Xi'an Yuechen Metal Products Co., Ltd. |

|

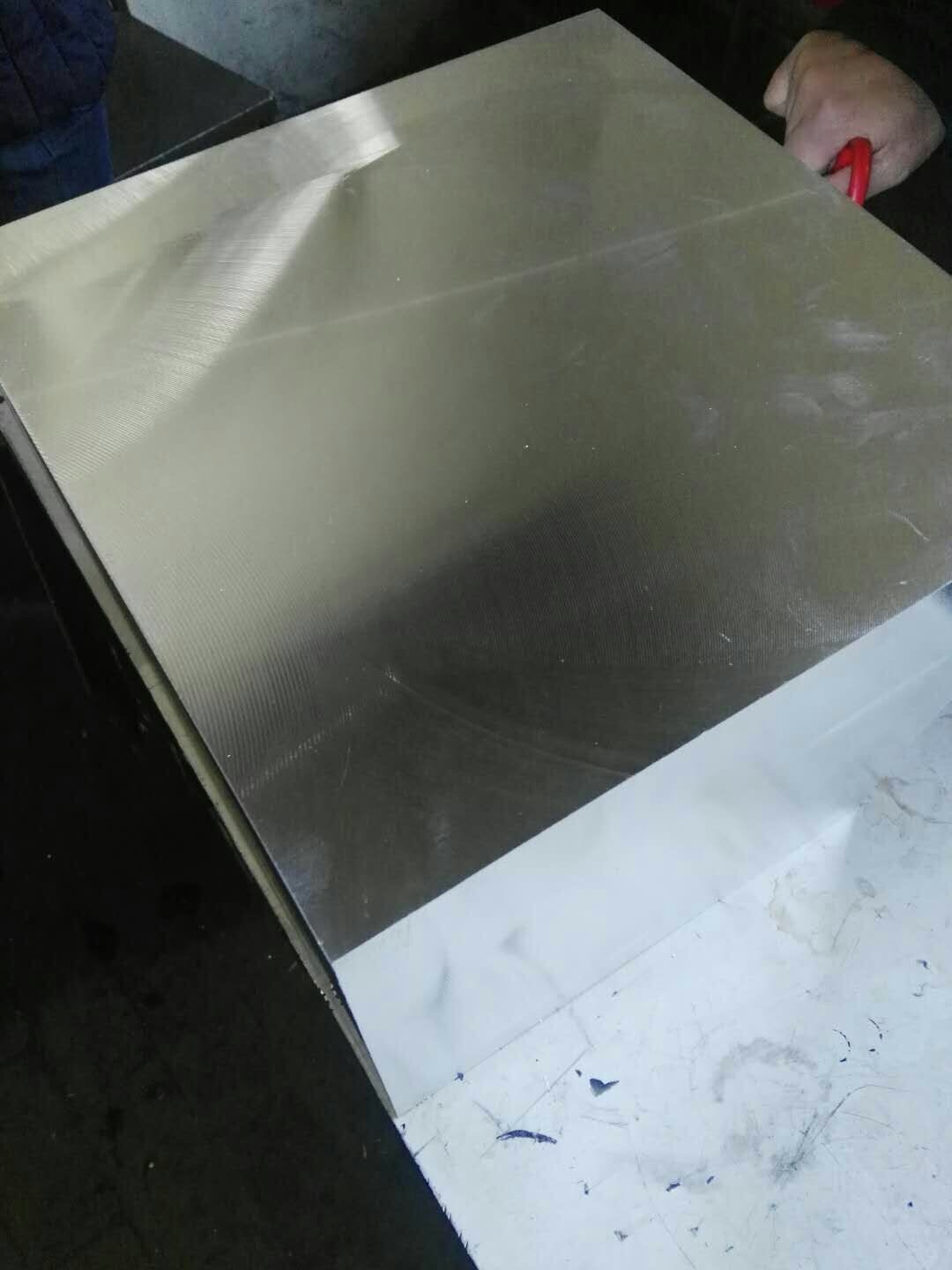

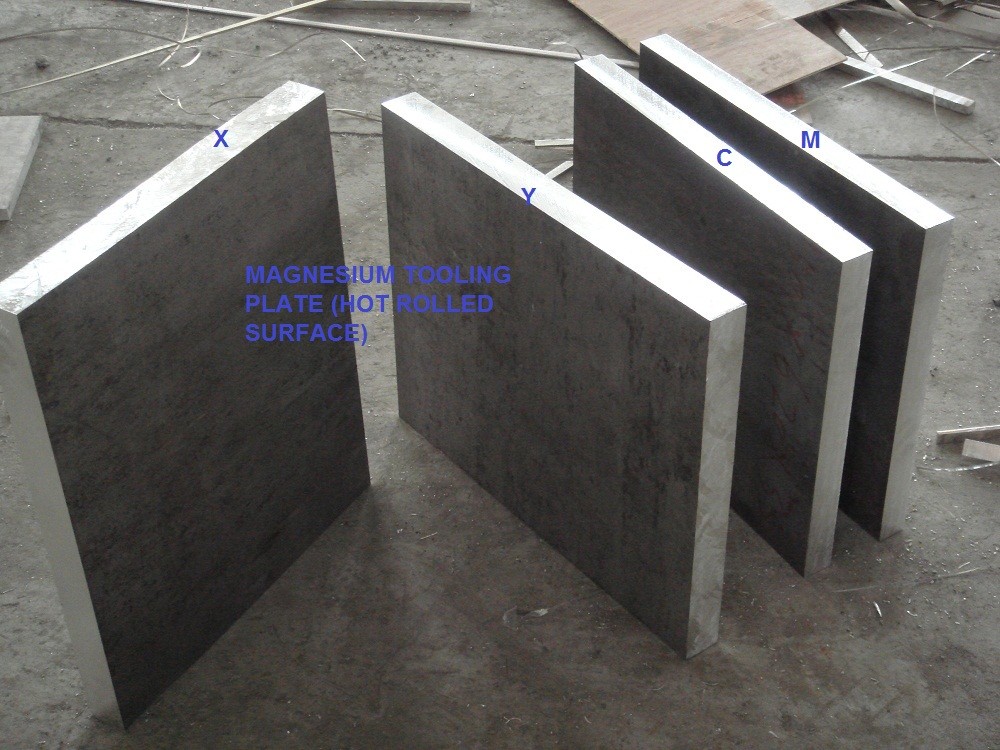

ZK60A-F magnesium alloy plate disc bar block with high strength and competitive price and fast delivery

ZK60A

ZK60A is a wrought magnesium base alloy containing zinc and zirconium. Increased strength is obtained by artificial aging from the as-fabricated form. ZK60A-T5 has the best combination of strength and ductility at room-temperature of the wrought magnesium alloys.

APPLICATIONS

Forgings and extrusions in ZK60A find application in high strength parts for use primarily where the service temperature is below 150°C. ZK60A forgings can be used where pressure tightness or machinability are required. That parts are dimensionally stable during and after machining is also an important design consideration.

Forgings and extrusions in ZK60A find application in high strength parts for satellites, helicopter gearboxes and rotor hubs, bicycle frames, roadwheels, missle frames and interstage fairings, brake housings and landing gear struts.

SPECIFICATIONS

ASTM B91

