Weifang Donho Machinery Co.,Ltd |

|

Linear Guideway Cooling and Waste Box CNC Milling Machine For Machining Metal Castings Plumbing Fittings Products

Advantage

1. Each piece of the cover can be connected with the same movement, which is completely different from the general cover and one piece pulls, so the noise is extremely low;

2. the use of the device's shield can increase the service life;

3. The steel shield device can increase the moving speed of the shield to 120m/min and withstand a higher G value (2G);

4. the steel plate shield device makes the shields move and parallel (avoid the general shear force shield is still a shortcoming of snakes);

5. can be more stable at high speed, no vibration.

Specifications

| Type | unit | DHVMC-850 | |

| Table | Table size | mm | 1000*500 |

| Max. load of worktable | kg | 400 | |

| T slot no./width/distance | mm | 18x5x90 | |

| Travel | X axis travel | mm | 800 |

| Y Axis travel | mm | 500 | |

| Vertical travel | mm | 500 | |

| Spindle | spindle nose to table surface | mm | 150-650 |

| Spindle driver | - | Belt transmission | |

| spidle axis to column surface | mm | 572 | |

| Speed Range | rpm | 10,000 | |

| Spindle head casing aperture | mm | φ140mm | |

| Spindle taper | Type | BT-40 | |

| Auto tools change | Maximum tool diameter | mm | Φ80(Φ130) |

| Maximum tool length | mm | 300 | |

| Maximum tool weight | kg | 8 | |

| Shank | Type | BT-40 | |

| Tool magazine capacity | Pieces | 24 | |

| Tool exchange method | - | Knife arm | |

| Tool exchange time (knife-to-knife) | Sec | 1.8 | |

| Rivet | Type | P40-1( 45°) | |

| Motor capacity | Controller | Syntec 22MA | |

| battery capacity | kVA | 25 | |

| Servo motor (X/Y/Z) | kW | 2.6/2.6/3.0 | |

| Cutting fluid pump | w | 840 | |

| Spindle motor (continuous / 15 minutes) | kW | 7.5/11 | |

| Automatic lubrication device | w | 35 | |

| Others | Air source pressure demand | kg/cm | 6 |

| Cutting water tank capacity | L | 250 | |

| positioning accuracy | mm | 0.01 | |

| Repeatability accuracy | mm | 0.008 | |

| Floor area and height | mm | 2550*2250*2400 | |

| Machine weight | kg | 5000 | |

Machine Details

Auto Chip conveyor

The device has the advantages of serialization, generalization and standardization, simple operation, reliable operation, convenient disassembly and assembly, and easy maintenance. It can also be used in conjunction with other chip evacuation devices to form a variety of cutting arrangements.

1. It can handle all kinds of chips; it can also be used as a conveying device for small parts of stamping and cold pier machine tools.

2. High conveying efficiency and large selection range of conveying speed;

3. The width of the chain plate is diversified, and the structural form is divided into two types: a seamless chain plate and a seam chain plate. 4, streamlined shape, beautiful appearance, smooth chip removal;

4. With overload protection.

Oil cooled system for spindle

1. Oil temperature control is based on the body temperature (room temperature). The user can set the oil temperature according to the temperature of the body to prevent thermal deformation of the mechanical structure.

2. Immersed oil cooling and temperature control device is free from impurities, is not interfered by cutting metal powder, etc. It is easy to clean and easy to maintain; it is easy to install and does not take up space.

3, with automatic fault alarm function, can promptly remind the user to repair the device in a specific way, so as to avoid damage to the machine.

Automatic lubrication system

The automatic lubrication system solves the machine fault caused by the frequent lubrication in the long-term use of the machine, and has the lubrication system alarm function. The lubrication method is simple and reliable, and the oil lubrication and circulation time can be automatically adjusted according to the working state of the machine tool to save lubricating oil. It is automatically lubricated at start-up and can be lubricated according to the time interval set by the user. The automatic lubrication system is designed with overload detection, oil level detection and pressure detection to prompt the operator to stop the inspection.

