Dongguan Xinding Mechanical Equipment Co.,Ltd |

|

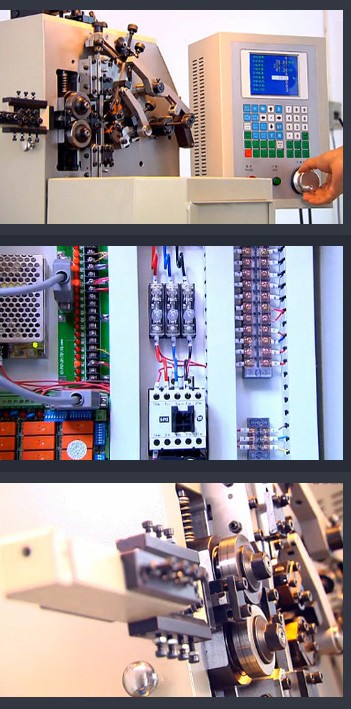

11 Axis Camless CNC Spring Making Machine With Spinner Motor , Stable Performance

| DETAIL DESCRIPTION |

| 1.Axis count: | 2 axis |

| 2.Wire size: | ¢2.00-5.00mm |

| 3.Max outside diameter: | ¢80mm |

| 4.Wire feed motor: | 7.0kw |

| 5.Cam motor: | 5.5kw |

| 6.Computer display: | Chinese/English |

| 7.Max wire feed: | 99999.99mm |

| 8.Min wire feed: | 0.02mm |

| 9.Computer memory: | 150 programs |

| 10.Dimensions: | 1400*1100*1900mm |

| 11.Weight: | 2450kg |

| 12.Power ac: | 3-phase 220v 50hz |

| PRODUCTION FEATURES |

Special camless design equipped with self-developed technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

Advance attachments such as rotary wire, spinner, and the x-y free

arm can be optionally equipped to the machine.

Intuitive graphics user interface.

Characteristic is due to the employment of a bullet proof software

engineering methodology. This makes learning and configuring highly

complex springs a simple task.

Commonly use in the industries of: automobile, wire forms,

entertainment and fitness.

| The company has always dedicated research and development, design, manufacture, sales and service in CNC spring machine equipment industry. | |

| We have professional teams, expert in production, design and R&D for over 10 years to meet clients' different demands. | |

| Our machine produce high presicion spring at 0.07mm wire diameter. |

| High precison and excellent performance for producing all kinds of springs and wire forms, Sanyo Denki servo motor for each machine axis, each axis is controlled by a seperate machine CNC. |  |

| Machine test run(at least for one week) is a must before we ship the machine, in an effort to insure every mechanical and electrical parts are in perfect condition. | |

| After order placed, we accept to adjust the products according to customer's demand, and remain the program and tool settings on machine. in order to insure a quick start of machine once customer receive it. |

| OUR FACTORY & OFFICE |

| TIPS ON MACHINE MAINTENANCE |

| CONTACT US |

| www.springxd.com |

| +86 13580987891 | |

| 0769-85560118 | |

| 0769-82883433 | |

| mr-bai | |

| sales@springxd.com, xinding@springmachine.net | |

| No. 7, Hongmian Road, Dabandi Industrial Park, Humen Town, Dongguan, Guangdong, China |

| FAQ |

| 1Q: Why us? |

| 1A: 13 years of experience in this line. All machines recieve good comments from customer. Independent R&D ability. Always happy to serve and work with our customers. |

| 2Q: What is the power supply of the machine? |

| 2A: The standard industrial power supply in China is 380V, 3-phase,

50hz, we can change the machine voltage according to customer's request. |

| 3Q: What information should the customer provide to get an accurate quotation from us? |

| 3A:The customer should provide the related technical requirements,

drawings, pictures, industrial voltage, planned output, etc. |

| 4Q: What is the payment term ? |

| 4A:The payment term is 30% down payment, and 70% before

shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc. |

| 5Q: What is the delivery time? |

| 5A: Normally the delivery time of the machine is 30 days after receive down payment. |

| 6Q: What is the warrantee period of the machine? |

| 6A: The warrantee period is two year since the date of shipment. |