Zhangjiagang Huipu Machinery Manufacturing Co., Ltd |

|

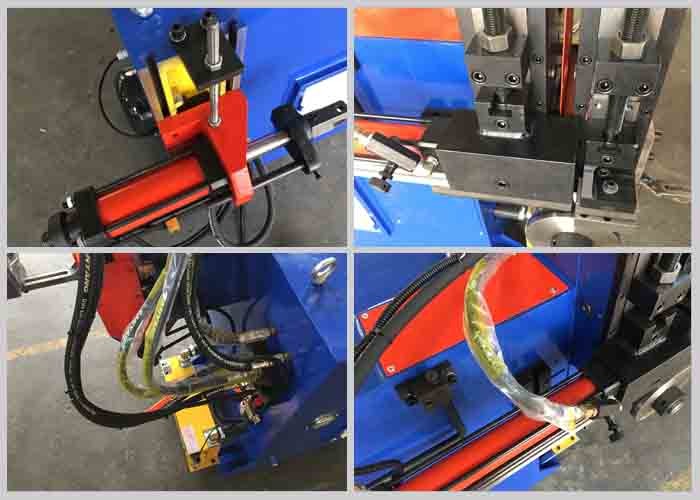

Semi automatic pipe bending machine with co-push installation for stainless steel tube

-- Description of machine

This machine is equipped with hydraulic drive, and it's electrical control system adopts touch screen control, text control and PLC centralize control program. It is equipped with a clamping tube, guided mode, input core, wrinkle-free, auxiliary pushing and bending device. Hydraulic pipe bending machines are mainly used for installing pipelines and repairs in factories, warehouses, docks, buildings, railways, and automotive industries. In the process of pipe bending, the outer diameter and thickness of different pipes and the different bending radius directly lead to the different bending moment of the pipe.

Therefore, the design of the pipe bending machine needs to calculate and determine the bending moment of the pipe first. The hydraulic pipe bending machine is a new type of pipe bending tool with an elbow function and a lifting function. It has the advantages of reasonable structure, safe use, convenient operation, reasonable price, fast loading and unloading, portability and multi-purpose use.

-- Machine characteristics

1. We can supply wide range of machines for the bending of the pipes with O.D. from 20mm to 200mm. We also supply the know-how for pipe bending to our customers.

2. Adopting solenoid valve and integrated circuit to control each motion separately. That extends the life of the parts of hydraulic system.

3. The pipe bending machine adopts a touch screen and a numerical control module. The dialogue operation makes the program easy to set up.

4. In the hydraulic system of the pipe bender, the main oil cylinder, the main clamping cylinder, the guide cylinder and the material clamping cylinder are all controlled by hydraulic check valve, which reduces the pressure loss and ensures the bending, clamping and pressing action in the bending process.

5. The one-way throttle loop is used in the main oil cylinder, the main clamp cylinder, the guide cylinder and the mandrel cylinder, which makes the system speed adjustable and meets the different pipe bending process.

-- Specifications of machine

| Maximum applicable carbon steel pipe | Φ38*1.5t |

| Maximum applicable stainless steel pipe | Φ32*1.5t |

| Maximum applicable copper pipe | Φ45*2.0t |

| Maximum coring length | 1700mm |

| Maximum bending radius | 200mm |

| Maximum bending angle | 190° |

| Settable bending pipe number of each pipe fitting | 15 |

| Motor power | 4KW |

| Maximum oil pressure | 14MPa |

| Weight | 830kg |

| Dimension | 2500*750*1300mm |

-- Applicable industry

Recommended application industry: automobile fittings, oil pipe for brake, muffler, seats, motorcycle fittings, healthy equipment, air-conditioning, bicycle, steel furniture, sanitary wares and so on.

Automobile fittings, brake lever, silencer, seats, motorcycle, body-building equipment, air conditioner, bicycle, steel-made furniture, sanitation equipment and other manufacturing trades.

-- Packaging and service

1. Payment terms: 30% T/T down payment and 70% T/T before shipment.

2. Delivery time: No later than 15 days since receiving the advance payment.

3. Validity of the price: For ONE month.

4. Package: Wooden case.

5. Warranty period: We guarantee machine quality for 12 months. During this period, if spare parts of the machine were damaged, we can send the component to the customer by international express service freely.

6. We can send our engineers to the customer’s factory to install and train for using freely. The customers just need to provide the double trip tickets, food and accommodation for our engineers. The customer can also send your staff to our factory to learn the operation and maintains freely.

7. Our factory provides service for customers forever, if the customer needs operation help or technical guidance, you can contact us by Email or telephone at any time, we provide 24 hours on-line service.

-- Pictures of machine