Xiamen DingZhu Intelligent Equipment Co.,Ltd |

|

Verified Suppliers

|

|

Features of various polishing machines on the market

No

| project | DingZhu polishing machine | Robotic polishing machine | Special polishing machine | Remarks |

| 1 | quality | high | medium | low | |

| 2 | flexibility | Universal Angle, ensure that not deformation does not leakage | Universal Angle, ensure that not deformation does not leakage

| Easy to deformation and leakage

| |

3

| Wheel flexibility

| The wheel is large to ensure the line speed and the wheel is flexible

| The wheel is large to ensure the line speed and the wheel is flexible | The wheels are small and not very flexible enough

| |

| 4 | rigidity | Good steel, the wheels can be pressed tightly and polished

| Arms are too long, with poor steel performance | Good steel, the wheels can be pressed tightly and polished | |

| 5 | productivity | high | low | higher | |

6

| Add wax

| Solid wax, uniform, economical, and environmentally friendly | Liquid wax has a high cost, poor effect, and pollutes the equipment and the environment | Liquid wax has a high cost, poor effect, and pollutes the equipment and the environment | |

| 7 | Wheel loss | low | low | high | |

8

| self-compensating | Coordinate and line speed compensation effect is good | Without this function, it affects the quality | Without this function, it affects the quality | |

9

| frock

| Small quantity, simple structure, low cost | Small quantity, simple structure, low cost | The number is very large, complex structure, high cost | |

| 10 | Programming time | Within 2 hours | 8 Hours | 8 Hours | |

11

| Programming difficulty | Simple | Complicated | Complicated | |

12

| Change the product

| 15 Minutes | 2 Hours | 8 Hours | Previous production procedures exist |

| 13 | safety | high | medium | low |

DingZhu polishing machine product characteristics

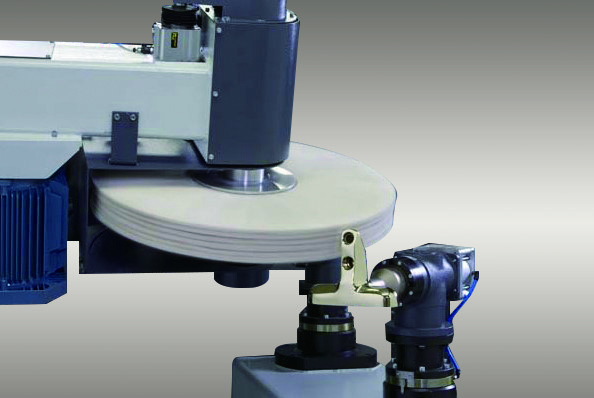

1. Automatic compensation function of polishing wheel: when the polishing cloth wheel is lost, the system can detect that the torque becomes smaller and realize automatic compensation in all directions.

2. Linear speed compensation: when the outer diameter of the cloth wheel decreases, the system automatically increases the speed compensation linear speed.

3. Solid wax addition: the original solid wax addition can freely set the wax addition time and frequency according to the characteristics of the product, and the polishing wax is not wasted.

4. Full digital control, the program can be saved and called at any time.

5. There are few fixtures, which can be replaced quickly and flexible universal, so as to reduce the loss of polishing cloth wheel.

6. The whole is polished evenly, and the quality of polished parts is consistent without deformation.

A fully automatic polishing machine that can replace 6 polishers to help you break through the bottleneck of die casting polishing

It can effectively improve the following aspects

1. Efficiency; It can be produced in 24 hours.

2. Quality: realize polishing standardization.

3. Save labor cost; The related expenses and management of personnel are controllable.

4. Safety and environmental protection, closed polishing production, equipped with dust suction interface,

5. The cost is controllable, the patented solid wax mechanism, and the cost of consumables is low.

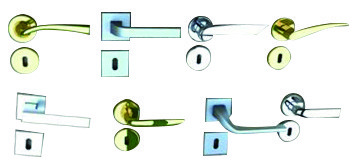

6. Polishing versatility, applicable to various shapes of zinc aluminum copper stainless steel materials.

TECHNICAL PARAMETERS

| No | Items | Specifications |

| 1 | Dimensions (L*W*H) | 3000*3100*2900mm |

| 2 | Machine Power | 17KW |

| 3 | Rated Voltage | 380V |

| 4 | Max. Diameter of polishing wheel | 600mm |

| 5 | Min. Diameter of polishing wheel | 400mm |

| 6 | X-Axis travel (mm) | 1100 |

| 7 | Y-Axis travel (mm) | 900 |

| 8 | Z-Axis travel (mm) | 700 |

| 9 | U-Axis travel (mm) | ±60° |

| 10 | V-Axis travel (mm) | ±360° |

| 11 | W-Axis travel (mm) | ±360° |

| 12 | Max.speed X axis | 20m/min |

| 13 | Max.speed Y axis | 20m/min |

| 14 | Max.speed Z axis | 20m/min |

| 15 | Max.speed U axis | 30°/sec. |

| 16 | Max.speed V axis | 30°/sec. |

| 17 | Max.speed W axis | 30°/sec. |