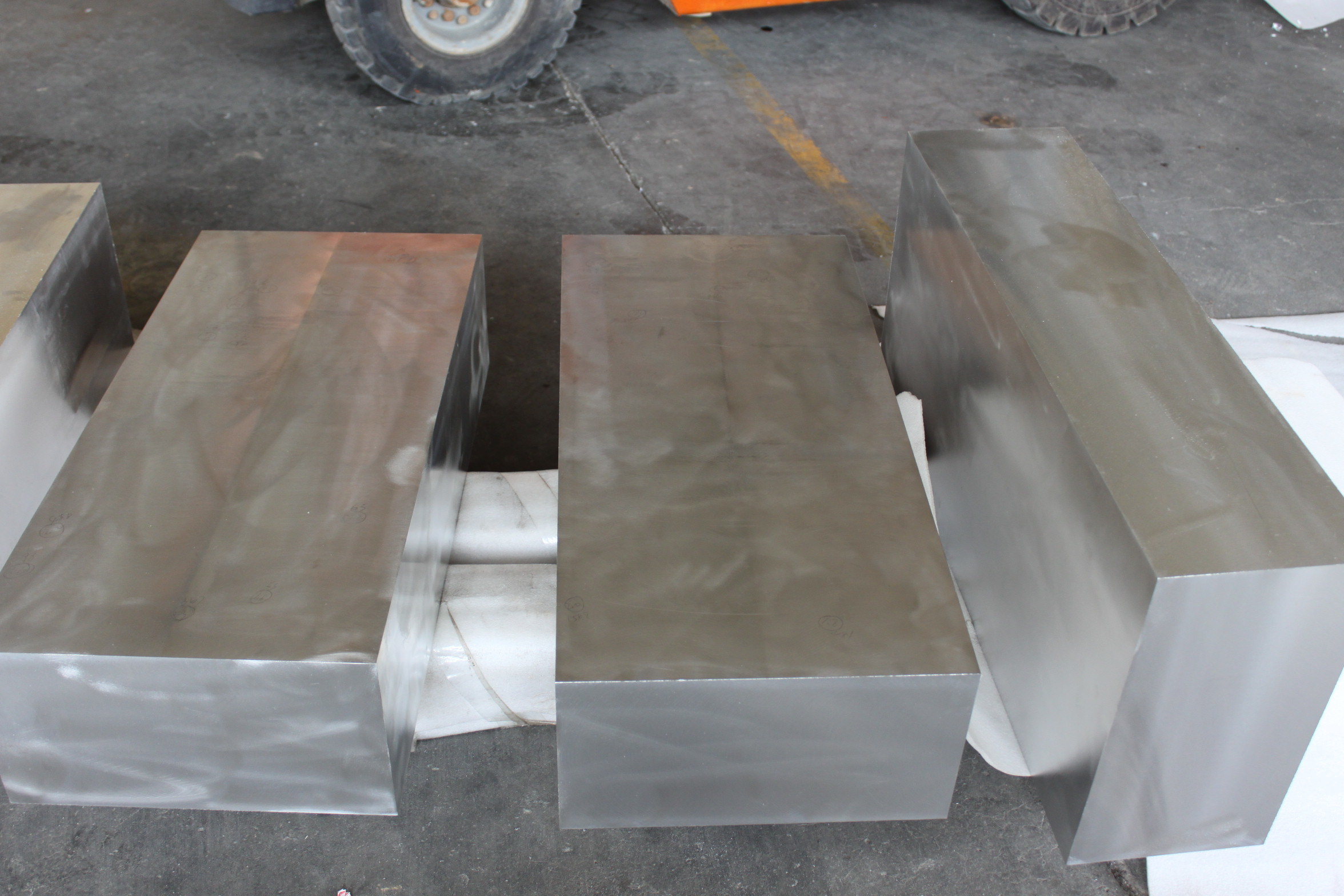

High strength forged AZ91D magnesium alloy plate slab block ZK60A disc cube fast machining saving costs

Xian Yuechen Metal Products. Co., Ltd. (XYMCO) has started to produce the forged magnesium alloy plate, forged magnesium alloy slab, forged magnesium alloy cube, forged magnesium alloy disc, forged magnesium alloy block and forged magnesium alloy billet from 2004.

