Henan Yuanda Boiler Co.,Ltd |

|

Industrial Automatic Feeding 2000kghr Paddy Rice Husk Fired Boiler

For Rice Mill

Brief intrduction:

Yuanda SZL series product has a double tanks offset hearth (D-type

layout), great apply for coal, as well as biomass fuel,

environmental protection and energy conservation, and is a key

promoted product of national energy-saving projects. Honors of

Yuanda SZL D Type boiler :

1. National Scientific and Technological Progress Second Prize

2. Singapore New Product Expo Golden Lion Award

Application fields:

1.Food beverage industry: such as rice mills, noodle factory,

canned factory, juice processing factory, tomato sauce factory,

beer wine factory, etc.

2.Textile industry: textile factory, garment factory, sweater

factory, socks industry, dyeing factory.

3. Petrochemical industry: steam can be used to heat oil, to

strengthen the liquidity of oil;

4. Foam, furniture production: the steam can be used for producing

foam. When making furniture, wood needs to be dried with steam;

4. Filling block production:steam used for drying the aerated

brick;

5. Washing ironing industry: generally used in laundry, including

dry cleaning machines, dryers, washing machines, dehydration

machines, ironing machines, iron and other equipment supporting the

use;

6. Packaging machinery industry: labeling machines, sets of

standard machine;

Basic specifications of SZL 2000kg rice husk fired boiler:

| No. | Name | Unit | Data | ||||

| 1 | capacity | t/h | 2 | ||||

| 2 | Rated Pressure | Mpa | 1.25 | ||||

| 3 | Feed water temperature | ℃ | 20 | ||||

| 3 | Steam temperature | ℃ | 194 | ||||

| 4 | Hydraulic test pressure | Mpa | 1.65 | ||||

| 5 | Water volumn | m3 | 7.24 | ||||

| 6 | Exhaust smoke temperature | ℃ | 142 | ||||

| 7 | Design efficiency | % | 86 | ||||

| 8 | Fuel consumption | kg/h | 347 (@17.69MJ/kg) | ||||

| 9 | Fuel lowest heat value | MJ/kg | 17.69 | ||||

| 10 | Applied fuel | biomass, rice husk, bagasse, palm kernel shell, sawdust | |||||

| 11 | Radiation heating area | ㎡ | 10.15 | ||||

| 12 | Convection heating area | ㎡ | 55.3 | ||||

| 13 | Economizer heating area | % | 32.4 | ||||

| 14 | Grate active area | / | 3.17 | ||||

| 16 | Smoke blackness | <1 | |||||

| 17 | Boiler main part dimension | mm | 5960×2700×3470 | ||||

| 18 | Boiler main part weight | ton | 20 | ||||

SZL 2000kg rice husk fired boiler design features:

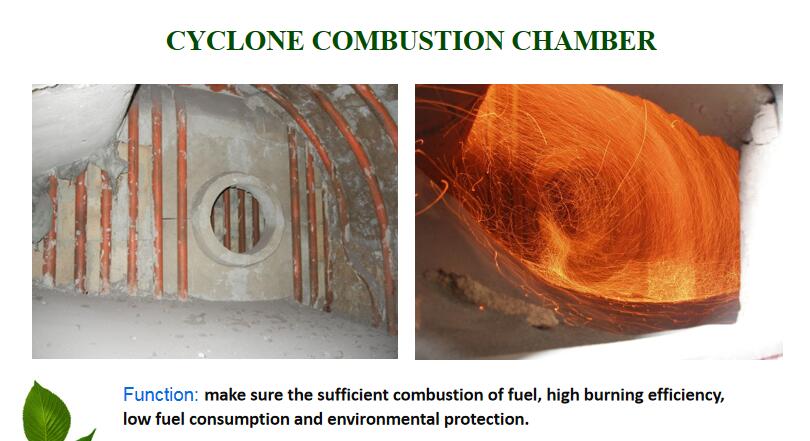

1. The cyclone combustion chamber is designed in the furnace. The high-temperature flue gas is rotated by high-speed rotation, mixed combustion and dust separation, so as to achieve the first-class dust removal, energy saving and environmental protection effects .