ASTM B107/B107M-13

CHEMICAL COMPOSITION

Zinc 4.8-6.2%

Zirconium 0.45% min

Magnesium Balance

Dimension Scope

Forgings: Max. length 1000mm, max. width 500mm, max thickness 330mm.

Extrusions: Diameter 6mm - 180mm for round bar; thickness and width 10-220mm for square/rectangular section. Length: 100mm - 6000mm

Thickness and width are inter-dependant.

HEAT TREATMENT

As-fabricated (F) forgings can be converted to the precipitation treated temper (T5) by heating to 150°C for 24 hours, followed by air cooling.

PHYSICAL PROPERTIES

Specific Gravity 1.83

Coefficient of Thermal Expansion 27.1x10 -6 K -1

Thermal Conductivity 121 Wm -1 K -1

Specific Heat 1100 Jkg -1 K -1

Electrical Resistivity 57 nΩm

Modulus of Elasticity 45GPa

Poissons Ratio 0.35

Melting Range 520-635°C

TYPICAL HARDNESS

ZK60A-T6 85 Rockwell E

ZK60A-T5 77 Rockwell E

WELDABILITY

ZK60A is not considered to be weldable by conventional techniques due to hot-shortness cracking. However, resistance welding response is excellent. Friction stir welding can be used to join ZK60A to itself and other magnesium alloys.

