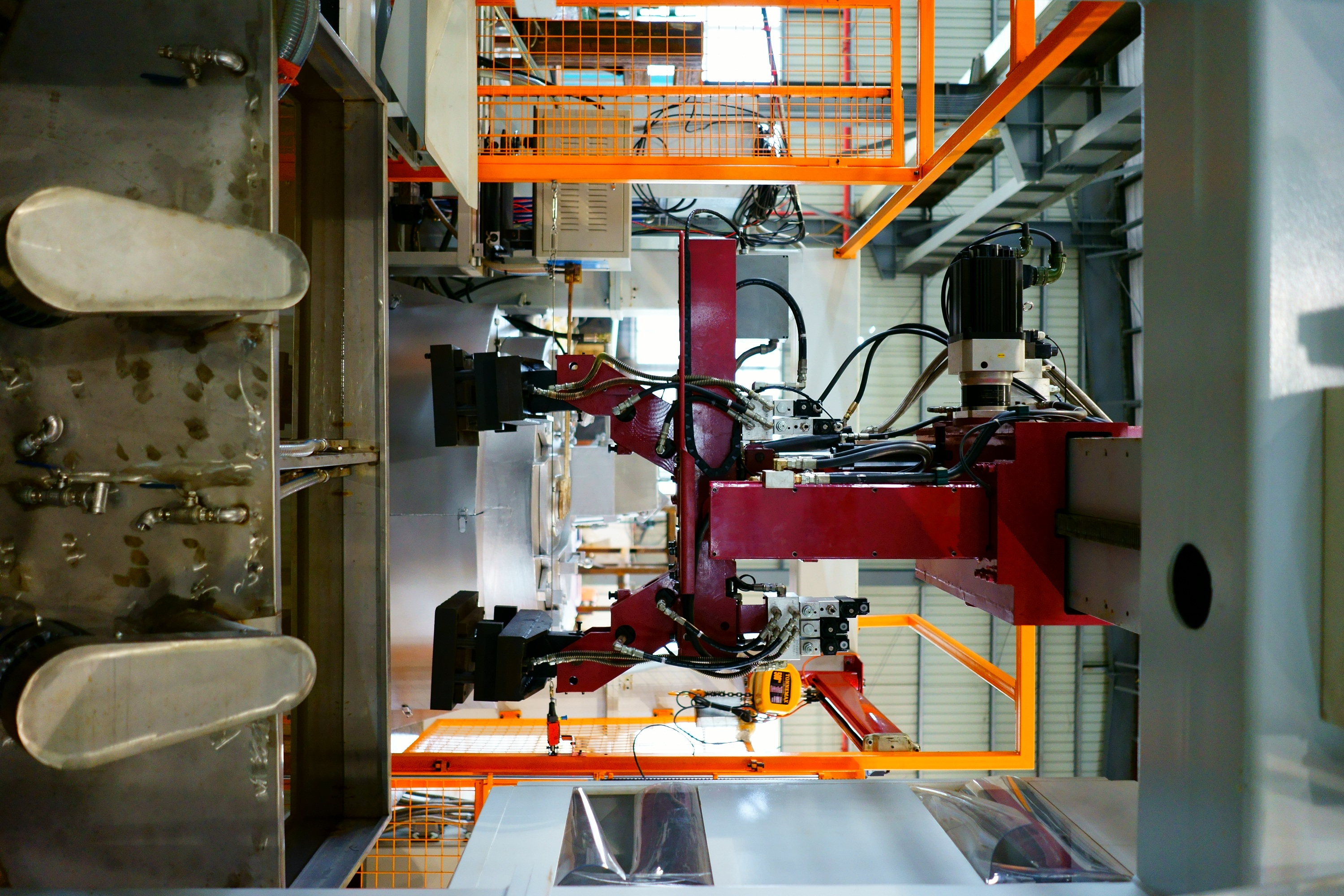

Xiamen DingZhu Intelligent Equipment Co.,Ltd |

|

Verified Suppliers

|

|

Advanages:

1. High quality casting and high-precision repeatability , automated casting with servo motor driving, linear guiding rail system;

2. High capacity ranges 400~450 castings per shift (8hrs);

3.Quick die change flange, 5 mins by munually ;

4. Furnace heating method: gas burner is standard and elctricity for option;

5. Max. die diemension 550*400mm;

6. Whole set machine cooled by cooling water for a efficiency cooling, highly improve inductors service life;

7. Zinc Oxide dust cleaning unit for furnace cleaning;

8. Industrial PC control with Ethernet cables, die casting programs up to 200 saved, recording & tracking furnace temperature;

9 .Cost-efficient production ( reduced melting loss,multiple die,one-man operation,increased yield);