AZ31B is a wrought magnesium base alloy with good room-temperature strength and ductility combined with corrosion resistance and weldability. Increased strength is obtained by strain hardening with a subsequent partial anneal (H24 and H26 tempers).

AZ80A is the strongest of the AZ alloy family, offering good strength at ambient or medium temperatures up to 120˚C (250˚f). It has good corrosion resistance and can be forged for good properties. Recent improvements on microstructure and cleanliness makes our AZ80 ideal for high-performance forging applications.

ZK60A is the typical legacy magnesium forging alloy. Current and historic uses are in military rotor and aircraft while the largest volume application is forged magnesium wheels for motorsport. This high strength alloy has good corrosion resistance but requires a coating for all applications.

Max. dimension:

For blocks: 350mm x 500mm x 500mm

For billet: Dia. 350 x 1000mm

SPECIFICATIONS

Available alloys: AZ31B, AZ61, AZ80 and ZK60A

Specification: ASTM B91-97 and GB standard

PHYSICAL PROPERTIES

Density: 1.78

Coefficient of thermal expansion: 26.8 x 10-6K-1

Specific heat: 1040 Jkg-1k-1

Thermal conductivity: 76.9Wm-1k-1

Electrical resistivity: 92nΩm

Modulus of elasticity: 45 x 109Pa

Poissons ratio: 0.35

Melting range: 566 - 632°C

HEAT TREATMENT

No thermal treatment is available for increasing the strength of this alloy after fabrication.

MECHANICAL PROPERTIES

| Alloy and Temper | Thickness (mm) | Yield Strength 0.2% offset (MPa) | Tensile strength (MPa) | Elongation In 5.65 √A (%) |

| AZ31B-O | 0.5 – 1.5 | 125 | 221 | 10 |

| 1.5 – 6.3 | 105 | 221 | 9 | |

| 6.3 - 75 | 105 | 221 | 8 | |

| AZ31B-H24 | 0.5 – 6.3 | 200 | 269 | 5 |

| 6.3 -9.5 | 179 | 262 | 7 | |

| 9.5 – 12.7 | 165 | 255 | 8 | |

| 12.7 - 25 | 152 | 248 | 8 | |

| 25- 50 | 138 | 234 | 6 | |

| 50 - 80 | 124 | 234 | 7 | |

| AZ31B-H26 | 6.3 - 10 | 186 | 269 | 6 |

| 10 – 12.5 | 179 | 262 | 6 | |

| 12.5 - 20 | 172 | 255 | 5 | |

| 20 – 25 | 159 | 255 | 5 | |

| 25 - 40 | 152 | 241 | 5 | |

| 40 - 50 | 148 | 241 | 5 |

The sheet and plate shall conform to the tensile requirements in above Table unless other agreement is made between seller and purchaser. Mechanical Properties for sizes and tempers not shown in above Table shall be as agreed upon by seller and purchaser.

OTHER PROPERTIES

Typical Hadness

O temper: 67 Rockwell E

H24 temper: 83 Rockwell E

WELDABILITY

Excellent weldability with gas shielded arc using AZ61A (preferred) or AZ92A filler rod; post weld stress relief is required to prevent stress corrosion cracking. Resistance welding is excellent.

MACHINING

AZ31B, like all magnesium alloy sheet and plate, machines faster than any other metal. Providing the geometry of the part allows, the limiting factor is the power and speed of the machine rather than the quality of the tool material. The power required per cubic centimeter of metal removed varies from 9 to 14 watts per minute depending on machining operation.

DENT RESISTANCE

Weight for weight, AZ31B-H24 has proven to be superior to competitive materials in its resistance to denting at moderate energy levels.