MACHINING

ZK60A, like all magnesium alloy forgings, machines faster than any other metal. Providing the geometry of the part allows, the limiting factor is the power and speed of the machine rather than the quality of the tool material. The power required per cubic centimeter of metal removed varies from 9 to 14 watts per minute depending on the operation.

SURFACE TREATMENT

All the normal chromating, anodizing, plating, and finishing treatments are readily applicable.

Xi'an Yuechen Metal Products. Co., Ltd. (XYMCO) - a manufacturer specialized in the magnesium tooling plate, Magnesium alloy plate, magnesium alloy slab, magnesium alloy sheet, magnesium alloy bar, magnesium alloy tube, magnesium alloy billet, magnesium alloy rod, magnesium alloy rod, magnesium alloy pipe, magnesium welding wire, magnesium alloy profile, magnesium alloy forging, magnesium alloy casting, magnesium alloy machining part.

We comply with the specifications: AMS 4377G, AMS 4382, ASTM B90/B90M and ASTM B107.

Material grades: AZ31B, AZ61A, AZ80A, ZK60, AM50, AM60, AZ91, EQ21, EZ33, EV31, WE43, WE54 and ZE41.

Our main products and capacities are as follows:

1. Magnesium tooling plate: Max. Thickness: 300mm; Max. Width:

3000mm; Max. Length: 6000mm

2. Magnesium alloy slab: Max. Size: 400 x 1000 x 2500mm

3. Magnesium alloy sheet: Min. Thickness: 0.5mm; Max. Width: 600mm;

Max. Length: 2000mm

4. Magnesium cast bar: Min. Diameter 90mm; Max. Diameter: 600mm;

Max. Length: 6000mm

5. Magnesium extrusions:

Round tube: Max. OD 600mmx thickness 125mm Square tube: 430 x 430mm

Flat bar: 920 x 160mm

U-Shape: 800 x 300mm Rectangular: 700 x 200mm

6. Magnesium alloy machined part according to customer’s design

7. Magnesium anode as per customer’s design

Our products already were exported to USA, Japan, Israel, India, Germany, Iran, Columbia, Italy and UK. Good quality, good price and good delivery.

Looking forward to your enquiry and hope a prosperous cooperation

can be established between us.

Applications of our extruded products:

The special characteristics of magnesium such as its light weight

and damping capacity make it therefore, a material that is readily

used in several different applications.

Automotive

| Engine blocks | Steering column parts | Seat components |

| Bed plates | Brake and pedal brackets | Roof panels |

| Transmission houses | Airbag retainers | Fuel tank covers |

| Transfer cases | Radio frames + heatsinks | Engine hoods |

| Head covers | Radio covers | Rear deck lids |

| Oil pans | Mirror brackets | Full magnesium doors |

| Knee bolsters | Door handles | Wheels |

| Steering wheels | Front ends | Radiator supports |

Sport and Leisure

| Luggage frames | Suit cases | Tennis rackets |

| Bicycle frames | Camping equipment | Snowshoes |

| Mountain bike frames | Eyewear frames | Bull floats |

Common applications

| Cellular phones | Multi-media housings | Camcorders |

| Antenna housing | Camera Housings | Electric shavers |

| Loudspeaker frames | Projector frames | Printers |

| Laptop Housings | Batteries | Headphones |

| Train Seats | Aviation components | Turbine engines |

| Truss constructions | Cargo floors | Powertools |

| Chain saws | Concrete trowels | Wall saws |

| Ladders | Scaffoldings | Shelves |

Our Advantage

Advantage

Full range of product types, Ensure production capacity:

We ave advanced die-casting, extrusion, forging, rolling, casting

processing production line and precision testing equipment. Can

produce a variety of types of magnesium alloy and magnesium alloy

products, and developed a high-strength magnesium alloy extruded

sheet. Through the purification of ordinary magnesium, magnesium

can be raised up to 99.99% of high purity.

Cost advantage:

Magnesium alloy casting production can customized as your

requirement. the technical process is great, extrusion production

required for a variety of bar, no need to purchase from abroad,

extrusion molding products is easy molding, low energy consumption,

saving production costs.

Our Services:

1. Small order quantity available

2. Professional engineering team and sales team

3. Payment: T/T & Western Union

4. OEM/ODM Supporttable

5. Free samples provided

6. Competitive price and high quality