Shenzhen Guanhong Automation Co., Ltd. |

|

1. Overview:

SZGH-CNC990TDc is 2-4 Axis Lathe and Turnning CNC Controller ,with 8.4 inches display(800x600) ,2 analog spindle ,2ms interpolation in high speed, support ATC , PLC and macro function. which obviously improve the efficiency,precision and surface quality of parts processing. New USB interface,it shupports the file operation and program running in flash disk.

| 1 | Axis No: | 2 axis with X & Z |

| 2 | Application: | CNC turnning machine and lathe machine |

| 3 | Programming: | International standard G code and macro |

| 4 | Updated function: | ATC function and tool magazine |

| 5 | Customized function : | OEM display screen with clients' company name and logo |

| 6 | Stronger function: | Online programming |

| 7 | Warranty time: | 2 years warranty time |

| 8 | maintenance: | lifetime maintenance, quality assurance |

2.Technical Specifications

Number of control axes

• Number of control axes: 2-4 axes

• Number of linkage axes: 2-4 axes

• Number of PLC control axes: 2-4 axes

Feeding axes function

• Minimum command unit: 0.001mm

• Position command range: +/- 99999.999

• Max speed: 30 m/minFeeding speed:0.001-15m/min

• G00 rapid override: Total 8 levels: 0~150%,real-time adjusting

• Feeding override: Total 16 levels: 0~150%,real-time adjusting

• Spindle override: Total 16 levels: 5%~150%,real-time adjusting

• Interpolation mode: Interpolation of linear ,arc ,thread and rigid tapping

• Auto chamfering

Thread

• Acceleration and deceleration funciton

• Common thread(follow the spindle) / Rigid thread

• Single-headed/Multi thread of straight ,taper and therminal suface in metric system/inch system,wqual and variable pitch thread

• Thread retractin length ,angle and speed characteristics can be set

• Thread pitch:0.1~1000.000mm or 0.1~99 tooth/inch

• Rapid traverse: linear type or S type

• The starting speed,finishing speed and time of acceleration and deceleration are set by parameter

Spindle function

• Analog voltage 0~10V output in two channels ,support two-spindle control

• Spindle encoder feedback in one channel,the resolution of spindle encoder can be set

• Spindle speed: It is set by speed parameter,max spindle speed also coressponding to 10V

• Spindle override: Total 16 levels: 5%~150%,real-time adjusting

• Spindle constant surface speed control

• Ragid tapping

Tool Function

•Tool length compensation

• tool nose radius compensation (C type)

• Tool wearing compensation

• Method of setting tools: Tool-setting in fixed position ,trial cutting tool -setting,return to reference point,auto tool setting

• Tool offset exexuting mode: Rewriting coordinate mode,tool traverse mode

Precision compensation

• Backlash compensation/Pitch error compensation in memory type

PLC function

• The refresh cycle: 8ms

• PLC program download by USB interface

• PLC program can be customized edit

• I/Os : 56*32 ; 40*24 I/O can be edit freely

Man-machine interface

• 8.4'' large screen real-color LCD , the resolution if 480 000

• Display in Chinese or English

• Display in two-dimensional tool path

• Real-time clock

• Operation management

• Operate mode: Edit, Auto, Manual, MDI, mechanical zero return, MPG/single step, program zero-return

• Operation authority of multiple-level management

• Alarm record

Edit program

• Program capacity: 32M

• Editing function: program/block/characters research ,rewriting and deleting

• Program format: ISO code,support Macro command programming,programming of relative coordinate ,absolute coordinate and hybrid coordinate

• Calling program: Support macro program ,subprogram

Community function

• RS232: Files of part program can be transmitted

• USB: File operationand file directly processing in flash disk,support PLC programs,flash disk of software upgrade.

Safety function

• Emergency stop

• Hardware travel limit

• Software travel limit

• Data restoring and recovering

• User-defined alarm hint

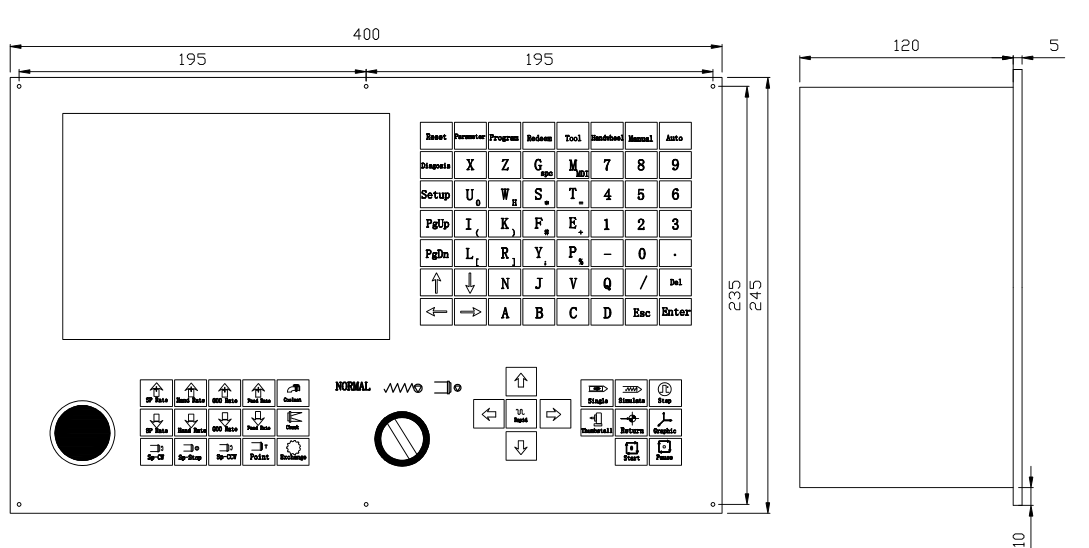

3.Product picture:

4.Application:

CNC lathe machinery; lathe center; wood working machine; numerically control grinder; MTDC applied to engraving CNC machine.

5.Appearance Dimension