Auto Chip conveyor

The device has the advantages of serialization, generalization and standardization, simple operation, reliable operation, convenient disassembly and assembly, and easy maintenance. It can also be used in conjunction with other chip evacuation devices to form a variety of cutting arrangements.

1. It can handle all kinds of chips; it can also be used as a conveying device for small parts of stamping and cold pier machine tools.

2. High conveying efficiency and large selection range of conveying speed;

3. The width of the chain plate is diversified, and the structural form is divided into two types: a seamless chain plate and a seam chain plate. 4, streamlined shape, beautiful appearance, smooth chip removal.

4. With overload protection.

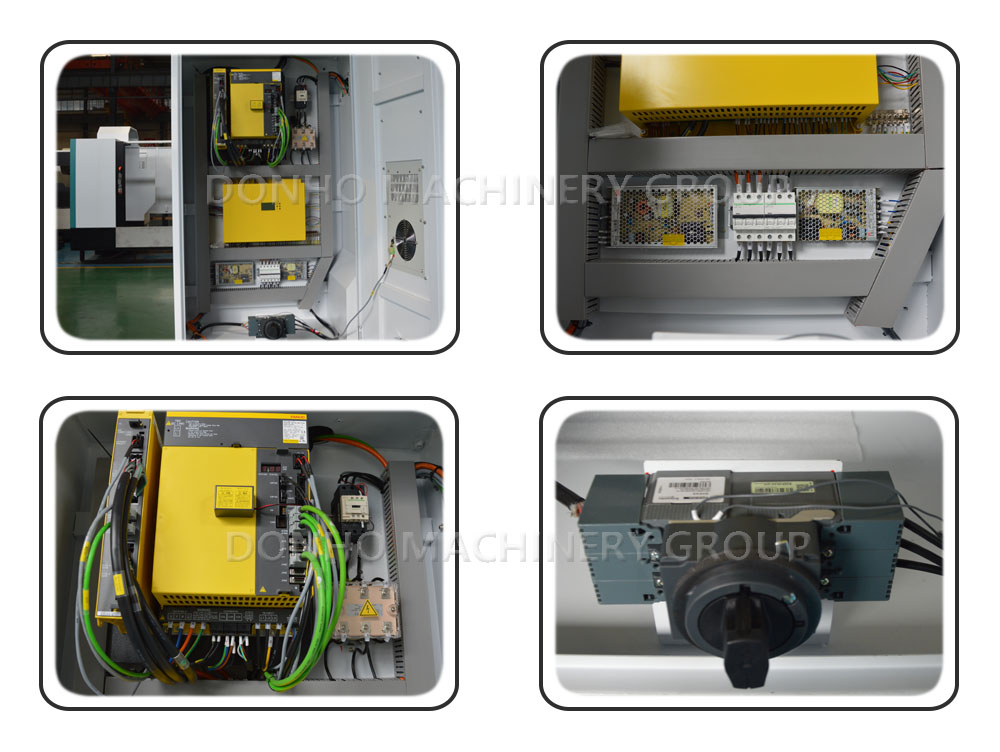

FANUC Spindle motor

High performance AC spindle motor with excellent basic performance

High processing performance

The optimized winding design and high efficiency cooling structure provide the motor with robust and agile acceleration in high speed areas.

By increasing the rated power and torque for a short period of time, the heavy cutting capability in a short time is enhanced, thereby shortening the acceleration and deceleration time.

The new through-hole model allows for central through-cooling, with air-cooled and liquid-cooled series.

High mechanical precision and low vibration characteristics for direct connection to the spindle.

With a maximum power of 200 kW and a maximum torque of 2000 Nm, it is suitable for large machine tools. The technology of driving several axes with multiple standard amplifiers to drive one axis can further address the need for high power.

Through the spindle control technology independently developed by FANUC, it can output the same S6 rated power as the rated power of S3.