2, the furnace volume is large, can be applied to a variety of biomass fuels;

3. Independent air chamber structure makes the air volume adjustment between the longitudinal air chambers sensitive and reliable, and the horizontal air distribution is uniform, which overcomes the wind plug, hurricane and partial burn phenomenon;

4, the heating area is large, the pressure is fast, the output is sufficient, and the energy consumption is low;

5, package type delivery from factory, which can greatly shorten the installation time.

Boiler system: we provide this biomass steam boiler with

full set auxiliaries.

| Number | Item | Brand | Number | Item | Brand |

| 1 | Boiler proper | Yuanda | 8 | Induced fan | |

| 2 | Fuel feeder | 9 | Steam header | ||

| 3 | Electric control box | Yuanda | 10 | Feed water pump | |

| 4 | Economizer | Yuanda | 11 | Deaerator | Yuanda |

| 5 | Water treatment | Fleck | 12 | chimney | Yuanda |

| 6 | Water tank | 13 | Slag remover | ||

| 7 | Forced fan | 14 | Instrument&valves | ||

| 8 | Grate speed reducer | 15 | Cyclone Dust Collector |

Strict Quality Control:

1. All materials should be inspected before prodcution and each

steel have its ID code which can trace its quality test.

2. 100% Non-Destructive Inspection report of steel plate tube &

welding rod.

3. Hydraulic test: make sure strength and tightness of pressure

parts.

4.Third part inspection report: By China Henan Boiler Inspection

Institute.

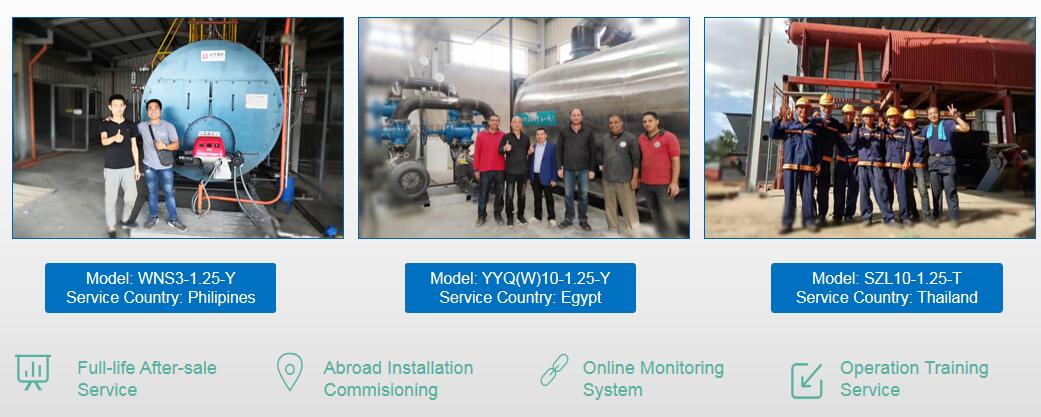

After-sale service:

1. provide full range of original spare parts.

2. We will send engineers to your local project site to guide the

installation and commissioning.

3. Our engineers will held a training for boiler workers to ensure

the safe operation.

4. Free maintenance and repair for one year and lifelong service.

FAQ

Q1: How can you get the best price quickly?

(1) We need to know the boiler capacity, the fuel you plan to use

and the steam pressure you need, and then we can confirm the boiler

model. (2) Customer needs to provide us your name, email address

and company name, and then we will send you price list

immediately.And if you use whatsapp, skype or wechat, you can

provide us your ID, it will be more convenient

for our communication.

Q2: Why should you believe our boiler quality?

(1).Strength calculation report with applied materials information;

(2).100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3).100% X-ray inspection(welding seam): ensure the quality of entire boiler;

(4).Hydrostatic test: ensure the standard working pressure and safety;

(5).Third-party inspection report:By Henan Boiler Inspection Institute;

(6).Passed ISO:9001 and SGS certificate.

Q3: What about the installation and Commissioning?

After you receive the boiler, we will guide you to make some

preparation for installation;If necessary, our expert will fly to

your local place in 72 hours. The experts will responsible for

guiding installation and commissioning.

But the buyer will be in charge of :

(1) The round air-tickets costs from Zhengzhou city to your project site.

(2) Board and lodging of seller's workers for entire period at the end user's site.

(3) Service fee for guiding engineer:100$/day/person.

Q4:What is the using life of your boiler?

A:Normally the boiler is designed for 20 years life span, but with

right operation and good maintenance,the boiler can be used for

20-25 years.