Dent Resistance of 1mm Gauge Sheet (Dent depth in mm from 25mm spherical redius indentor on 350mm span)

| Impact Energy 0.34 J | Impact Energy 0.62 J | Impact Energy 1.25 J | |

AZ21B-H24 6061 – T6 3003 – H14 5052 – H34 2024 – T6 SAE 1010 Mild Steel | 0.66 0.94 2.24 1.55 0.99 1.09 | 1.42 1.52 3.23 2.41 1.52 1.70 | 2.34 2.46 4.90 3.35 2.29 2.67 |

SURFACE TREATMENT

All the normal chromating, anodizing, plating, and finishing treatment are readily applicable. AZ31B also responds well to plasma electrolytic oxidation finishing.

CORROSION RESISTANCE

Continuous exposure for 2.5 years.

Marine Atmosphere

AZ31B-H24 0.008mg.cm-2d-1

Mild steel 0.323mg.cm-2d-1

Industrial Atmosphere

AZ31B-H24 0.013mg.cm-2d-1

Mild steel 0.055mg.cm-2d-1

Rural Atmosphere

AZ31B-H24 0.006mg.cm-2d-1

Mild steel 0.032mg.cm-2d-1

ZK60A

ZK60A is a wrought magnesium base alloy containing zinc and zirconium. Increased strength is obtained by artificial aging from the as-fabricated form. ZK60A-T5 has the best combination of strength and ductility at room-temperature of the wrought magnesium alloys.

APPLICATIONS

Forgings and extrusions in ZK60A find application in high strength parts for use primarily where the service temperature is below 150°C. ZK60A forgings can be used where pressure tightness or machinability are required. That parts are dimensionally stable during and after machining is also an important design consideration.

Forgings and extrusions in ZK60A find application in high strength parts for satellites, helicopter gearboxes and rotor hubs, bicycle frames, roadwheels, missle frames and interstage fairings, brake housings and landing gear struts.

SPECIFICATIONS

ASTM B91

ASTM B107/B107M-13

CHEMICAL COMPOSITION

Zinc 4.8-6.2%

Zirconium 0.45% min

Magnesium Balance

Dimension Scope

Forgings: Max. length 1000mm, max. width 500mm, max thickness 330mm.

Extrusions: Diameter 6mm - 180mm for round bar; thickness and width 10-220mm for square/rectangular section. Length: 100mm - 6000mm

Thickness and width are inter-dependant.

HEAT TREATMENT

As-fabricated (F) forgings can be converted to the precipitation treated temper (T5) by heating to 150°C for 24 hours, followed by air cooling.

PHYSICAL PROPERTIES

Specific Gravity 1.83

Coefficient of Thermal Expansion 27.1x10 -6 K -1

Thermal Conductivity 121 Wm -1 K -1

Specific Heat 1100 Jkg -1 K -1

Electrical Resistivity 57 nΩm

Modulus of Elasticity 45GPa

Poissons Ratio 0.35

Melting Range 520-635°C

TYPICAL HARDNESS

ZK60A-T6 85 Rockwell E

ZK60A-T5 77 Rockwell E

WELDABILITY

ZK60A is not considered to be weldable by conventional techniques due to hot-shortness cracking. However, resistance welding response is excellent. Friction stir welding can be used to join ZK60A to itself and other magnesium alloys.

MACHINING

ZK60A, like all magnesium alloy forgings, machines faster than any other metal. Providing the geometry of the part allows, the limiting factor is the power and speed of the machine rather than the quality of the tool material. The power required per cubic centimeter of metal removed varies from 9 to 14 watts per minute depending on the operation.

SURFACE TREATMENT

All the normal chromating, anodizing, plating, and finishing treatments are readily applicable.

Our Services:

1. Small order quantity available

2. Professional engineering team and sales team

3. Payment: T/T & Western Union

4. OEM/ODM Supporttable

5. Free samples provided

6. Competitive price and high quality

FAQ:

1. Q: Are you a factory or trading company?

A: We are direct manufacturer located in Xi'an, Shaanxi province,

and have our equipment!

2. Q: Are your products customized?

A: Yes,the products in the website are only the common type or the

previous types, we can supply the new products according to your

requirements or drawings.

3. I do not know how to use your product ?

Do not worry ! We can supply technical guidance together with

products.

4. Q: How can I get some samples?

A: Several samples are freely offered for buidling the business

long-term relationships and letting our customers believing the

quality of our products.