Shenzhen Guanhong Automation Co., Ltd. |

|

Router / Drilling Cnc Machine Control System With Linear Type Or Bamboo Type Atc

Features:

1) The three axes of X,Y,Z control,three axes linkage movement.

2) 2ms interpolation cycle,1um precision.

3) 5MHz Output Pulse Frequency,Maximum speed: 300m/min,Feeding speed: 150m/min

4) Multiple function,it can realize the drilling/boring,roughing of roun groove/rectangle groove,finishing of full circle/rectangle,continuous drilling of straight line/rectangle/arc etc.

5) Built-in standard PLC program,and can be customized edited according to customer's asks.

6) Memory Capacity: 128MB,User Store Room: 110MB.

7) 8.4 inches (800*600) real colour LCD displayer.

8) Support Metric system/Inch System,with function of auto charfering.

9) Display in Chinese and English,which can be selected by paramter.

10) With USB interface,support USB file processing,software upgrade.

11) DNC in high speed,realize part program real-time transmission processing.

12) Analog voltage output of 0V~10V in two channels,support two-spindle control.

13) Support external MPG.

14) Basic I/Os: 56*40, 40*32 can be edited freely.

15) Support Incremental & Absolute type servo system & linear scale.

16) High anti-jamming switch power(220VAC -> DC 24V&5V)

| 1 | Axis No: | 3 axis with X Y Z |

| 2 | Application: | CNC milling machine and router , drilling machine |

| 3 | Programming: | International standard G code and macro |

| 4 | Updated function: | ATC function and tool magazine |

| 5 | Customized function : | OEM display screen with clients' company name and logo |

| 6 | Stronger function: | Online programming |

| 7 | Warranty time: | 2 years |

| 8 | maintenance: | lifetime maintenance, quality assurance |

Technical Specifications

1)Feeding axes function

| Minimum command unit | 0.001mm | ||

| Position command range | +/- 99999.999 | ||

| Max speed | 300 m/min | Feeding speed | 0.001-150m/min |

| G00 rapid override | Total 8 | levels | 0~150%,real-time adjusting |

| Feeding override | Total 16 | levels | 0~150%,real-time adjusting |

| Spindle override | Total 16 | levels | 5%~150%,real-time adjusting |

| Interpolation mode | Interpolation of linear ,arc ,spiral and rigid tapping | ||

| Auto chamfering | |||

2)Acceleration and deceleration function

| Cutting feeding | Acceleration and deceleration |

| Rapid traverse | Acceleration or deceleration |

| Tapping | set by parameter |

| The starting speed | |

| finishing speed | |

| time of acceleration and deceleration |

3)Spindle function

| Analog voltage 0~10V output in two channels ,support two-spindle control | |

| Spindle encoder feedback in one channel,the resolution of spindle encoder can be set | |

| Spindle speed | It is set by speed parameter,max spindle speed also coressponding to 10V |

| Spindle override | Total 16 |

| levels | 5%~150%,real-time adjusting |

| Spindle constant surface speed control | |

| Tapping cycle/ Ragid tapping | |

4)Tool Function

| Tool length compensation |

| tool nose radius compensation (C type) |

| Tool wearing compensation |

5)Precision compensation

| Backlash compensation | Pitch error compensation in memory type |

6)PLC function

| The refresh cycle | 8ms |

| PLC program download by USB interface | |

| PLC program can be customized edited | |

| I/Os | 56*32, 40*24 I/Os can be edit freely |

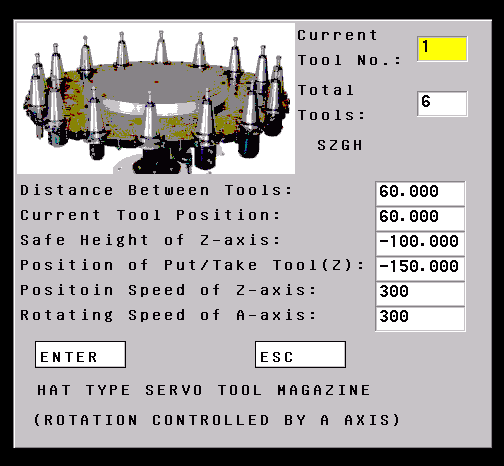

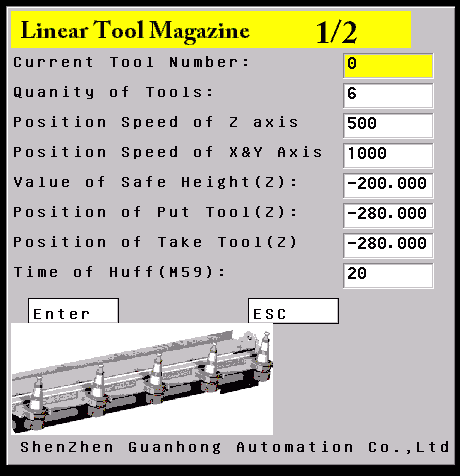

Support ATC function!!(Linear Tool Magazine)!