10. Humanization of the work station (ergonomic design of the work station,minimizing of heat,noise and danger of accident)

| 1 | BASIC EQUIPMENT | ONE MANIPULATOR | TWO MANIPULTORS |

| 1.1 | INDUCTION FORNACE | ||

| CHANNEL INDUCTION FURNACE | 3 INDUCTORS | 3 INDUCTORS | |

| CAPACITY | 1800 KG | 1800KG | |

| MELTING CAPACITY | 350 KG/H | 520 KG/H | |

| POWER COSUMPTION | 3*35 KW | 2*80 KW | |

| POWER CONSUMTION @ TEMEPRATURE HOLDING 950℃ | 35KW | 35KW | |

| Max.Temp. of Furnace | 1250℃ | 1250℃ | |

| 1.2 | MANIPULATOR | 1, LINEAR GUILDING | 2, ROTARY |

| Max. Speed of Manipulator(S) | 20 meters/min. | 35° / Sec. | |

| 1.3 | HYDRAULIC AGGREGATE | SERVO MOTOR: 1* 7.5KW | SERVO MOTOR: 2*7.5KW |

| OIL | Ethylene glycol | ||

| CYLINDRES | Graphite: 63*100*2 sets Rotary: 63*215*1 set Lifting: 63*250*1 set Die Closing: 50*372*1 set Stroke: 32*50*2 sets | ||

| NOMINAL WORKING PRESSURE | 8MPa | ||

| HYDRAULIC OIL TEMPERATURE | ≤52 ℃ | ||

| 1.4 | WATER DISTRIBUTION UNIT | ||

| Cooling water for furnace coils, graphite bath and hydraulic system | |||

| PH value | 7~8.5 | ||

| Water Pressure | 3-5 bar | ||

| Water temperature | 20±2 ℃ | ||

| Water Flow | ≥15L/Min ≤80L/Min | ||

| 1.5 | AIR PRESSURE UNIT | ||

| Compressed air for die cleaning, pnematic valves, furnace cleaning, casting and security valves etc. | |||

| Compressed air pressure | 0.6Mpa | ||

| Compressed air consumption | 15㎥ /H | ||

| 1.6 | DRIVE UNIT | ||

| SERVO MOTOR: | 1* 7.5KW | ||

| 1.7 | FURNACE COVER | ||

| 1 RISER TUBE FLANGE | |||

| 2 PROTECTION TUBES FOR THERMOCOUPLES | |||

| 1 RISER TUBE | |||

| 1 CERAMIC SEALING | |||

| 1 CHARGING TUBE AND COVER FOR MANUALLY OPENING | |||

| 1.8 | GRAPHITE BATH | 1 | 1 |

| Temperature controlled coating bath, SS316L material | |||

| 1.9 | GAS BURNER | ||

| Gas burner mounted on the furnace cover for riser tube heating and pre-heating. | |||

| 1.1 | CONTROL AND POWER CABINET | ||

| PLC CONTROL | Siemens S7/300 | ||

| HMI (TOUCH SCREEN) | 1 | ||

| OUTER DIMENTIONS (L*W*H ) | 1200*500*1800mm | ||

| 1.12 | REMOTE SYSTEM | ||

| PC via Team Viewer and Internet connected | |||

| 2 | MAIN OPTIONS | ONE MANIPULATOR LD5540-D | TWO MANIPULTORS LD5540-S |

| 2.1 | PIECE REMOVAL UNIT | ||

| Automatically removal unit, equipped with a receiving car to transport the castings to storage trolley directly. | 1 | 1 | |

| 2.2 | SHOT BLASTING DEVICE | ||

| Copper powder blasting for dies cleaning; | 1 | 1 | |

| 2.3 | FILTER AND SUCTION UNIT FOR CASTING VALVE | ||

| For zinc oxid dust suction to cleaning furnace | |||

| 2.4 | CRANE WITH ELECTRIC HOIST | 500 KG | 500KG |

| 2.5 | PNEUMATIC OPENING OF THE CORE INSERTING WINDOW | ||

| Automatically opening by a pneumatic cylinder; Manually closing after core setting is finished. | |||

| 3 | ELECTRICAL OPTIONS | ONE MANIPULATOR LD5540-D | TWO MANIPULTORS LD5540-S |

| 3.1 | EMERGENCY POWER CONTACTOR | 1 | |

| With emergency stop buttons; for security purpose: there is automatic locked doors and complete fence unit. | |||

| 3.2 | SPECIAL CABLES | 10 M | |

| 4 | DIE OPTIONS | ONE MANIPULATOR LD5540-D | TWO MANIPULTORS LD5540-S |

| 4.1 | DIE FLANGES | ||

| 4.2 | TEMPERATURE MEASURMENT OF THE DIES | PID control | |

| 4.3 | TEMPERATURE MEASURMENT GRAPHITE BATH | PID control | |

| 4.4 | PUMP CIRCUIT FOR CONTINUOUS CLEANING OF THE GRAPHITE BATH | ||

| 4.5 | Max. Die Dimensions | 550*400mm | |

| 4.6 | Max. Die Thickness | 2-70mm | |

| 4.7 | Max. Die Opening stroke | 370mm | |

| 4.8 | Max. Die Weight | 200KG | |

| 4.9 | Max. force of die closing | 1500KG | |

| 4.1 | Max. force of ejector | 500KG | |

| 4.11 | Max. die ejector stroke | 50mm | |

| 5 | HEATING GAS OPTIONS | ONE MANIPULATOR LD5540-D | TWO MANIPULTORS LD5540-S |

| 5.1 | Propane Pressure | 0.5 bar | |

| 5.2 | Propane flow | 0.225 m3 / h | |

| 6 | UTILITIES OPTIONS | ONE MANIPULATOR LD5540-D | TWO MANIPULTORS LD5540-S |

| 6.1 | Equipment Size: L*W*H | 6500*6000*3400mm | 7000*7000*3687mm |

| 6.2 | Total Weight | 13T | |

| 6.3 | Total Power | 125KW | 180KW |

| 6.4 | Operating Voltage | 380V | 380V |

Click the link to view video: