Hongkong Winhoo Precision Co., Ltd |

|

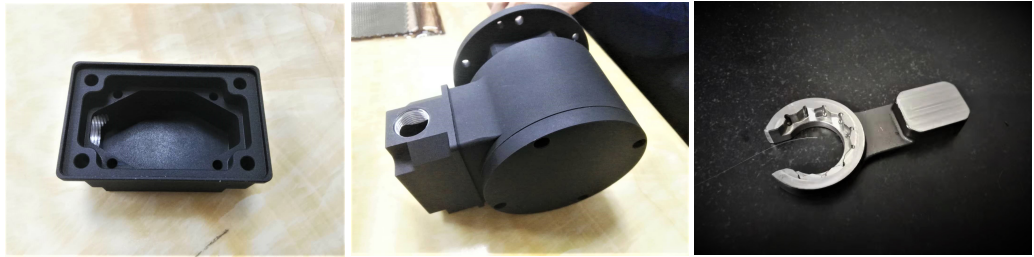

Customized Aluminium Die Casting Precision Cast Products For Agricultural machine parts

Product details:

OEM precision ADC12 Product Material Precision Aluminium Die Casting For Auto Parts /

Engines Generator parts

Material: ADC-12 Surface:Powder Coating Concentricity:0.05mm

Tolerance:0.03-0.1mm Flatness:0.05mm L*W*H(mm)=125mm*90mm*85mm

Main Product Display:

Metal:ADC-1,ADC-12,DIN 1706:231,DIN 1706:260,AlSi9Cu3,A380 A356,

Machine:Die casting machine

Suface treatment:dusting,baking finish,stoving

varnish,anodizing,sand blasting treatment

Purpose:Agricultural machinery, machine tool industry, electronic

industry, national defense industry,

computer, medical equipment, clocks, cameras, daily hardware, automotive accessories, furniture

accessories, bathroom accessories, lighting parts, toys, electrical and electronic

parts, belt buckles, watch case, metal buckles, locks, zippers,

Die casting is a metal casting process, which is characterized by the use of die cavity to exert

high pressure on molten metal. Moulds are usually made of higher strength alloys, which are

somewhat similar to injection moulding. Most die castings are iron-free, such as zinc, copper,

aluminium, magnesium, lead, tin and Lead-Tin Alloys and their alloys. According to the different

types of die casting, cold chamber die casting machine or hot chamber die casting machine are

needed.Traditional die casting process is mainly composed of four steps, or called high pressure

die casting. These four steps include die preparation, filling, injection and sand drop, which are

also the basis of various improved plate die casting processes.

Quality policy

Customer's requirement is our standard. In the long-term production process, we have

established a perfect quality management system, so that product quality can be controlled

steadily in the manufacturing process. We strictly enforce the operation rules and quality

standards from the aspects of material purchasing, R&D and design, process flow and

quality inspection, all of which originate from our unremitting pursuit of quality.

We can't give you the lowest price, we can only give you good quality. We would rather

explain the price to you for a while than apologize for the quality for a lifetime. If we only

want to pursue profits, we can achieve the goal of fast sales by reducing costs. But we think

that only perfect quality is our pride, in order to promise that we will not be proud of

short-term benefits. Selling the future, our efforts and persistence are recognized and

followed by more and more customers, which is the greatest driving force for us to continue

to move forward. We can not thank you, but only report quality.

| Quality Inspection Links and Inspection Items | Introduction of Various Quality Testing Instruments | ||

| 1.Inspection of raw materials | 3CMM | ||

| IQC Inspectors will inspect surface,size and matcertificate provided of materials. |  | CMM can be defined as "a detector which can move in three directions. |  |

▼ ▼

| 2.First sample inspection | 3CMM | ||

| Technicians and quality personnel will carry out self-inspection of the first sample, Batch production can not begin until the full size is qualified |  | Meanwhile length, width,height, verticality, parallelism, cylindricity and contour accuracy can be measured. |  |

▼ ▼

| 3.Process Inspection & Circuit Inspection | 2.5CMM | ||

| IPQC-checked regularly After start of mass production, we can find out influence of mechanical equipment changes and tool wear on size in time. |  | Usually takes the image into the computer through CCD for measurement and calculation. |  |

▼ ▼

| 4.Air tightness check, water pressure check | High Altimeterr | ||

| If you have assembled parts of product and required to inspect withstand pressure and leak inspection, we can do it. |  | High Altimeter (also known as altimeter) is used to measure the height of space points relative to the ground. |  |

▼ ▼

| 5.Final Inspection of Manufacturing Process | Micrometer | Calipers | |

| FQC is abnormal, it will be considered there is a quality problem between the inspection tour to final product. the FQC is an important link to ensure quality. |  |  |  |

▼ ▼

| 6.Full inspection of appearance and key dimensions | Comparator | Inner diameter micrometer | |

| All finished products will be inspected for scratches, bruises, debris, threads, burrs and other appearance problems. |  |  |  |

▼ ▼

| 7.Over Quantity Check | Pin gauge,block gaugeT | hread gauge, pass gauge | |

| OQC will carry out strict inspection according to drawings and quantity order. This inspection is also the last defensive wall to prevent the flow of defective products. |  |  |  |

▼ ▼

| 8. Fill in the quality inspection report | Material Sheet | Quality inspection report | |

| The results of actual measurement are collated and the quality inspection report is made. Delivery with goods to customers. |  |  |  |

▼ ▼

| 9. Packing | Rohs report | MSDS Sheet | |

| Finally, it is packed into special cartons or composite boxes to arrange related logistics and transportation |  |  |  |