1) Umbrella or bamboo type tools

1) Linear type tools

Standard G codes list

G code | groups | function | ||

| G00 | 01 | Fast decides | ||

| G01 | The straight line inserts makes up | |||

| G02 | Inserts along the circle makes up/the spiral line to insert makes

up CW: The spiral motion spiral line inserts makes up the 2 circular

arcs insert makes up the axis synchronization migration other axes. The instruction method only is simply adds on is not the circular

arc inserts makes up the axis the shifting shaft | |||

| G03 | The counter circle inserts makes up/the spiral line to insert makes up CCW | |||

| G04 | 00 | pause | ||

| G15 | 17 | Polar coordinate instruction cancellation | ||

| G16 | Polar coordinate instruction: The polar coordinate (radius and

angle), the angle to is chooses the plane the first axis to anti-clockwise

changes, but the negative direction is clockwise changes . Form : G** G## G16 G00 IP G**Expresses the plane chosen G## mean G90Work piece coordinate system original point G91Current position Assigns the polar coordinate and zero point | |||

| G17 | 02 | Choose the X Yplane | XX axis or its parallel axis YY axis or its parallel axis ZZ axis or its parallel axis | |

| G18 | Choose the Z X plane | |||

| G19 | Choose the Y Z plane | |||

| G20 | 06 | Inch input | ||

| G21 | Millimetre input | |||

G28/G281/G282 /G283/G284 | 00 | Go to first reference point | ||

G30/G301/G302 /G303/G304 | Go to 2,3,4 reference point | |||

| G26 | ZXY axis go to program original point | |||

| G261 | X axis go to program original point | |||

| G262 | Y axis go to program original point | |||

| G263 | Z axis go to program original point | |||

| G264 | A axis go to program original point | |||

| G265 | B axis go to program original point | |||

| G40 | 07 | Cancel tool radius compensate | ||

| G41 | tool radius compensateleft | |||

| G42 | tool radius compensateright | |||

| G43 | Tool lenthen positive compensate | |||

| G44 | 08 | Tool lenthen negative compensate | ||

G45 | 00 | Tool adding offset | ||

| G46 | Tool subtact offset | |||

| G47 | Tool adding two multiple offset | |||

| G48 | Tool subtact two multiple offset | |||

| G49 | 08 | Cancel tool lengthen compensate | ||

| G37 | 11 | Cancel scale zoom | ||

| G36 | Enable scale zoomformatG36 X_Y_Z_R_ | |||

| G12 | 22 | Cancel programmer mirror | ||

| G11 | Enable programmer mirror | |||

| G52 | 00 | Set local coordinate | ||

| G53 | 14 | Chocie coordinate | ||

| G54 | Chocie work coordinate 1 | NoteThese six work coordinate save in CNCuser may choice any one | ||

| G55 | Chocie work coordinate 2 | |||

| G56 | Chocie work coordinate 3 | |||

| G57 | Chocie work coordinate 4 | |||

| G58 | Chocie work coordinate 5 | |||

| G59 | Chocie work coordinate 6 | |||

| G60 | 15 | exactitude stop | ||

| G64 | Continue path work | |||

G68 | 16 | rotate coordinateformat G17 G18 G68 a-b- R-; R:Angle G19 | ||

| G69 | Cancel rotate coordinate | |||

| G73 | 09 | Drill deep hole cycleformat G73 X-Y-Z-R-Q-F- L - Zdistance from R to hole bottom Rdistance from original to R Qfeed depth every time Ffeed speed Lrepeat time | ||

| G74 | Left Tap cycleformatG74X-Y-Z-R-P-F- L - | |||

| G80 | Cancel cycle mode | |||

| G81 | Drill cycleformat G81 X-Y-Z-R-F- L - | |||

| G82 | Drill cycleformatG82 X-Y-Z-R-P-F- L - | |||

| G83 | Drill cycleformat G83 X-Y-Z-R-Q-F- L -P- | |||

| G84 | Right Tap cycle formatG84 X-Y-Z-R-P-F- L - | |||

| G85 | Drill cycleformat G85 X-Y-Z-R-F- L - | |||

| G86 | Drill cycleformatG86 X-Y-Z-R-F- L - | |||

| G89 | Drill cycle G89 X-Y-Z-R-P-F-L- | |||

| G90 | 03 | Absolute program | ||

| G91 | Increase program | |||

| G98 | 10 | Go back to origorinal point | ||

Appearance Dimensio